Field returning method for crushing corn straws, mixing crushed corn straws with soil, humidifying and extruding to form composite pipe for underground irrigation

A technology of composite pipes and corn stalks, applied in the directions of botanical equipment and methods, applications, presses, etc., can solve problems such as difficulty in comprehensive promotion, inability to meet crop moisture requirements, insufficient precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

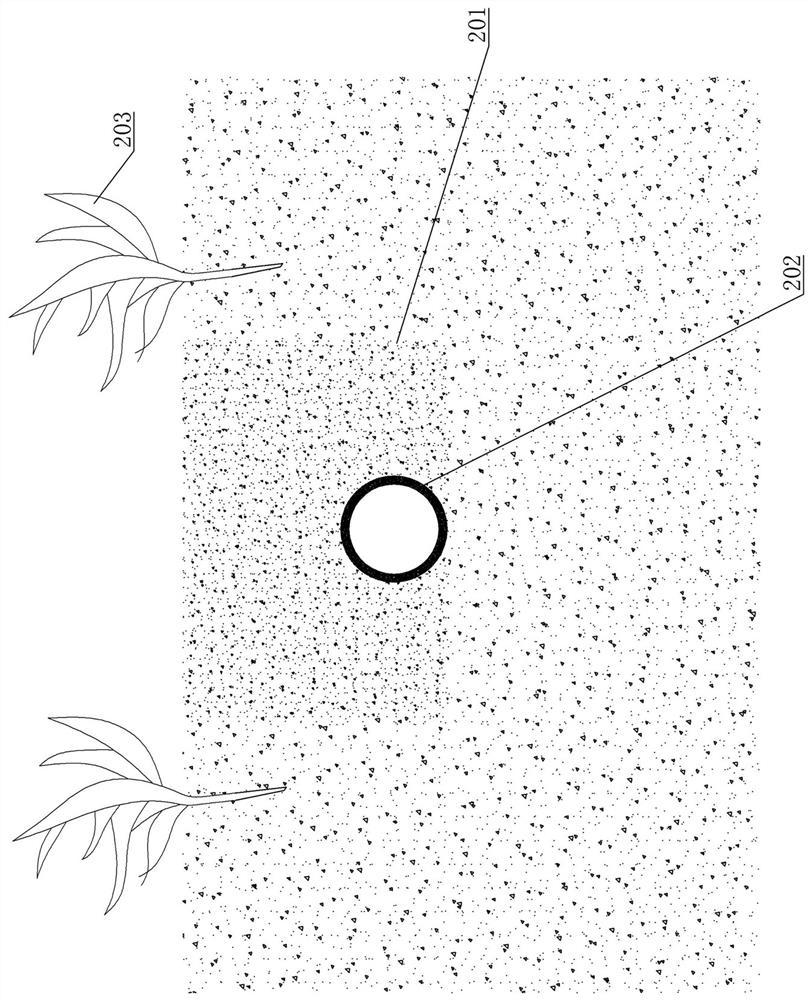

[0054] Embodiment one, refer to the description attached Figure 1-22 A method for returning corn stalks to the field for underground irrigation by mixing crushed corn stalks with soil, humidifying and extruding them into composite pipes, comprising corn stalks, soil, and water, comprising the following steps:

[0055] Step 1. Preparation of corn stalk fiber: After the corn stalk is naturally air-dried, it is crushed into straw debris with a crushing device;

[0056] Step 2. Preparation of materials for making composite pipes: Put a certain proportion of soil and straw debris into the stirring device for stirring and mixing, and continuously add water to the stirring device to increase the humidity. The combination of water, straw and soil can form viscosity higher mixture until a moist soil-straw mixture is formed;

