A low-carbon anti-fatigue steel plate for wind power and its preparation method

An anti-fatigue and wind power technology, applied in the field of iron and steel metallurgy, can solve the problems of high strength, good weldability and anti-fatigue performance, low impact energy at the core of the steel plate, complex component selection, etc., and achieve low welding cracks. Sensitivity index, tissue homogeneity, effect of low carbon equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

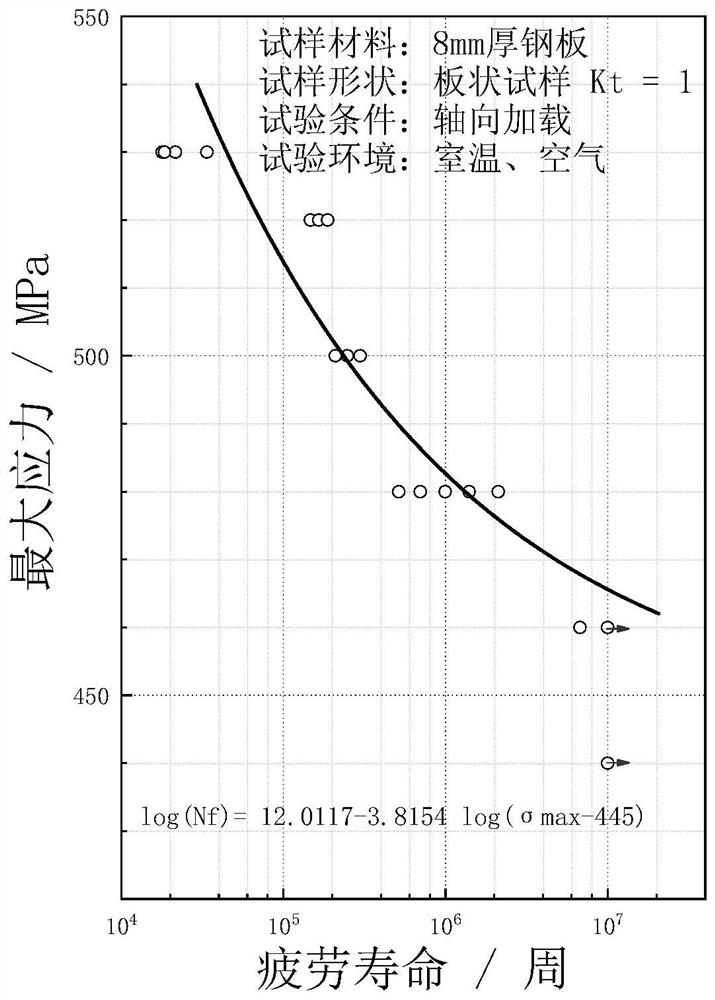

[0047] A low-carbon anti-fatigue steel plate for wind power, the chemical composition (wt.%) is C: 0.09%, Si: 0.25%, Mn: 1.53%, Nb: 0.022%, Al: 0.037%, Ti: 0.016%, Ni: 0.14%, V: 0.023%, Cr: 0.02%, N: 0.072%, P: 0.011, S: 0.001%, O: 0.0016%, CEV=0.37, PCM=0.19, and the rest are Fe and unavoidable impurities.

[0048] In the thermal process of the steel plate heat treatment process, the billet is heated at a temperature of 1188° C. and held for 54 minutes. In the TMCP process, the starting temperature of rolling is 1176°C, the total deformation of rough rolling is 65%, and the reduction in two passes after rough rolling is 27%, and the starting temperature of finish rolling is 895°C, and the reduction rate is 71%. In the subsequent cooling stage, the cooling rate was 8°C / s.

[0049] In the tempering heat treatment stage, the temperature is controlled at 477°C, and the holding time is 10 minutes.

