Casting temperature curve measuring device

A technology of temperature curve and measuring device, which is applied in the direction of household refrigeration equipment, household appliances, material thermal development, etc., can solve the problem of difficult temperature of cylindrical castings, and achieves improved thermal insulation effect, strong stability, and interference between errors and external factors. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

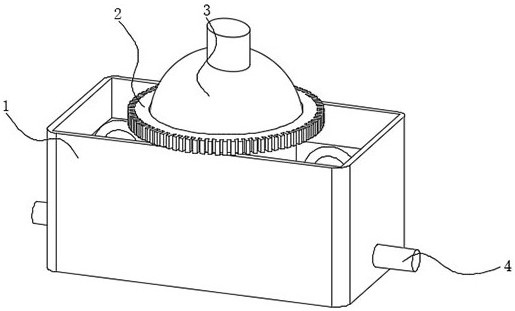

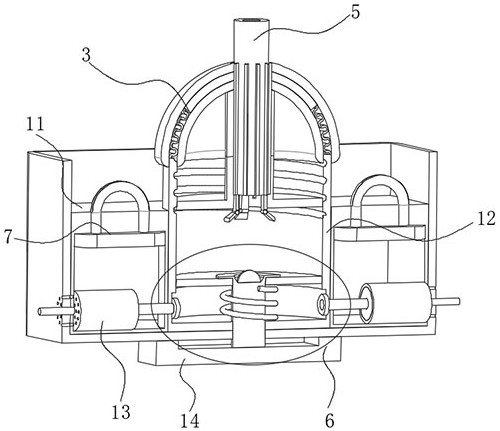

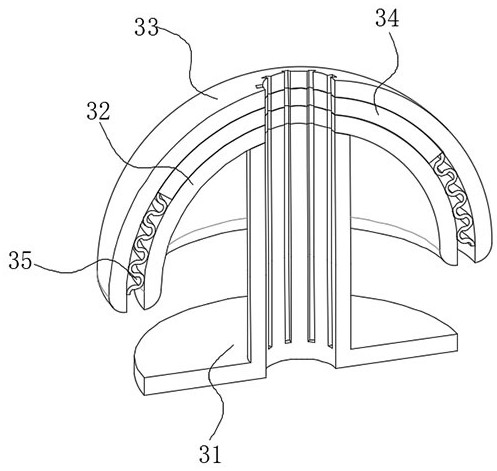

[0031] use Figure 1-Figure 6 A casting temperature curve measuring device according to an embodiment of the present invention is described as follows.

[0032] Such as Figure 1-Figure 6 As shown, a casting temperature curve measuring device of the present invention includes a temperature measuring box 1, a heat insulating sleeve 3 is slidably connected to the inner axis of the temperature measuring box 1, and an external frosting is fixedly connected to the upper part of the outer surface of the heat insulating sleeve 3. Ring 2, the two sides of the outer surface of the temperature measuring box 1 are symmetrically provided with drill holes, and the two sides of the outer surface of the temperature measuring box 1 are slidably connected with the external wire 4 through the drill holes, and one end of the external wire 4 extends to the inside of the temperature measuring box 1 .

[0033] The temperature measuring box 1 includes a sliding partition 11, and both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com