Selective laser melting and laser shock strengthening composite additive manufacturing equipment and method

A technology of laser selective melting and laser shock strengthening, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement. Laser forming range, prolonging action time, increasing the effect of peak pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

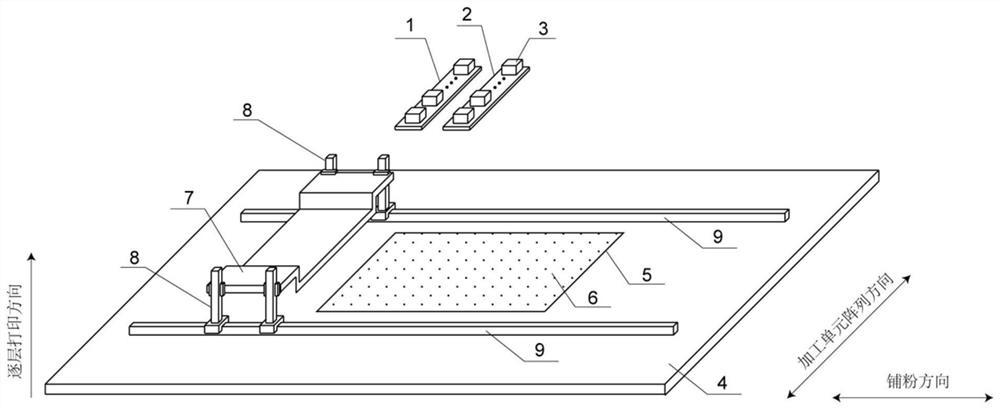

Embodiment 1

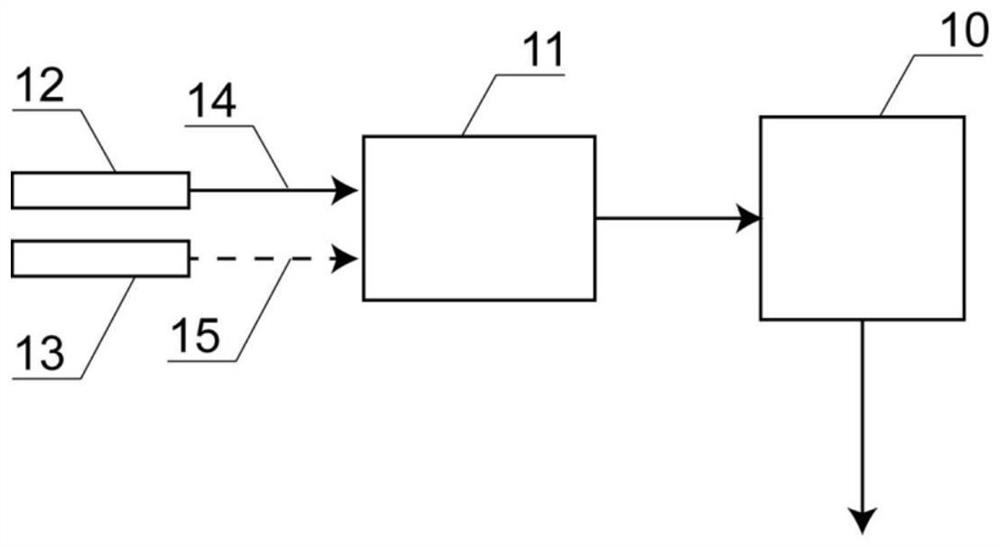

[0055] A multi-laser selective melting and impact strengthening composite additive manufacturing equipment, which includes a set of processing components, and the first processing unit array 1 and the second processing unit array 2 each include four processing units 3 arrayed along the front and rear directions; The first collimating mirror 12 of each processing unit 3 is externally connected to a continuous fiber laser with a wavelength of 1070nm and a maximum power of 4000W, and the second collimating mirror 13 is externally connected to a wavelength of 1064nm, a single pulse energy of 0.1-50J, and a pulse width of 1- 30ns nanosecond pulsed laser with a frequency of 0.5-50Hz.

[0056] Relying on the equipment, the present invention further provides a multi-laser selective melting and multi-laser shock strengthening composite additive manufacturing method for TC4 titanium alloy parts. Each layer of the part needs to be processed by LSP. The steps include: :

[0057] S1 as ...

Embodiment 2

[0074]A multi-laser selective melting and impact strengthening composite additive manufacturing equipment, which includes a set of processing components, and the first processing unit array 1 and the second processing unit array 2 both include 8 processing units 3 arrayed along the front and rear directions; The first collimating mirror 12 of each processing unit 3 is externally connected to a continuous fiber laser with a wavelength of 1064nm and a maximum power of 500W, and the second collimating mirror 13 is externally connected to a wavelength of 532nm, a single pulse energy of 0.1-50J, and a pulse width of 1- 30ns nanosecond pulsed laser with a frequency of 0.5-50Hz.

[0075] Relying on the above-mentioned equipment, the present invention further provides a multi-laser selective melting and multi-laser shock strengthening composite additive manufacturing method for a GH4169 nickel-based superalloy part. include:

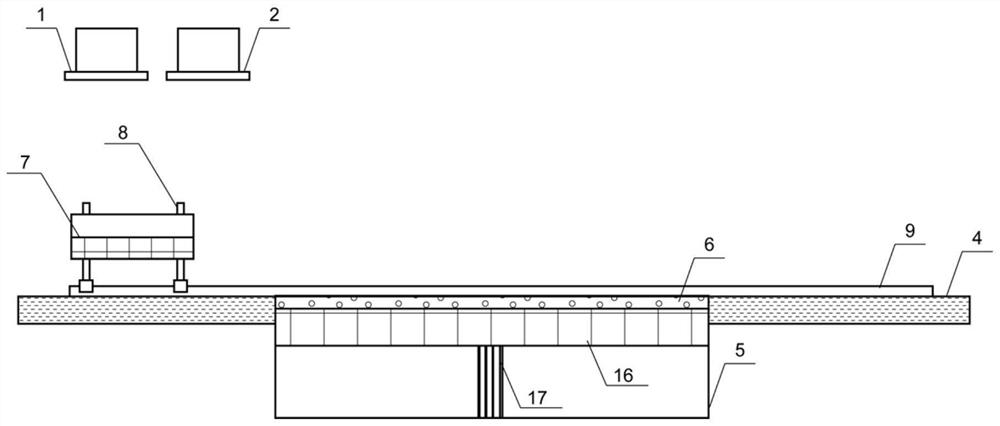

[0076] S1 as image 3 As shown, the base plate 16 in the...

Embodiment 3

[0091] A multi-laser selective melting and impact strengthening composite additive manufacturing equipment, which includes a set of processing components, and the first processing unit array 1 and the second processing unit array 2 both include 8 processing units 3 arrayed along the front and rear directions; The first collimating mirror 12 of each processing unit 3 is externally connected to a continuous fiber laser with a wavelength of 1064nm and a maximum power of 500W, and the second collimating mirror 13 is externally connected to a wavelength of 532nm, a single pulse energy of 0.1-50J, and a pulse width of 1- 30ns nanosecond pulsed laser with a frequency of 0.5-50Hz.

[0092] Relying on the above-mentioned equipment, the present invention further provides a multi-laser selective melting and multi-laser shock strengthening composite additive manufacturing method for 304 austenitic stainless steel parts. include:

[0093] S1 as image 3 As shown, the base plate 16 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com