Acerola cherry tabletted candies and preparation method thereof

A technology for tableting candies and acerola cherries, which is applied in confectionary, confectionery industry, and food ingredients as taste improvers, etc. It can solve the problems of fragmentation and collapse, improve hardness and friability, and be easily accepted by the market , The effect of hardness stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

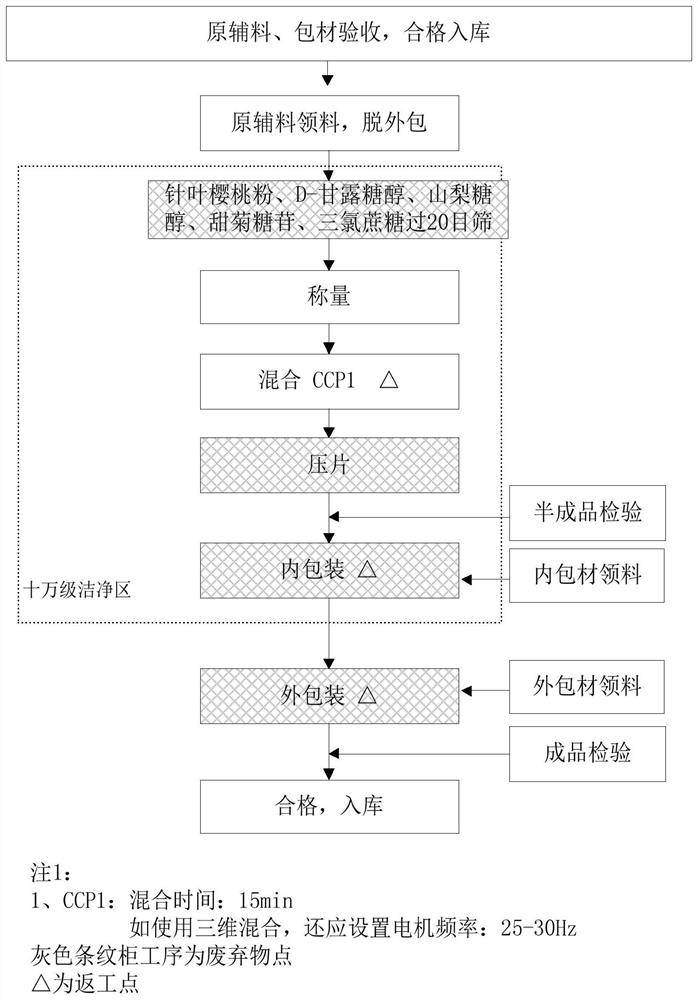

Method used

Image

Examples

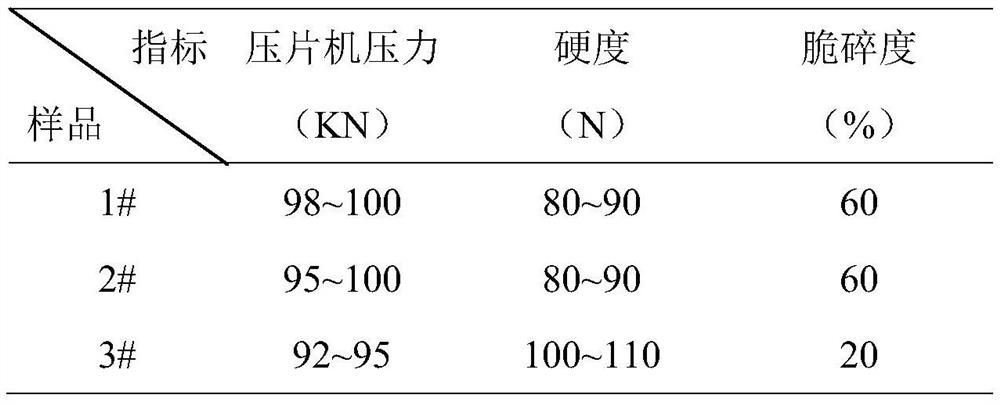

Embodiment 1

[0052] According to the mass percentage measure, the formula group of the tablets is: 33.2% of the coniferous cherry powder, the sorbitol 28.6, microcrystalline cellulose 15%, D-mannitol 1%, stevulidin 1%, blueberry powder 20%, 0.2% of Trichlorosose and 1% of stearate;

