Preparing method of nylon bonded Nd-Fe-B magnet

A NdFeB magnet technology is applied in the field of preparation of bonded NdFeB permanent magnet materials, which can solve the problems of low injection pressure and high nylon content, and achieve the effects of improving filling behavior, simple preparation method and reducing frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Surface modification treatment step: add 1g silane into a beaker equipped with 50ml ethanol to prepare 0.02g / ml silane ethanol solution, then add 200g of isotropic Nd-Fe-B magnetic powder, at this time the silane and magnetic powder The mass ratio is 0.5%. After stirring for 20 minutes, put it into an ultrasonic cleaner for vibration dispersion treatment for 2 hours, take it out and let it stand for 3 hours, and then dry it in an oven at a drying temperature of 60°C to obtain coupled magnetic powder;

[0020] (2) Molding step: take 1.5g nylon powder and 100g coupled magnetic powder and mix evenly. At this time, the mass ratio of nylon powder and coupled magnetic powder is 1.5%. Each time weigh the same amount of powder and put it into the mold. After the temperature rises to 180°C, carry out compression molding under a pressure of 600Mpa, hold the heat for 5 minutes, and then cool the mold to 50°C for demoulding to obtain a sample blank;

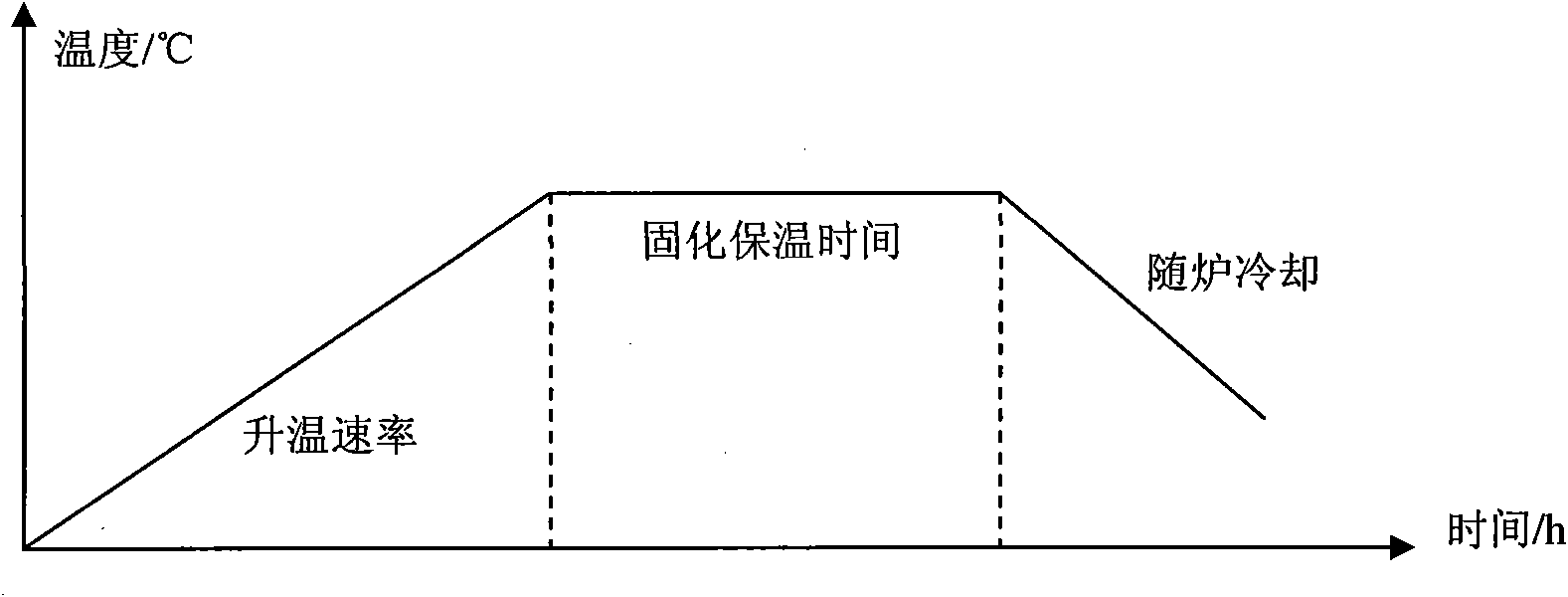

[0021] (3) Curing treatmen...

Embodiment 2

[0024] (1) Surface modification treatment step: 3g silane is added in the beaker that 120ml ethanol is housed to prepare the silane ethanol solution of 0.025g / ml, then add the isotropic Nd-Fe-B magnetic powder of 200g, now the silane and magnetic powder The mass ratio is 1.5%. After stirring for 30 minutes, put it into an ultrasonic cleaner for vibration dispersion treatment for 3 hours, take it out and let it stand for 5 hours, and then dry it in an oven at a drying temperature of 80°C to obtain coupled magnetic powder;

[0025] (2) Molding step: take 5.0g nylon powder and 100g coupled magnetic powder and mix evenly. At this time, the mass ratio of nylon powder to coupled magnetic powder is 5.0%. Each time weigh the same amount of powder and put it into the mold. After the temperature rises to 220°C, it is pressed and formed under a pressure of 1200Mpa, the heat preservation and pressure holding time is 10min, and then the mold is cooled to 60°C for demoulding to obtain a samp...

Embodiment 3

[0029] (1) Surface modification treatment step: 2g silane is added in the beaker that 90ml ethanol is housed to prepare the silane ethanol solution of 0.0222g / ml, then add the isotropic Nd-Fe-B magnetic powder of 200g, now the silane and magnetic powder The mass ratio is 1.0%. After stirring for 25 minutes, put it into an ultrasonic cleaner for vibration dispersion treatment for 2.5 hours, take it out and let it stand for 4 hours, and then dry it in an oven at a drying temperature of 70°C to obtain coupled magnetic powder;

[0030] (2) Molding step: take 4.0g nylon powder and 100g coupled magnetic powder and mix evenly. At this time, the mass ratio of nylon powder to coupled magnetic powder is 4.0%. Each time weigh the same amount of powder and put it into the mold. After the temperature rises to 200°C, carry out compression molding under a pressure of 1000Mpa, hold the heat for 8 minutes, and then cool the mold to 55°C for demoulding to obtain a sample blank;

[0031] (3) Cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com