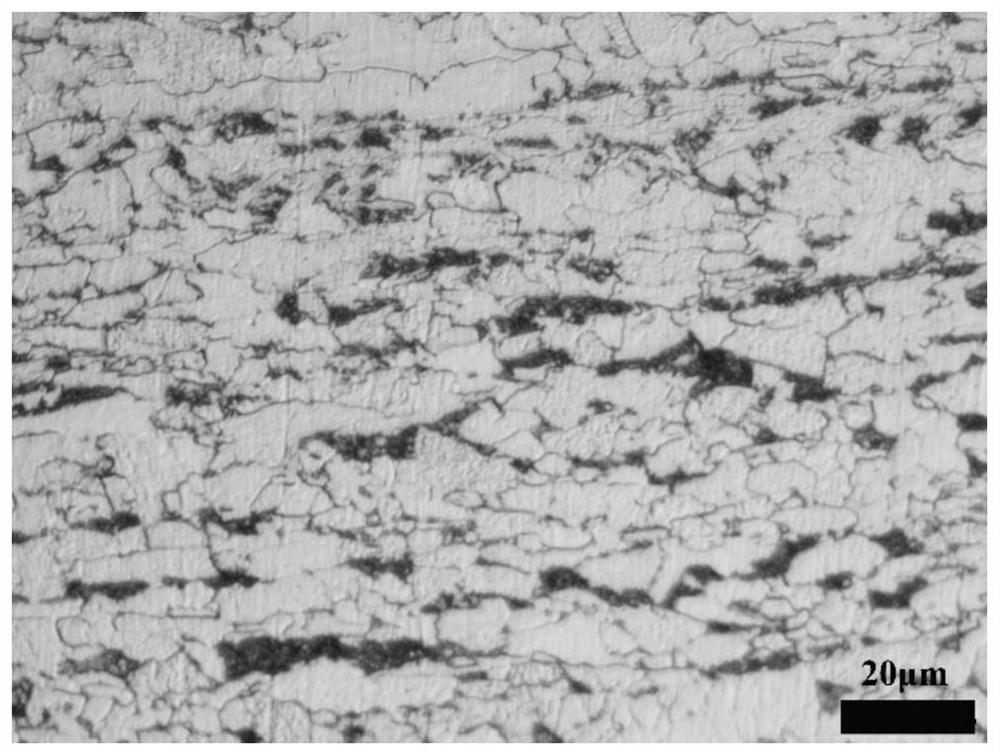

[0050] Such as figure 2 As shown, the average grain size of the steel for wind...

Embodiment 2

[0052] A low-carbon anti-fatigue steel plate for wind power, the chemical composition (wt.%) is C: 0.098%, Si: 0.27%, Mn: 1.55%, Nb: 0.025%, Al: 0.046%, Ti: 0.016%, Ni: 0.16%, V: 0.024%, Cr: 0.02%, N: 0.065%, P: 0.01, S: 0.004%, O: 0.0016%, CEV=0.38, PCM=0.19, and the rest are Fe and unavoidable impurities.

[0053] In the thermal process of the steel plate heat treatment process, the billet is heated at a temperature of 1188° C. and held for 55 minutes. In the TMCP process, the starting temperature of rolling is 1173°C, the reduction rate of rough rolling is 68%, and the reductions of the two passes after rough rolling are 25% and 26% respectively, the starting temperature of finishing rolling is 896°C, and the reduction rate is 71% , followed by a cooling stage with a cooling rate of 8°C / s.

[0054] In the tempering heat treatment stage, the temperature is controlled at 479°C, and the holding time is 10 minutes.

[0055] The average grain size of the steel for wind power i...

Embodiment 3

[0057] A low-carbon anti-fatigue steel plate for wind power, the chemical composition (wt.%) is C: 0.10%, Si: 0.30%, Mn: 1.50%, Nb: 0.026%, Al: 0.04%, Ti: 0.017%, Ni: 0.17%, V: 0.026%, Cr: 0.06%, N: 0.05%, P: 0.01, S: 0.003%, O: 0.0018%, CEV=0.36, PCM=0.19, and the rest are Fe and unavoidable impurities.

[0058] In the thermal process of the steel plate heat treatment process, the billet is heated at a temperature of 1168° C. and held for 65 minutes. In the TMCP process, the starting temperature of rolling is 1160°C, the reduction rate of rough rolling is 65%, and the reductions in the last two passes are 25% and 26% respectively, the starting temperature of finishing rolling is 890°C, and the reduction rate is 72%, and then In the cooling stage, the cooling rate is 10°C / s.

[0059] In the tempering heat treatment stage, the temperature is controlled at 482°C, and the holding time is 10 minutes.

[0060] The average grain size of the steel for wind power is 11 μm, composed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com