Ultra-light non-silicon PET release film and production process thereof

A production process and release film technology, applied in coatings, fireproof coatings, conductive coatings, etc., can solve the problems of precipitation and no silicon element, etc., and achieve the effect of simple ingredients, no coating spots, and no scratches on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

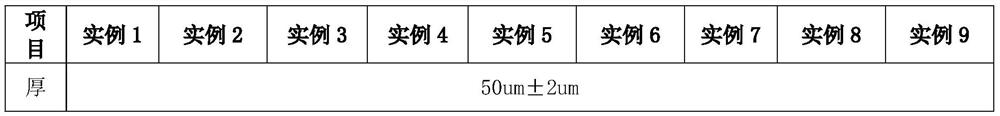

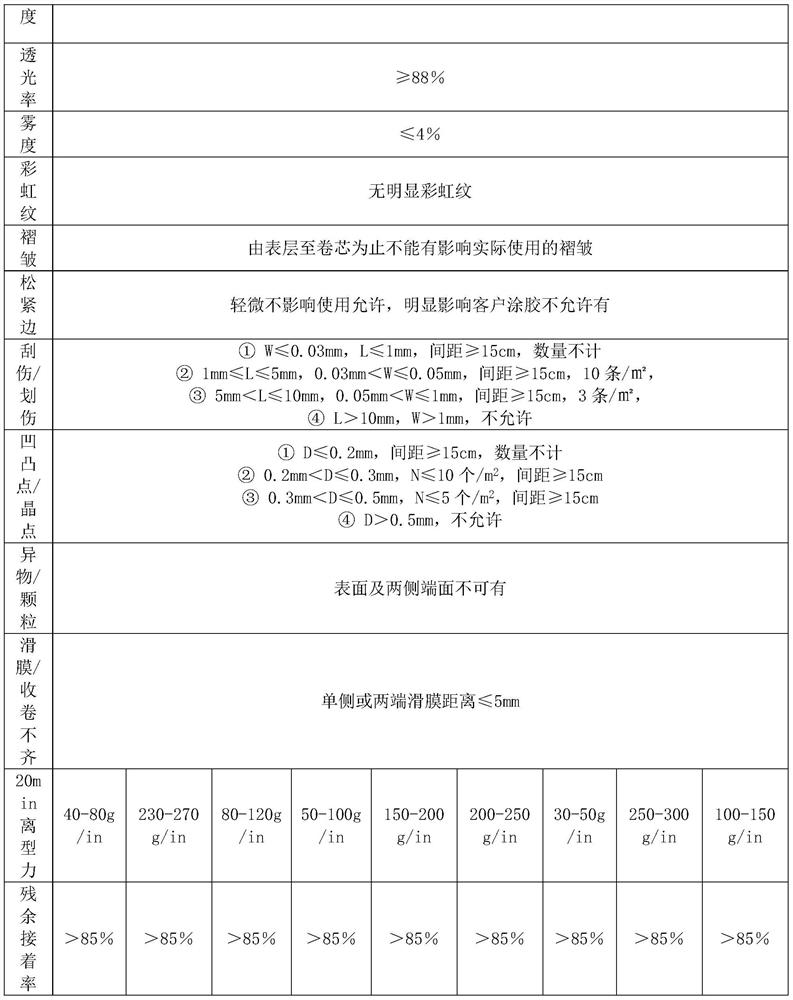

Examples

Embodiment 1

[0026] The invention provides an ultra-light non-silicon PET release film, comprising a PET release film base film, a coating, a treatment liquid a and a treatment liquid b, and before the PET release film base film is subjected to corona treatment, the treatment liquid is first used a After coating the PET release film base film evenly and drying it, soaking it with the treatment solution b, completing the pore-forming pretreatment of the PET release film base film, and then performing steam scraping on the PET release film base film Form uniform and dense micropores on the surface, and then perform corona treatment on the PET release film base film to enhance the adhesion of the PET release film base film surface, and then perform surface dust removal treatment on the PET release film base film to effectively reduce the original Floating dust on the surface of the film, and then apply the paint on the surface of the PET release film base film to form an ultra-light non-silico...

Embodiment 2

[0038] The difference from Example 1 is that the coating includes: 0.61% of nano-alumina, 0.32% of graphene, 1.77% of water-based polyurethane resin, 31% of polyacrylic resin with a solid content of 18%, and 22% of solid content by weight percentage. 9.0% polyacrylic resin, 0.61% polyisocyanate curing agent, 56.69% toluene; the calculation of the weight percentage of the treatment liquid a includes: 10% polyethylene glycol, 10% PET resin; the treatment liquid b is Ethanol and glycerol are prepared by mixing uniformly according to the volume ratio of 4:1.

Embodiment 3

[0040] All different from Examples 1-2, the coating includes: 0.58% of nano-alumina, 0.29% of graphene, 1.74% of water-based polyurethane resin, 29% of polyacrylic resin with a solid content of 18%, solid Content 22% polyacrylic resin 8.7%, polyisocyanate curing agent 0.58%, toluene 59.11%; The weight percent calculation of described treatment liquid a comprises: the PET resin of 8% polyethylene glycol, 92%; Described treatment Liquid b is prepared by mixing ethanol and glycerol in a volume ratio of 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com