Silicon-based macroporous cation exchange resin and method for separating Po and preparing planar reference source

A cation exchange, silicon-based technology, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problems of unqualified equipment, incomplete separation, slow adsorption kinetics, etc., achieve efficient separation, improve efficiency, improve credibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

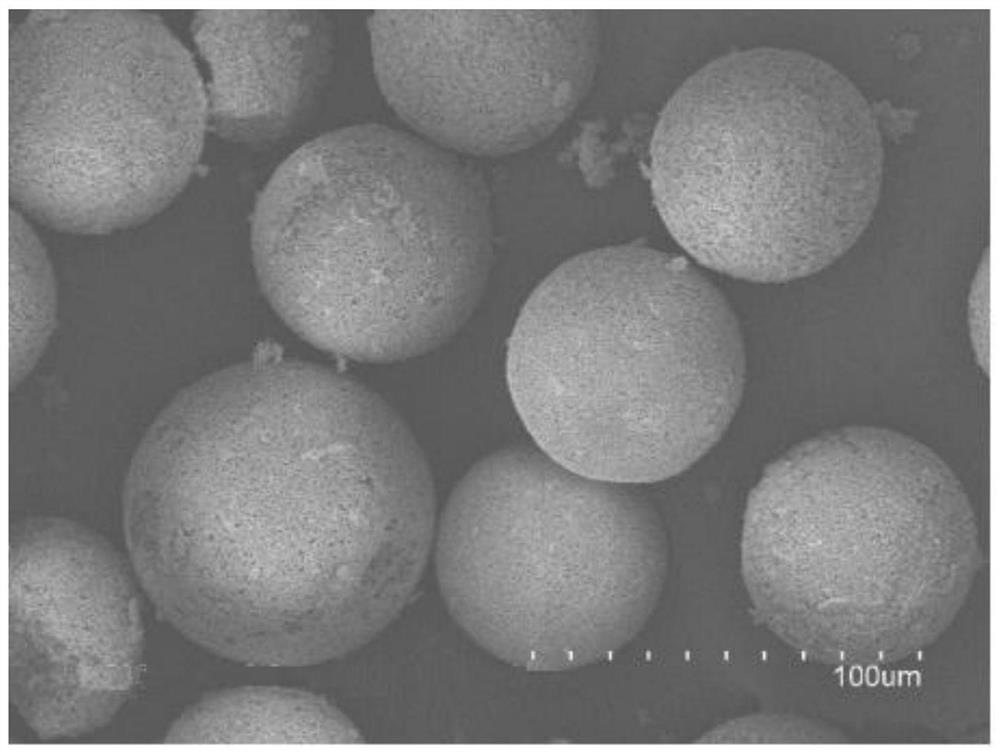

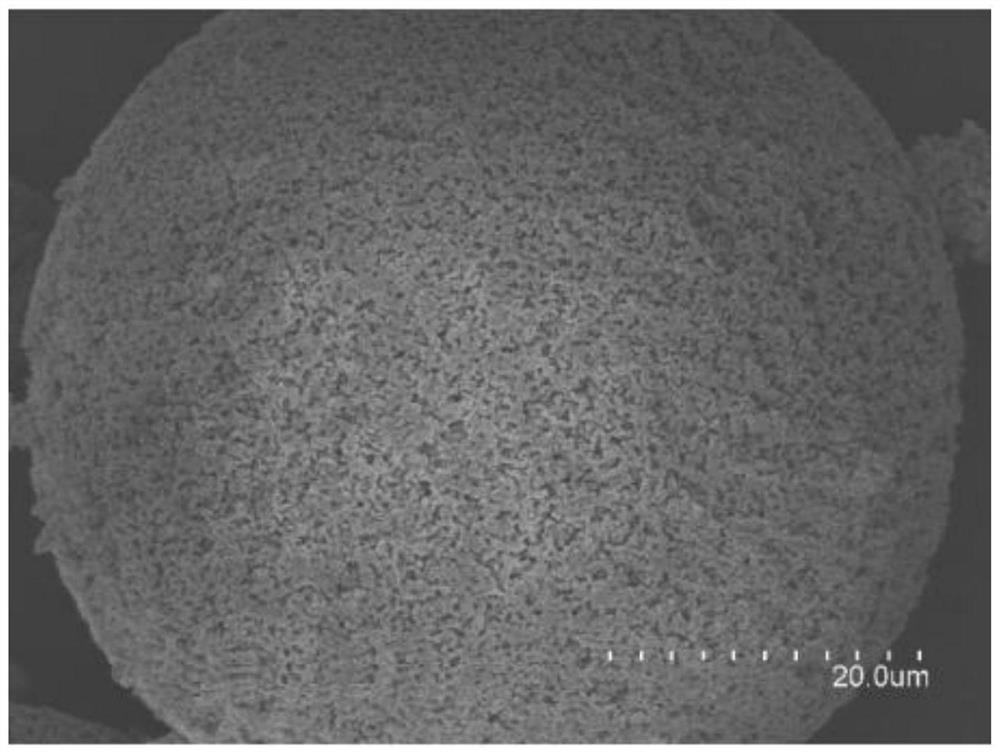

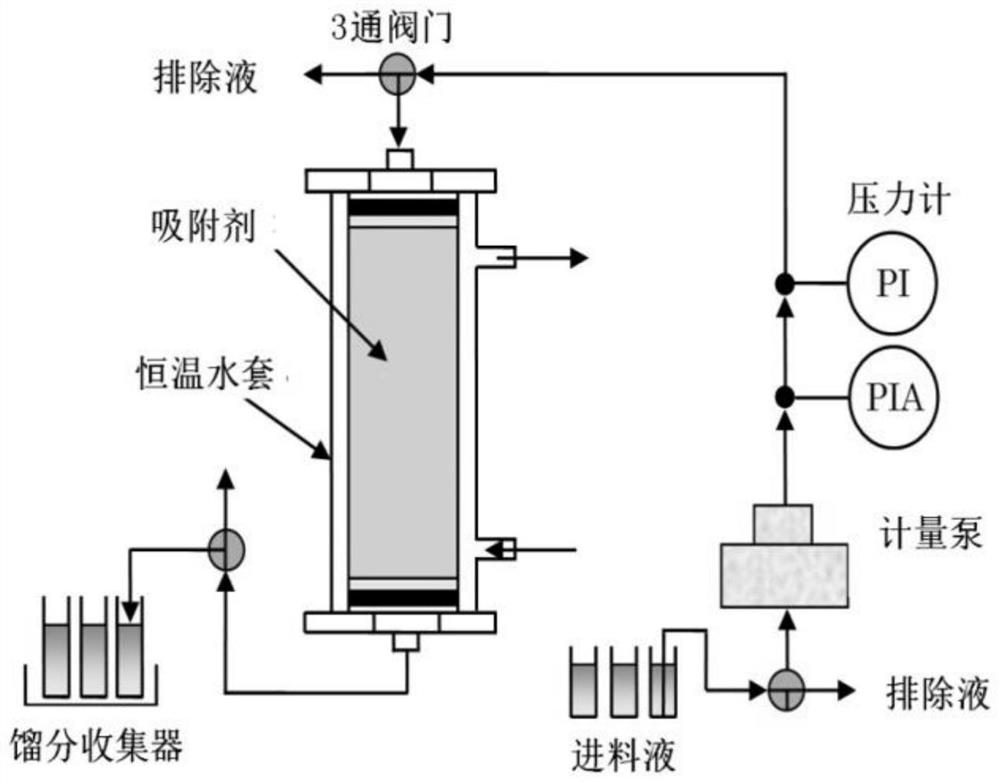

[0103] This embodiment provides a silicon-based macroporous cation-exchange resin and a solid-phase chromatography device; the silicon-based macroporous cation-exchange resin is prepared by the following preparation method:

[0104] (a) Mix 0.2 part of styrene, 0.1 part of divinylbenzene, 0.01 part of AIBN and 0.5 part of acetophenone to obtain a mixed oil phase, and set aside; place 1 part of macroporous silica particles in a rotating In the distillation bottle of the evaporator, add the above-mentioned mixed oil phase to make it fully mixed with the silica particles; heat the reaction system in a water bath, and gradually raise the temperature to 90°C for 10 hours at a constant temperature; Rinse with acetone, and repeatedly suction filter with acetone to prepare the silicon-based macroporous cation exchange resin;

[0105] (2) Transfer the silicon-based macroporous cation exchange resin into the distillation bottle of the rotary evaporator again, add 1 part of toluene, add ...

Embodiment 2

[0108] This embodiment provides a silicon-based macroporous cation-exchange resin and a solid-phase chromatographic device, and the silicon-based macroporous cation-exchange resin is prepared by the following preparation method:

