Landfill leachate sludge dewatering composite biological enzyme conditioner as well as preparation method and use method thereof

A composite biological enzyme, sludge dewatering technology, applied in water/sludge/sewage treatment, sludge treatment, polluted groundwater/leachate treatment, etc. , the difficulty of deep dewatering of landfill leachate sludge, etc., to achieve the effect of increasing the dryness of the sludge and increasing the filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh the leachate sludge sample to be conditioned at 10m 3 In the plastic bucket, the sludge is taken from before entering the sludge thickening tank, add a certain amount of sludge conditioner, and stir continuously for 90-150 minutes under the condition of 30-50°C, and the stirring speed is 60-80 rpm. Then add a PAM solution with a concentration of 0.1% and continue to stir for 45-60 minutes. After precipitation, use laboratory filter press equipment to squeeze, the pressure is controlled at 0.5MPa, press filter for 5 minutes, and use 5000g of aqueous sludge for each experiment. The experimental results As shown in Table 1 below:

[0041] Table 1: Dryness of leachable sludge after adding sludge conditioner

[0042] serial number formula Conditioning agent ratio (%) PAM ratio (%) Dryness of sludge after press filtration (%) blank 0.5 34 1 A 0.005 0.5 46 2 B 0.005 0.5 47 3 C 0.005 0.5 47 4 A 0.01 0.5 52 ...

Embodiment 2

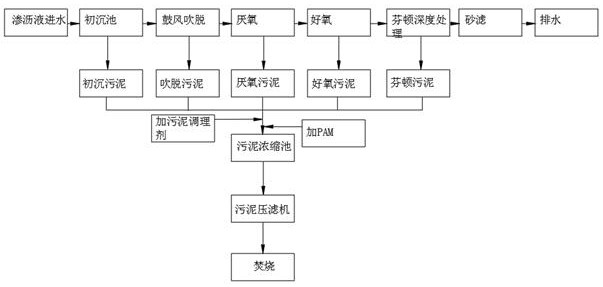

[0045] The leachate of a waste-to-energy plant supporting a mega city is treated by primary settling, air blowing, anaerobic digestion, aerobic biochemistry, and Fenton, and the sludge before entering the sludge concentration tank is treated at a rate of 0.01%. Add sludge conditioner in proportion, stir continuously for 90-150 minutes at 30-50°C, and stir at a speed of 60-80 rpm, then add PAM solution with a concentration of 0.1% at a ratio of 0.5% and stir continuously for 45-60 minutes , enter the sludge thickening tank after sedimentation, and then filter through the sludge filter press for 5 minutes. The experimental results are shown in Table 2 below:

[0046] Table 2: Dryness of leachable sludge after adding sludge conditioner

[0047] serial number formula Conditioning agent ratio (%) PAM ratio (%) Dryness of sludge after press filtration (%) blank 0.5 37 1 A 0.01 0.5 62 2 B 0.01 0.5 61 3 C 0.01 0.5 59

[0048] T...

Embodiment 3

[0050] The leachate of a waste-to-energy plant in a medium-sized city is subjected to primary settling, blown off, anaerobic digestion, aerobic biochemistry, and Fenton treatment, and the sludge before entering the sludge thickening tank is added at a ratio of 0.01%. Sludge conditioner, stir continuously for 90-150 minutes at 30-50°C, at a stirring speed of 60-80 rpm, then add 0.1% PAM solution in a proportion of 0.5% and continue stirring for 45-60 minutes, and precipitate Then enter the sludge thickening tank, and then filter through the sludge filter press for 5 minutes. The experimental results are shown in Table 3 below:

[0051] Table 3: Dryness of leachable sludge after adding sludge conditioner

[0052] serial number formula Conditioning agent ratio (%) PAM ratio (%) Dryness of sludge after press filtration (%) blank 0.5 38 1 A 0.01 0.5 62 2 B 0.01 0.5 63 3 C 0.01 0.5 62

[0053] The results in the above table s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com