GH4169 high-temperature alloy cast ingot forming method

A GH4169, high-temperature alloy technology, applied in the field of high-temperature alloys, can solve the problems of reducing the recrystallization ability of the alloy, serious dendrite segregation, and unfavorable alloy blanking performance, and achieves low blanking deformation activation energy, low segregation coefficient, and superiority. The effect of blanking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Each chemical composition of GH4169 superalloy is: 52.5Ni-19.0Cr-5.13Nb-3.05Mo-0.9Ti-0.5Al-0.05C-18.87Fe (wt%),

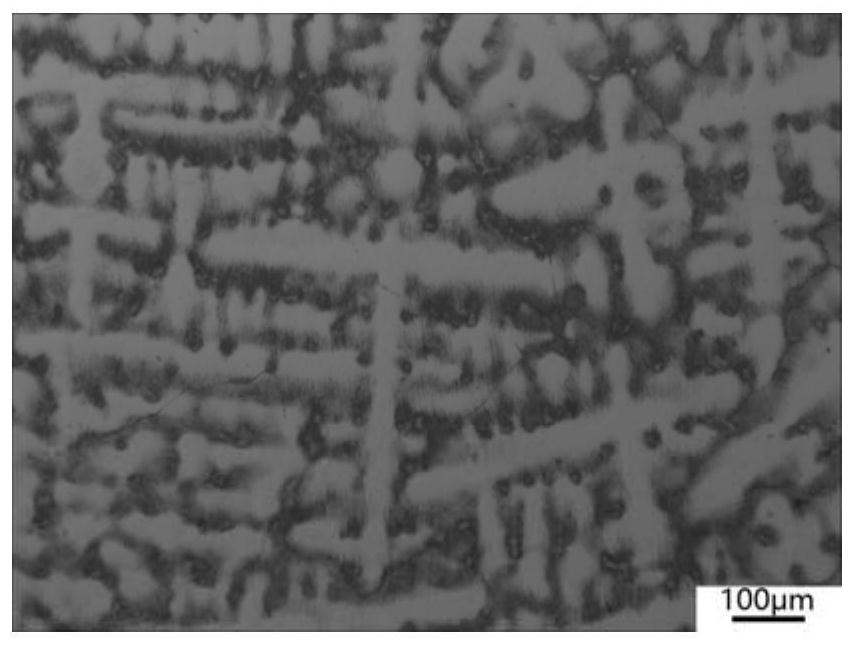

[0042] The tissue shape under the light microscope of the GH4169 alloy prepared by using the method of the present invention (laser process parameters of forming: power is 285W, scanning speed is 960mm / s, scanning distance is 80 μm, layer thickness is 40 μm, interlayer rotation angle is 17°) appearance, such as figure 2 As shown, the wavy lines are the morphology of the molten pool boundary left by laser melting metal powder, and the grains grow across the molten pool boundary, and the growth direction is consistent with the heat flow direction during solidification.

[0043] The mass fractions of elements in dendrites and interdendrites of additively manufactured GH4169 alloy were measured using EDS analysis, and the results are listed in Table 1. It can be found that there is segregation of Nb element on the dendrite, and the segregation coefficient of N...

Embodiment 2

[0057] Each chemical composition of GH4169 superalloy is: 52.5Ni-19.0Cr-5.10Nb-3.05Mo-0.9Ti-0.5Al-0.05C-18.87Fe (wt%),

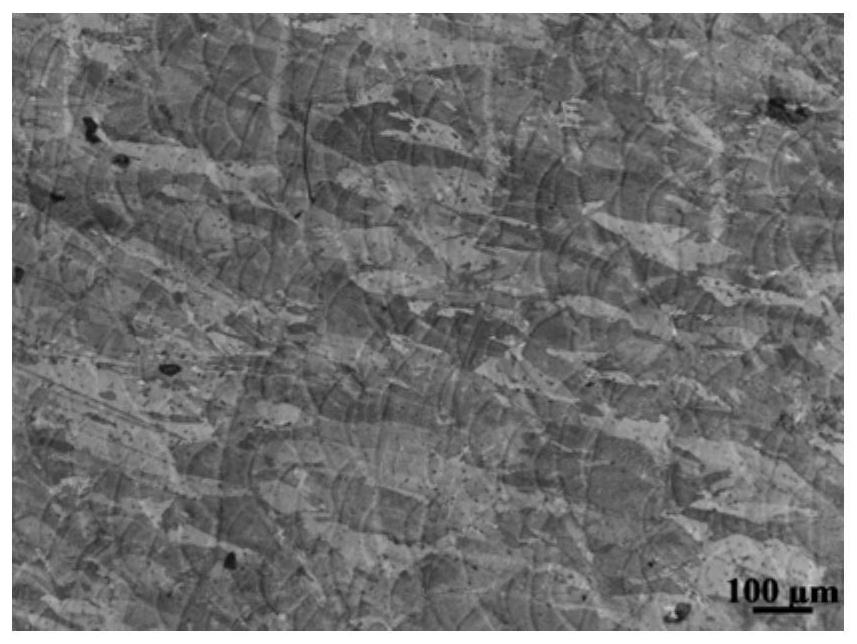

[0058] The GH4169 alloy microstructure prepared using the preparation process additive manufacturing method of the present invention (laser process parameters of forming: power is 285W, scanning speed is 970mm / s, scanning distance is 80 μm, layer thickness is 40 μm, and interlayer rotation angle is 20°) The appearance presents a wavy texture, which is the boundary morphology of the molten pool left by laser melting metal powder. The grains grow across the boundary of the molten pool, and their growth direction is consistent with the direction of heat flow during solidification.

[0059] The additively manufactured GH4169 alloy was directly billeted, the test temperature was 1050°C, and the strain rate was 5s -1 , the amount of deformation is 50%, the deformation of the sample after the test is uniform, and there is no crack after deformation. The GH4169 all...

Embodiment 3

[0061] Each chemical composition of GH4169 superalloy is: 52.5Ni-19.0Cr-4.75Nb-3.05Mo-0.9Ti-0.5Al-0.05C-18.87Fe (wt%),

[0062] The GH4169 alloy microstructure prepared using the preparation process additive manufacturing method of the present invention (laser process parameters of forming: power is 285W, scanning speed is 955mm / s, scanning distance is 81 μm, layer thickness is 39 μm, and interlayer rotation angle is 25°) The appearance presents a wavy texture, which is the boundary morphology of the molten pool left by laser melting metal powder. The grains grow across the boundary of the molten pool, and their growth direction is consistent with the direction of heat flow during solidification.

[0063] The additively manufactured GH4169 alloy was directly billeted, the test temperature was 1000°C, and the strain rate was 6s -1 , the amount of deformation is 60%, the deformation of the sample after the test is uniform, and there is no crack after deformation. The GH4169 all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com