Method for observing crack initiation and expansion of hydraulic fracture by using confocal microscope

A technology of confocal microscope and hydraulic fracture, which is used in the application of repetitive force/pulsation force to test the strength of materials, instruments, measuring devices, etc., which can solve the problem that the confocal microscope has not been popularized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

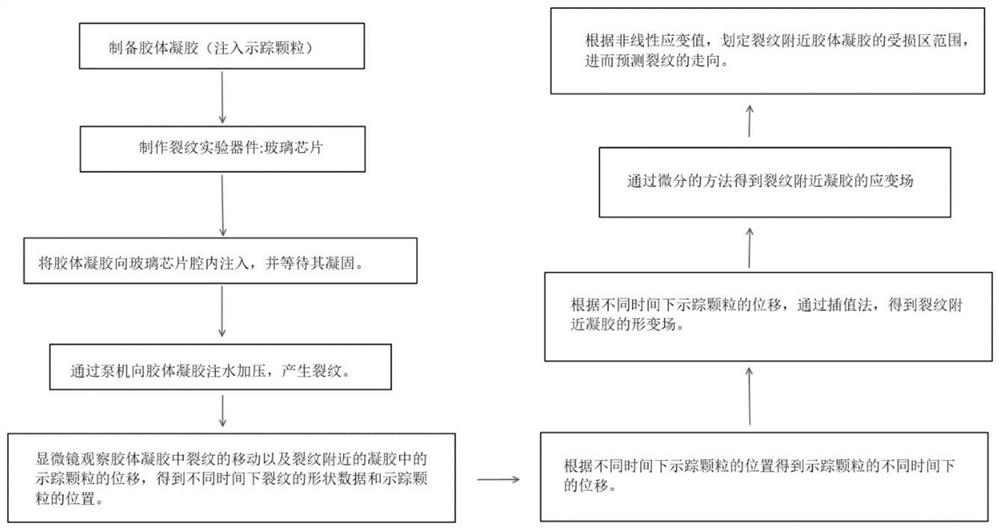

[0051] In the present invention, the preparation method of the colloidal gel preferably comprises the following steps:

[0052] Mix silica gel, urea and water to obtain silica gel-urea reagent;

[0053] The urease aqueous solution is mixed with the silica gel-urea reagent to obtain the colloidal gel.

[0054] In the present invention, before mixing the urease aqueous solution and the silica gel-urea reagent, it is preferred to further include defoaming. The present invention does not specifically limit the defoaming operation, and the defoaming operation well known to those skilled in the art can be used.