[0053] Further, the coniferous cherry tablet candy is obtained by the following preparation steps:

[0054] a) Sintering: the coniferous cherry powder, blueberry powder, sorbitol, D-mannocyanol all 20 mesh sieve, and mix the material is uniform;

[0055] b) Premix: Trichloroside, the blueberry fruit powder is premixed for 5 min after drying machine, resulting in a mixture A;

[0056] c) Total mixing: sorbitol, coniferous cherry powder, mixture A, D-mannool, microcrystalline, blueberry powder in turn into the mixer, and finally add stearate calcium in a throwing manner. It is evenly dispersed, with a total mixing time of 15 min;

[0057] d) Tablet: 20 rpm of pressurizing machine speed / min to get a tablet candy as...

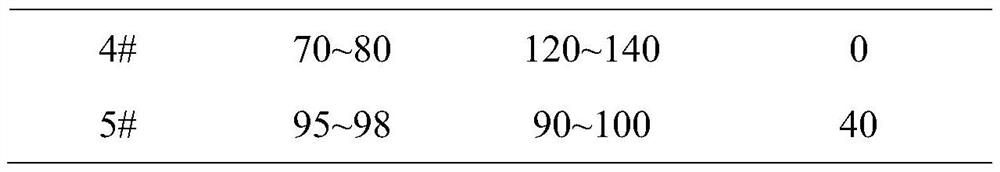

Embodiment 2

[0059] According to the mass percentage, the formula group of the tablets is: 30% of the coniferous cherry powder, 28.6% sorbitol, 20% microcrystalline cellulose, 5% D-mannocyanol, 0.3% of stevulin, 15% blueberry powder 0.1% and 1% magnesium stearate;

[0060] Further, the preparation step of the coniferous cherry tablet candy is:

[0061] a) Sintering: the coniferous cherry powder, blueberry powder, sorbitol, D-mannocyanol all 20 mesh sieve, and mix the material is uniform;

[0062] b) Premix: Trichloroside, the blueberry fruit powder is premixed for 8 min after dry mixing machine to obtain a mixture A;

[0063] c) Total mixed: sorbitol, coniferous cherry powder, mixture A, D-mannool, microcrystalline cellulose, blueberry powder in turn into the mixer, and finally add stearate in a throwing method, so that It is evenly dispersed, the total mixing time is 20 min;

[0064] d) Tablet: The pressurizing machine speed is 18 turns / min, and the tablet candy is obtained as 2 #.

Embodiment 3

[0066] According to the mass percentage, the recipe group of the tablets is: 30% of the coniferous cherry powder, 29.1% sorbitol, 5% microcrystalline cellulose, 5% D-mannocyanol, stevi glycoside 0.3%, Blueberry 15% 0.1% of Trichloro sucrose and 0.5% of magnesium stearate;

[0067] Further, the preparation step of the coniferous cherry tablet candy is:

[0068] a) Sintering: the coniferous cherry powder, blueberry powder, sorbitol, D-mannocyanol all 20 mesh sieve, and mix the material is uniform;

[0069] b) Premix: Trichloroside, the blueberry fruit powder is premixed for 8 min after dry mixing machine to obtain a mixture A;

[0070] c) Total mixed: sorbitol, coniferous cherry powder, mixture A, D-mannool, microcrystalline cellulose, blueberry powder in turn into the mixer, and finally add stearate in a throwing method, so that It is evenly dispersed, the total mixing time is 20 min;

[0071] d) Tablet: The pressurizing machine speed is 18 rpm, and the tablet candy is obtained as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com