High-content sodium trifluoromethanesulfinate refining equipment and high-content sodium trifluoromethanesulfinate manufacturing method

A technology of sodium trifluoromethyl sulfinate and content, which is applied in the direction of separation methods, chemical instruments and methods, mixers with rotating stirring devices, etc., and can solve the problems that are not conducive to improving product quality and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

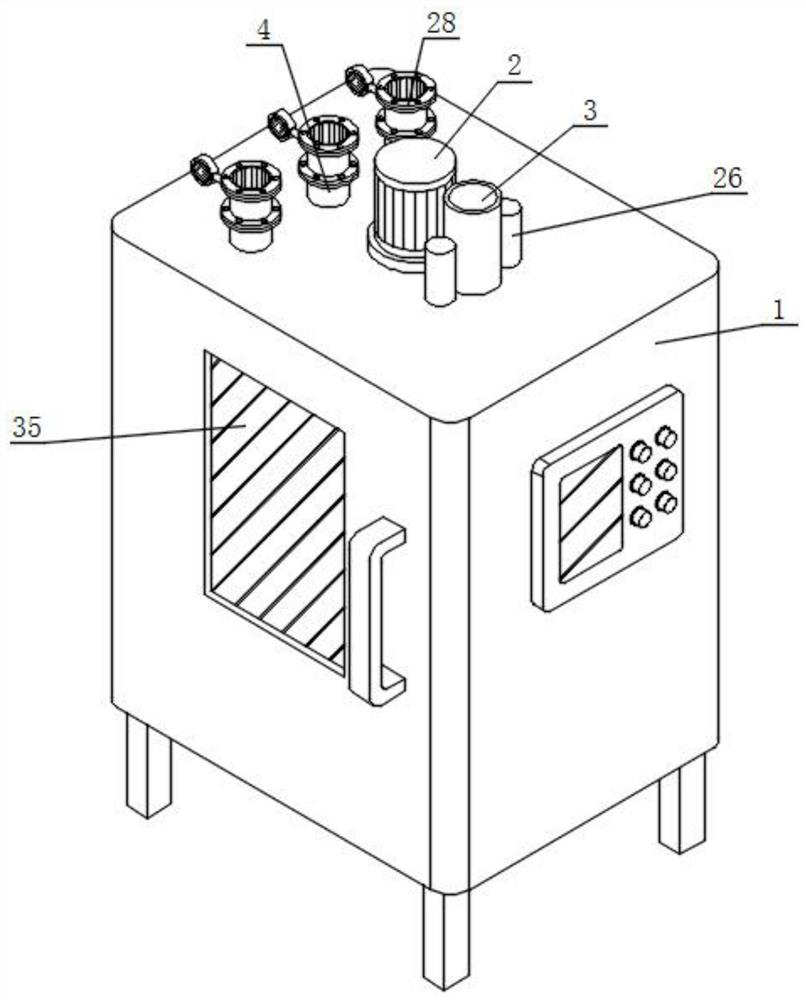

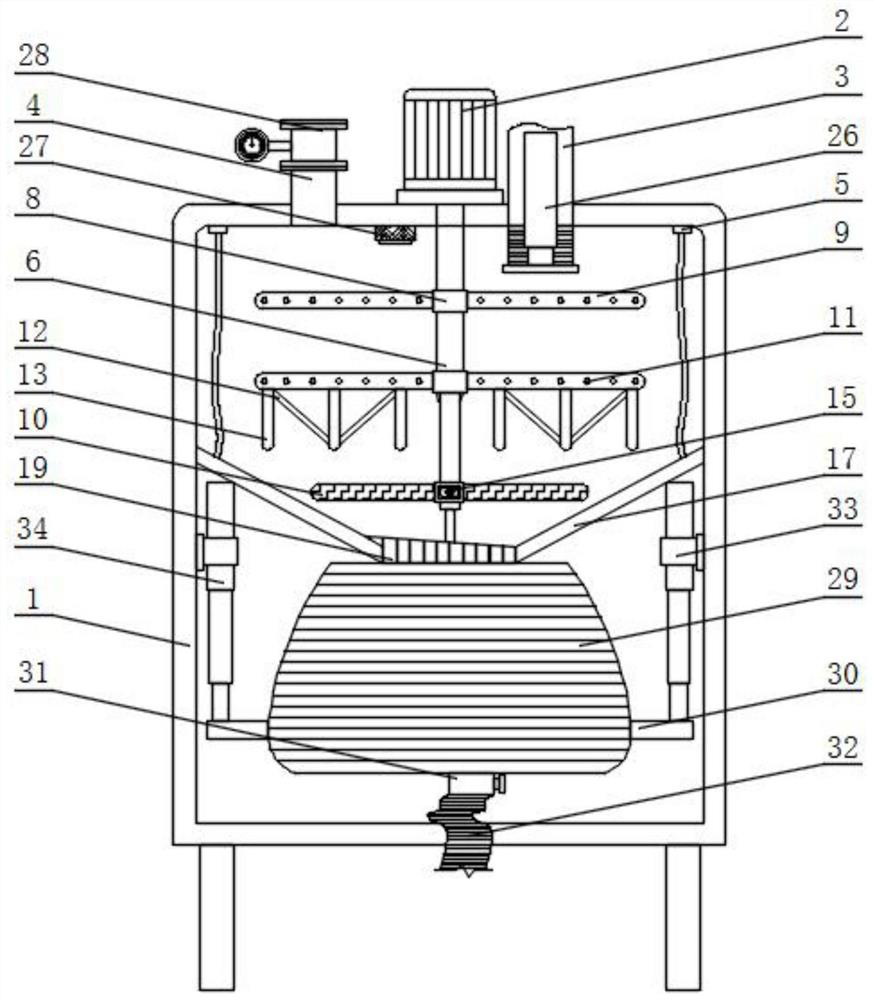

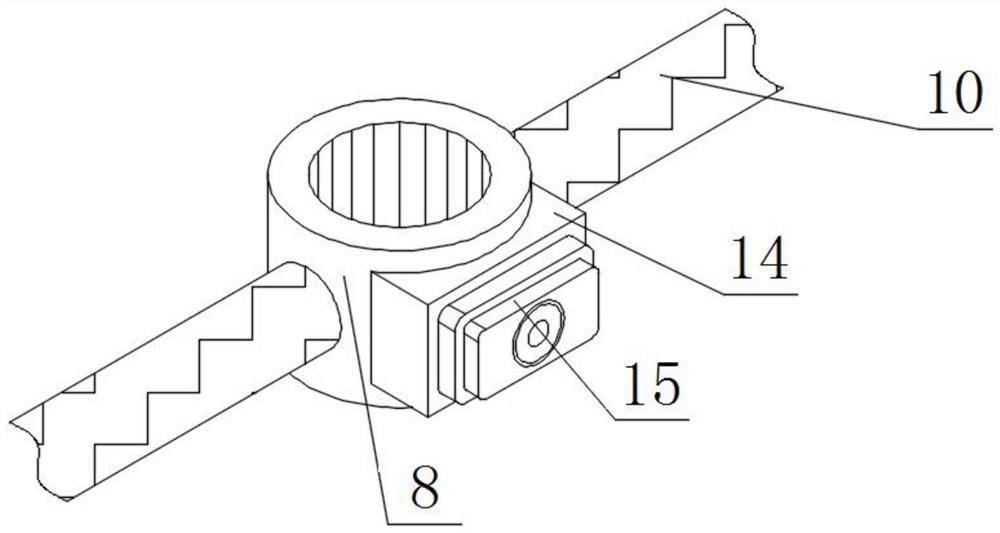

[0048] Such as figure 2 , image 3 As shown, a kind of sodium trifluoromethyl sulfinate refining equipment with high content includes equipment box 1, servo motor 2, suction pipe 3, feed pipe 4 and fixed block 5, and the top of equipment box 1 is installed with servo Motor 2, suction pipe 3 is installed on the top of equipment box 1, and suction pipe 3 is located on one side of servo motor 2;

[0049] Specifically, the equipment box 1 provides an activity space for the device to perform various operations. When the servo motor 2 is started, the shaft installed at the output end can drive the drum 6 to rotate clockwise or counterclockwise. The suction pipe 3 is used to It is connected with an external dust collection device, and then when the dust collection device is started, the air at the tail end of the suction pipe 3 can be pumped into the interior of the dust collection device.

[0050] The top of the servo motor 2 is equipped with multiple sets of feeding pipes 4 arra...

Embodiment 2