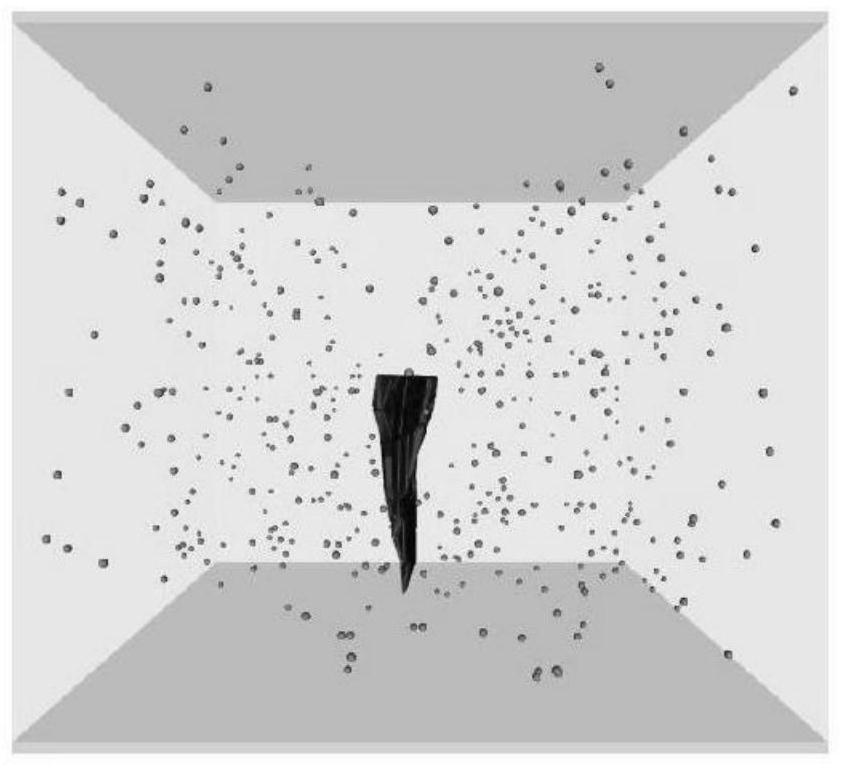

[0055] In the present invention, the sample to be tested preferably further includes tracer particles. In the present invention, the average particle diameter of the tracer particles is preferably 1.0 μm; the added amount of the tracer particles is preferably 2×10 of the volume of the sample to be tested. -6 %~2×10 -7 %. In a specific embodiment of the present inventio...

Embodiment 1

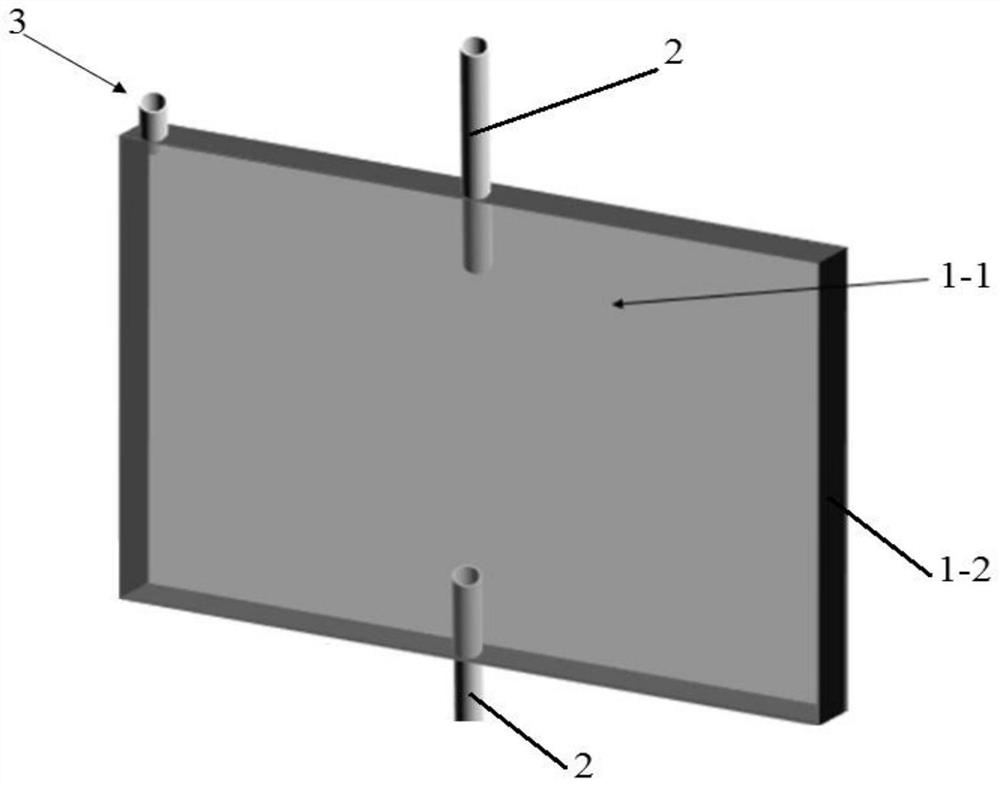

[0075] Such as figure 1 In the hydraulic fracture generating device shown, the sampling pipe 3 and the water inlet pipe 2 are both polyethylene pipes with an inner diameter of 0.034 inches and an outer diameter of 0.052 inches. The gap between the two glass sheets 1-1 is 2.0mm; the size of the two transparent glass sheets is 5cm*7.5cm*1.0mm.

[0076] To prepare colloidal gels:

[0077] The volume fraction of silicon dioxide in the colloidal gel is 7.5%, and the preparation method of the colloidal gel may further comprise the steps:

[0078] Configure 4mol / L urea solution for standby.

[0079] First add 2.5mL of urea solution with a concentration of 4mol / L to a 10mL test tube, add 3.75mL of a silica suspension with a mass fraction of 40%, add 3.75mL of distilled water, and mix well; add solidified colloid gel volume 2 ×10 -6 % of amine-modified polystyrene balls with an average particle size of about 1 μm.

[0080] Prepare another test tube, add 10 mg of urease, add 0.1 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com