Preparation method of 1, 4-butanediol diglycidyl ether

A technology of diglycidyl ether and butanediol, which is applied in ether preparation, alkylene oxide preparation ether, organic chemistry and other directions, can solve the problem of high hydrolysis chlorine, achieve low hydrolysis chlorine, reduce TOC, and solve the effect of high organic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

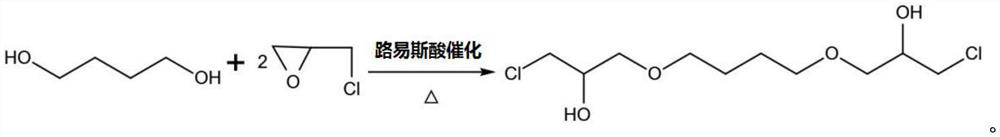

[0025] The invention provides a kind of preparation method of 1,4-butanediol diglycidyl ether, comprising the following steps:

[0026] Mix 1,4-butanediol, Lewis acid catalyst, epichlorohydrin and a water-immiscible solvent for etherification and ring-opening reaction to obtain chlorohydrin ether;

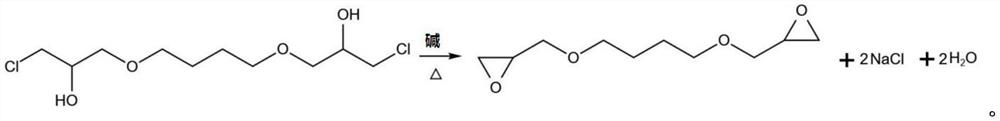

[0027] Mix the chlorohydrin ether with a water-immiscible solvent, add a main reaction catalyst, and dropwise add an aqueous alkali solution to carry out negative pressure closed-loop reflux dehydration to obtain 1,4-butanediol diglycidyl ether;

[0028] In the step-by-step dropwise addition of alkali aqueous solution to carry out negative-pressure closed-loop reflux dehydration, after each stage of dropwise addition of alkali aqueous solution, a section of negative-pressure closed-loop reflux dehydration is performed.

[0029] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art...

Embodiment 1

[0049] Add 160g of 1,4-butanediol, 160g of toluene and 2.5g of tin tetrachloride into a 2L reaction flask and stir evenly. After the temperature rises to 60°C, add 380g of epichlorohydrin dropwise for 2 hours. , heat up to 70°C and keep the ring-opening reaction for 4 hours to obtain a chlorohydrin ether solution; add 480g toluene and 0.8g polyethylene glycol 400 to the chlorohydrin ether solution, cool down to 42°C and add 85g dropwise at a uniform speed for the first time to a concentration of 50wt % NaOH solution, the first drop time is 0.5h, under the conditions of 42°C and 10Torr, the first negative pressure closed-loop reflux dehydration is 0.5h, and then the second dropwise addition of 85g of NaOH solution with a concentration of 50wt% under the condition of 42°C , the second dropping time is 1h, under the condition of 42°C and 10Torr, the second negative pressure closed-loop reflux dehydration is 0.5h, under the condition of 42°C, 85g of NaOH solution with a concentrati...

Embodiment 2

[0051] Add 160g of 1,4-butanediol, 480g of toluene and 2.5g of boron trifluoride into a 2L reaction flask and stir evenly. After the temperature rises to 60°C, add 380g of epichlorohydrin dropwise for 1 hour. , heat up to 70°C and keep the ring-opening reaction for 5 hours to obtain a chlorohydrin ether solution; add 160g of toluene and 1.6g of polyethylene glycol 400 to the chlorohydrin ether solution, cool down to 42°C and then add 90g dropwise at a uniform speed for the first time to a concentration of 50wt % NaOH solution, the first drop time is 0.5h, under the condition of 42°C and 10Torr, the first negative pressure closed-loop reflux dehydration is 0.5h, and then the second dropwise addition of 90g of NaOH solution with a concentration of 50wt% under the condition of 42°C , the second dropping time is 1h, under the condition of 42°C and 10Torr, the second negative pressure closed-loop reflux dehydration is 0.5h, and the third dropwise adding 90g of NaOH solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com