Preparation method and application of porous alginate membrane

A technology of alginate and sodium alginate, which is applied in the field of preparation of porous alginate membranes, can solve the problems of unsuitable large-scale processing, low efficiency of porous membrane-forming technology, poor mechanical properties of membranes, etc., and achieves good porous frame structure, The effect of improving hole forming efficiency and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

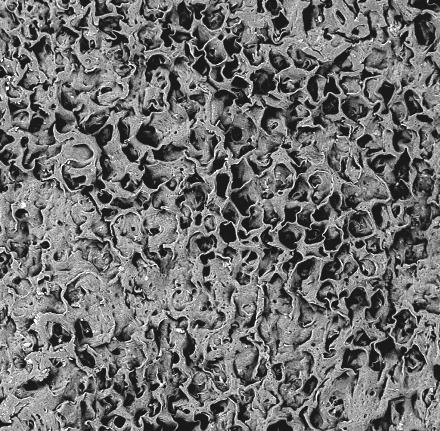

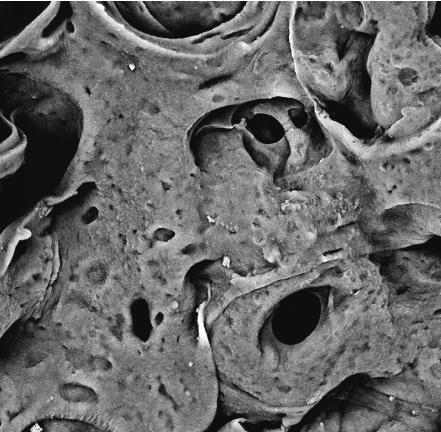

[0027] Dissolve 0.3g of sodium alginate in 10mL of pure water and let it stand for 12h for defoaming. Take 0.5mL of sodium alginate solution and pour it into a flat-bottomed sample dish, and spread it flat with a thickness of 0.5mm. Then put the sample dish into a freezer and freeze it at -80°C for 2 hours. In addition, to prepare a thawing coagulant, mix 94g of absolute ethanol, 5g of anhydrous calcium chloride, 0.5g of glycerin, and 0.5g of water, and stir to dissolve at room temperature. Then, 2.5 mL of thawing coagulant was injected into the frozen sodium alginate solution, and it was thawed and cross-linked and solidified at -20°C for 6 hours. Thereafter, the porous alginate membrane is taken out, rinsed with pure water, and air-dried at 20°C. The resulting porous alginate membrane has a thickness of about 0.5 mm, is soft and porous (see figure 1 with figure 2 ). from figure 1 It can be seen that the alginate membrane has high porosity and uniform distribution. mag...

Embodiment 2

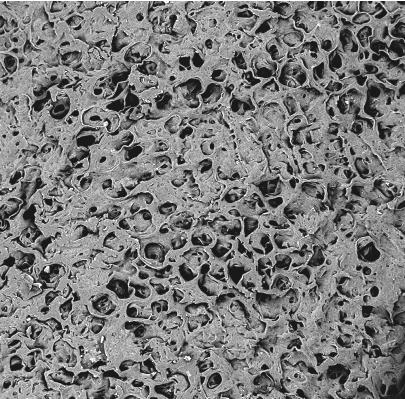

[0029] Dissolve 0.5g of sodium alginate in 10mL of pure water, and vacuum defoam for 6h. Take 1mL of sodium alginate solution and pour it into a flat-bottomed sample dish, and spread it flat with a thickness of 1mm. Then put the sample dish into a freezer and freeze it at -20°C for 5h. In addition, to prepare a thawing coagulant, mix 75g of absolute ethanol, 20g of anhydrous calcium chloride, 2g of glycerin, and 3g of water, and stir to dissolve at room temperature. Then, 3 mL of thawing coagulant was injected into the frozen sodium alginate solution, and it was thawed and cross-linked and solidified at -20°C for 8 hours. Afterwards, the porous alginate membrane is taken out, rinsed with pure water, and vacuum-dried at 50°C. The obtained porous alginate membrane has a thickness of about 1mm, is soft and porous. The pore structure characteristics of the porous alginate membrane obtained in this example are similar to those in Example 1 (see image 3 with Figure 4 ). The w...

Embodiment 3

[0031] Dissolve 0.7g of sodium alginate in 10mL of pure water, and vacuum defoam for 12h. Take 2mL of sodium alginate solution and pour it into a flat-bottomed sample dish, make it flow-cast flat, with a thickness of 2mm, and then put the sample dish into a freezer and freeze it at -80°C for 3h. In addition, to prepare a thawing coagulant, mix 85g of absolute ethanol, 10g of anhydrous calcium chloride, 2g of glycerin, and 3g of water, and stir to dissolve at room temperature. Then, 20 mL of thawing coagulant was injected into the frozen sodium alginate solution, and it was thawed and cross-linked and solidified at -80°C for 12 hours. Afterwards, the porous alginate membrane is taken out, rinsed with pure water, and vacuum-dried at 25°C. The obtained porous alginate membrane has a thickness of about 2mm, is soft and porous, has good liquid absorption and moisturizing effect, and can be used for wound dressings, hemostatic sponges or cell scaffolds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com