[0109] (a) Mix 0.25 parts of styrene, 0.15 parts of divinylbenzene, 0.015 parts of V-40 and 0.8 parts of acetophenone to obtain a mixed oil phase for subsequent use; place 1 part of macroporous silica particles In the distillation bottle of the rotary evaporator, add the above-mentioned mixed oil phase to make it fully mixed with the silica particles; heat the reaction system in a water bath, and gradually raise the temperature to 80°C for 12 hours at a constant temperature; The product is washed with acetone, and is repeatedly suction-filtered with acetone to prepare the silicon-based macroporous cation exchange resin;

[0110] (2) Transfer the silicon-based macroporous cation exchange resin into the distillation bottle of the rotary evaporator agai...

Embodiment 3

[0113] This embodiment provides a silicon-based macroporous cation-exchange resin and a solid-phase chromatographic device, and the silicon-based macroporous cation-exchange resin is prepared by the following preparation method:

[0114] (a) Mix 0.3 part of styrene, 0.2 part of divinylbenzene, 0.02 part of AIBN and 1 part of tetrabutyl phthalate to obtain a mixed oil phase, set aside; place 1 part of macroporous silica particles In the distillation bottle of the rotary evaporator, add the above-mentioned mixed oil phase to make it fully mixed with the silica particles; heat the reaction system in a water bath, and gradually raise the temperature to 100°C for 9 hours at a constant temperature; The product is washed with acetone, and is repeatedly suction-filtered with acetone to prepare the silicon-based macroporous cation exchange resin;

[0115] (2) Transfer the silicon-based macroporous cation exchange resin into the distillation bottle of the rotary evaporator again, add 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com