Method for evaluating palatability of coated enrofloxacin by measuring encapsulation efficiency

A technology of encapsulation rate and palatability, which is applied in the field of medicine and chemical industry, can solve the problems affecting pig feed intake and achieve good reproducibility, maintain temperature and stirring speed, high stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

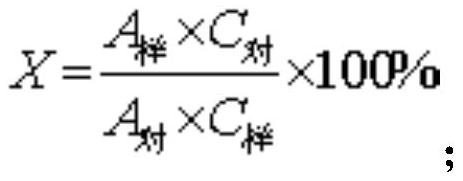

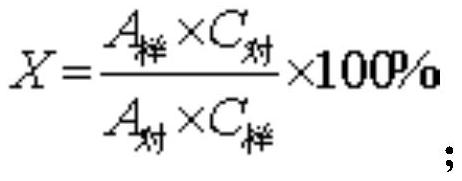

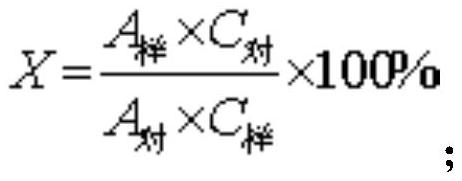

Image

Examples

Embodiment 1

[0024] Use reagents:

[0025] Acetonitrile;

[0026] 2. Triethylamine;

[0027] 3. Phosphoric acid;

[0028] 4. Purification water;

[0031] Pre-tuning reagent:

[0032] 1. Phosphate solution: Take 6.805 g of sodium phosphate and 0.88 g of sodium hydroxide, add water to 1000 mL, and adjust the pH to 6.86 with 2 mol / L of sodium hydroxide solution or dilute phosphoric acid solution.

[0033] 2. Mobile phase: The phosphoric acid solution of 0.025 mol / L was adjusted by triethylamine to a pH of 3.0, and then the acetonitrile and the phosphoric acid solution were mixed in volume ratio of 17:83.

[0034] Use the instrument:

[0035] 1. Generally used glassware commonly used in the laboratory;

[0036] 2. Dissolution meter;

[0037] 3. High performance liquid chromatography.

[0038] Experimental steps:

[0039] a) Preparation of sample solution:

[0040] A 500.0 ml of a phosphate solution was quantified and placed in a disso...

Embodiment 2

[0058] Add 1.016 g of the coated Ennovia (Xinchang and Baosheng Technology Co., Ltd.) and stirring. Others in the same embodiment.

[0059] The calculation results are shown in Table 2 below:

[0060]

[0061] Table 2 Embodiment of the encapsulation rate test results

Embodiment 3

[0063] Takenno Sand 0.5mg, 1.0 mg and 1.5 mg of 6 copies, and added to the dissolution cup, and the recovery measurement was carried out according to the establishment method, and the results were as follows:

[0064] Add amount Recovery rate(%) Variation coefficient (n = 6) 0.5mg 85.3、78.9、80.4、83.2、84.1、86.5 3.5% 1.0mg 88.7、89.9、91.3、86.2、87.9、92.1 2.5% 1.5mg 97.3、95.2、96.4、93.8、98.7、94.8 1.9%

[0065] Table 3 method of recovery rate test results

[0066] Referring to Table 3, the average recovery rate is between 78.9-98.7%, between 1.9-3.5%, indicating that this method has better recovery, stability and repetition, fully meet the packaged Enno Sand Daily inspection requirements for star package levels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com