Gallnut processing grinding device with filtering structure

A technology of filtering structure and grinding device, which is applied in the direction of making medicine into special physical or taking form, filtering screen, drying gas arrangement, etc. To ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

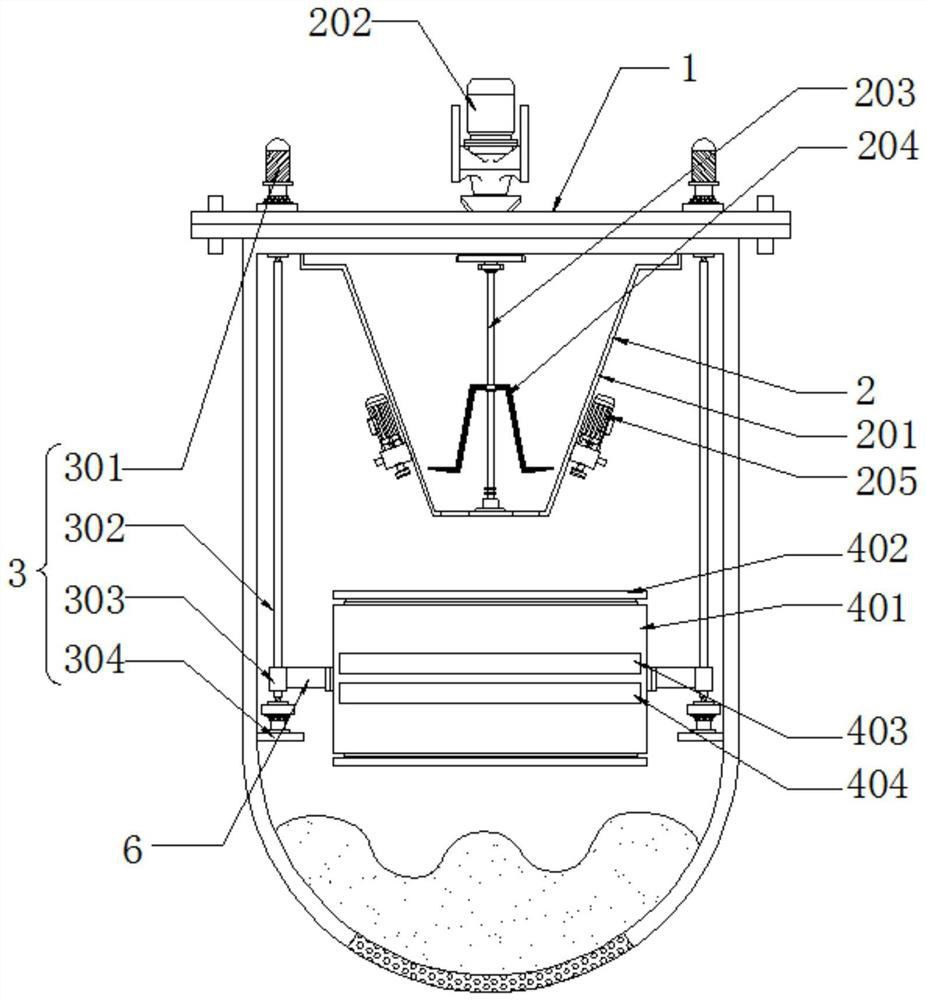

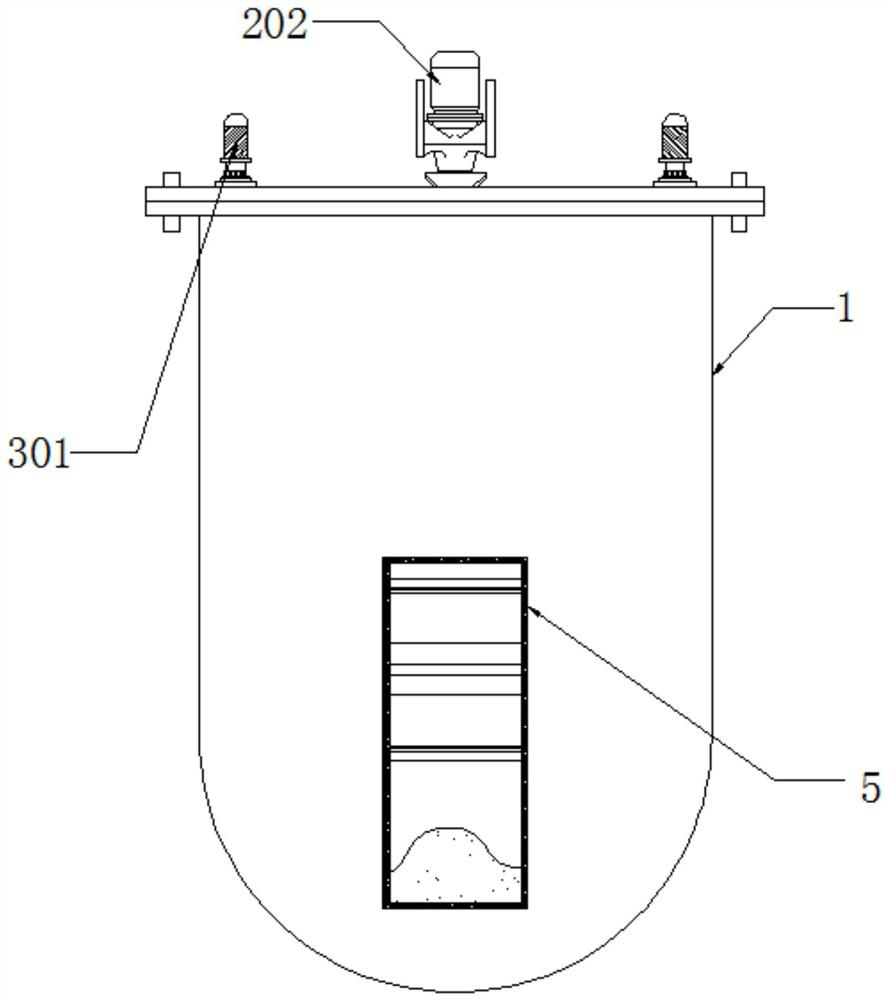

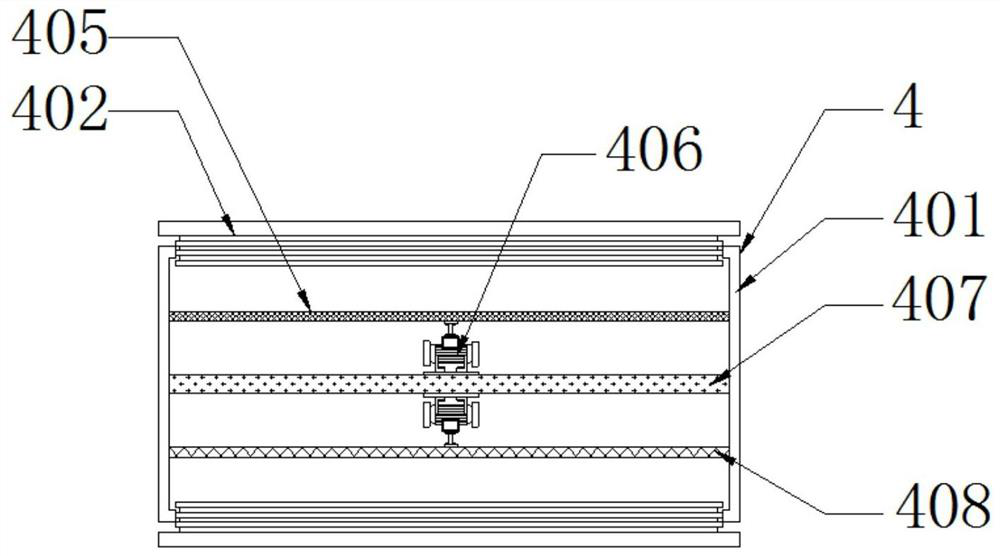

[0020] Such as Figure 1-2 As shown, a grinding device with a filter structure for gallnut processing includes a main tank body 1 and a filter assembly 4. A moving assembly 3 for moving the placement position is arranged on the upper left side of the main tank body 1. The moving assembly 3 includes a motor 301, screw mandrel 302, connecting block 303 and bearing seat 304, and the output end of motor 301 is connected with screw mandrel 302 through main tank body 1, and the outside of screw mandrel 302 is arranged with connecting block 303, and the bottom of screw mandrel 302 is connected by transmission There is a bearing seat 304, and a rotating shaft 6 is arranged on the right side of the connecting block 303. The connecting block 303 forms a transmission connection with the motor 301 through a screw rod 302, and the connecting block 303 and the rotating shaft 6 are arranged symmetrically with respect to the vertical central axis of the housing 401. Two, the housing 401 forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com