[0057] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the bottoms of the four groups of fixed blocks 5 are equipped with connecting ropes 16, and the bottoms of the connecting ropes 16 are equipped with inclined frames 17, the bottom wall of the inclined frame 17 is provided with notches 18, and the inner wall of the notches 18 is equipped with filter plates 19 , the bottom of the movable cylinder 7 is provided with a fitting groove, the top of the filter plate 19 is equipped with a connecting column 20, and the top of the connecting column 20 extends into the inside of the fitting groove, and the top of the connecting column 20 is equipped with a fitting circular plate 21, And the outer wall of the fitting circular plate 21 is attached to the inside of the fitting groove.

[0058] Specifically, the connecting rope 16 is used to connect the fixed block 5 and the tilting frame 17. When the comprehensive length of the electric telescopic rod 22...

Embodiment 3

[0066] Such as figure 1 and figure 2 As shown, a distance sensor 27 is installed on the top wall of the equipment box 1 , and a flow meter 28 is installed on the tops of multiple feed pipes 4 .

[0067] Specifically, the distance sensor 27 can monitor the distance between itself and the top surface of the solvent I below in real time, and when the distance reaches the set value, the external conveying equipment can be turned off, and the flow meter 28 can monitor the flow of the material passing through its pipeline in real time. flow value.

[0068] The inner walls of both sides of the equipment box 1 are equipped with fixing parts 33, and the tops of the two groups of fixing parts 33 are installed with multiple electric extension rods 34, and the bottoms of the two groups of multi-section electric extension rods 34 are connected with the two groups of horizontal plates 30 respectively. Fitted top.

[0069] Specifically, the fixing part 33 is used to install the multi-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com