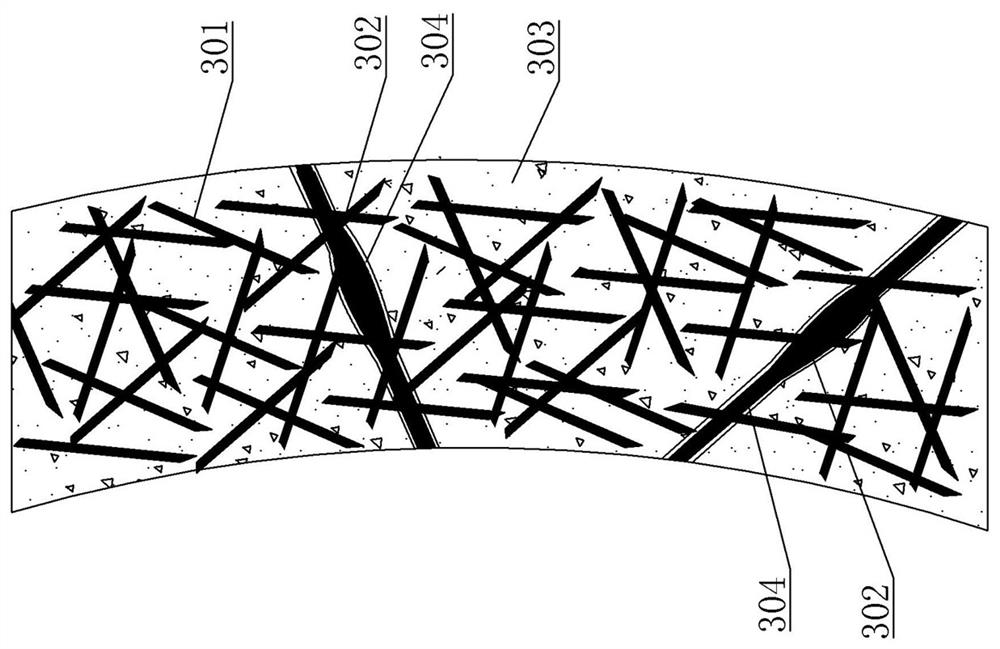

[0057] Step 3. Making composite pipes: Put the moist soil straw mixture into the pipe extrusion device to make composite pipes. The side walls of this composite...

Embodiment 2

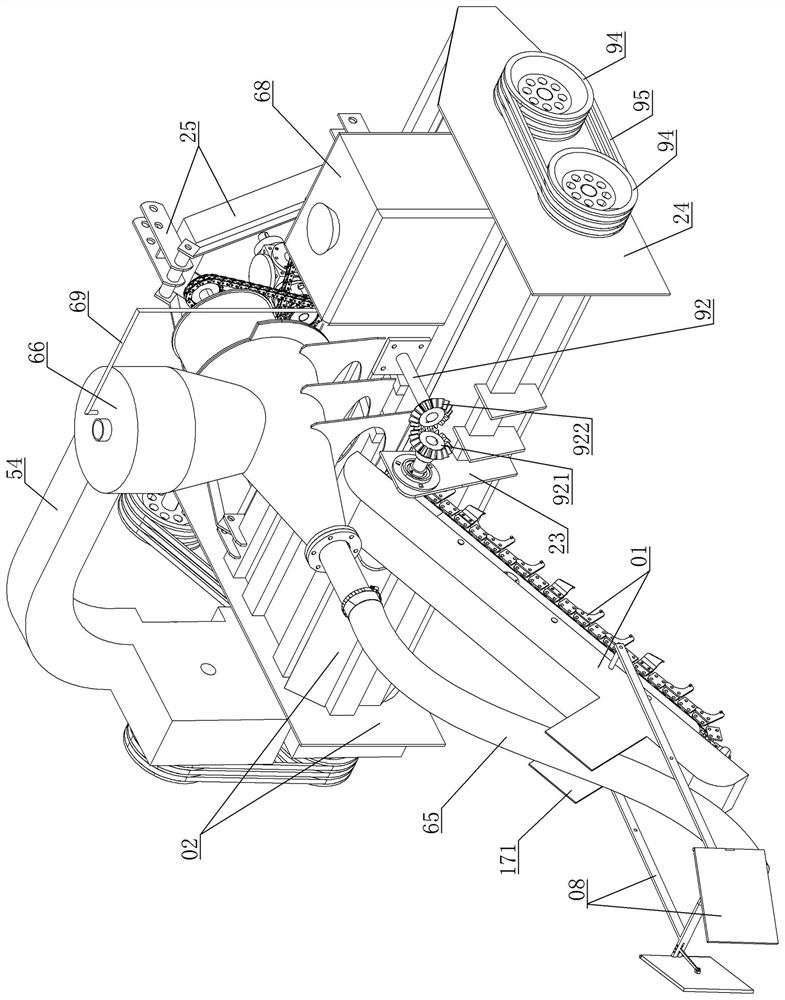

[0067] Embodiment two, refer to the appended Figure 3-22 , an integrated pipe-making and field-returning equipment, relying on this equipment to complete the specific implementation of steps 1 to 4 in Embodiment 1, the equipment includes a cutter shaft and an auger installed in the housing bracket, and one end of the housing bracket The installed secondary crushing conveying device, the power transmission device installed at the rear of the shell support, the equipment also includes a ditching device installed in the middle of the front end of the shell support, and a conical extrusion device installed in the middle of the upper end faces between the shells , the middle of the rear end of the shell bracket is provided with a hitch;

[0068] The cutter shaft and the auger are rotated side by side and connected in the housing bracket, the two ends of the auger and the cutter shaft are equipped with pulleys, the auger is located at the front end of the housing bracket, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com