Multi-crucible silicon carbide crystal synchronous growth method and equipment

A crucible silicon carbide, synchronous growth technology, applied in the direction of crystal growth, polycrystalline material growth, single crystal growth, etc., can solve the problems of slow growth speed, large crystal stress, expensive equipment, etc., to speed up growth speed and reduce internal stress. , the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

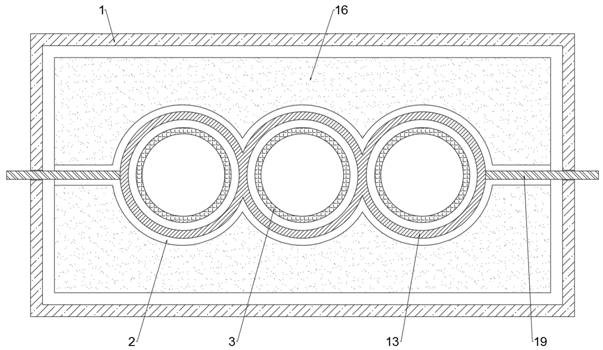

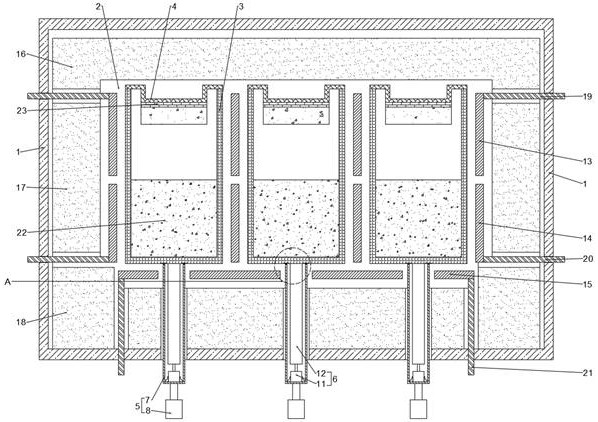

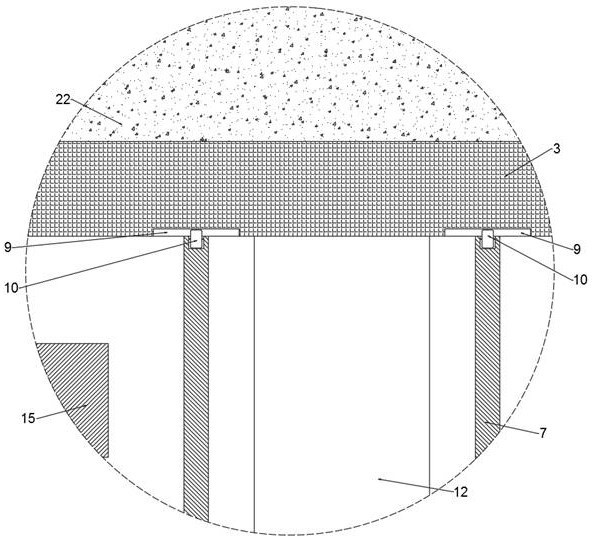

[0038] Such as figure 1 and figure 2As shown, a multi-crucible silicon carbide crystal synchronous growth equipment includes a cavity 1 and an insulation layer assembly arranged close to the inner wall of the cavity 1. The insulation layer assembly includes a first insulation layer that is close to the inner wall of the cavity 1 from top to bottom. 16. The second thermal insulation layer 17 and the third thermal insulation layer 18: the thermal insulation layer component divides the cavity 1 into several growth chambers 2, and each growth cavity 2 is provided with independent growth components; the independent growth components include Graphite crucible 3, the seed crystal tray 4 arranged on the top of graphite crucible 3, the heating device arranged on the periphery of graphite crucible 3, the driving assembly arranged at the bottom of graphite crucible 3, the heating device includes the first heating device which is arranged on the periphery of graphite crucible 3 Device 1...

Embodiment 2

[0044] Different from Embodiment 1, the horizontal cross-sectional shape of the growth cavity 2 in this embodiment is a regular octagon.

Embodiment 3

[0046] A multi-crucible method for synchronous growth of silicon carbide crystals, using the growth equipment described in Example 1 to perform synchronous growth of silicon carbide crystals, comprising the following steps:

[0047] S1. Preheating stage

[0048] After installing the graphite crucible 3, the driving components and the silicon carbide raw material, check the airtightness in the cavity 1, evacuate until the pressure in the cavity 1 is about 5 Pa, and further evacuate until the pressure in the cavity 1 is 10 Pa. -5 Around Pa, the pump body for vacuuming can use an existing molecular pump or a dry scroll pump. The pump body is connected to the cavity 1 through a vacuum pipeline (not shown in the figure), and the rotating motor fixed at the bottom of the synchronous growth equipment is turned on. , increase the power of the heating device to make the temperature in the cavity 1 reach 500°C, fill the cavity 1 with a mixture of nitrogen and argon, and after detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com