Method for testing hygroscopicity of 3,4-dinitropyrazole

A technology of dinitropyrazole and testing methods, which is applied in chemical method analysis, measuring devices, and the use of substance absorption and weighing, etc., can solve problems such as restricting applications, and achieve the effects of simple operation, accurate data, and avoiding weighing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of test method of 3,4-dinitropyrazole hygroscopicity, comprises the following steps:

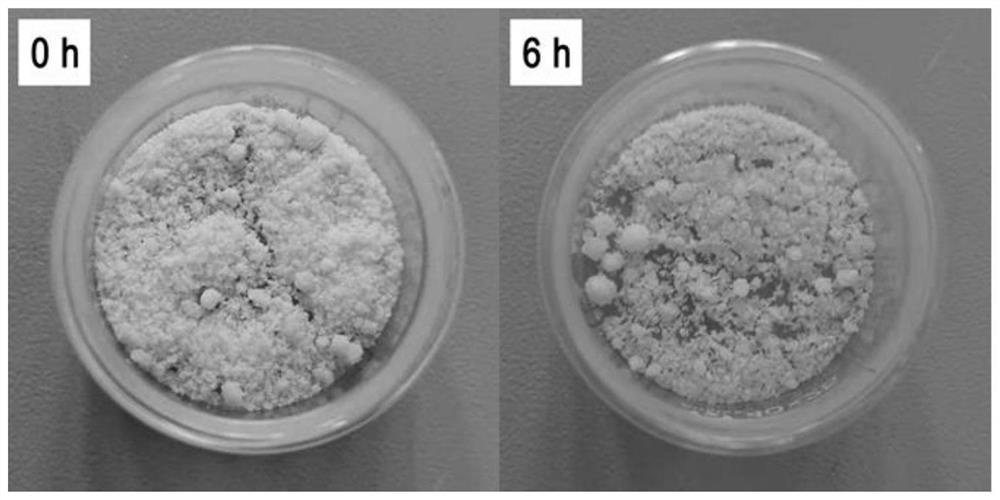

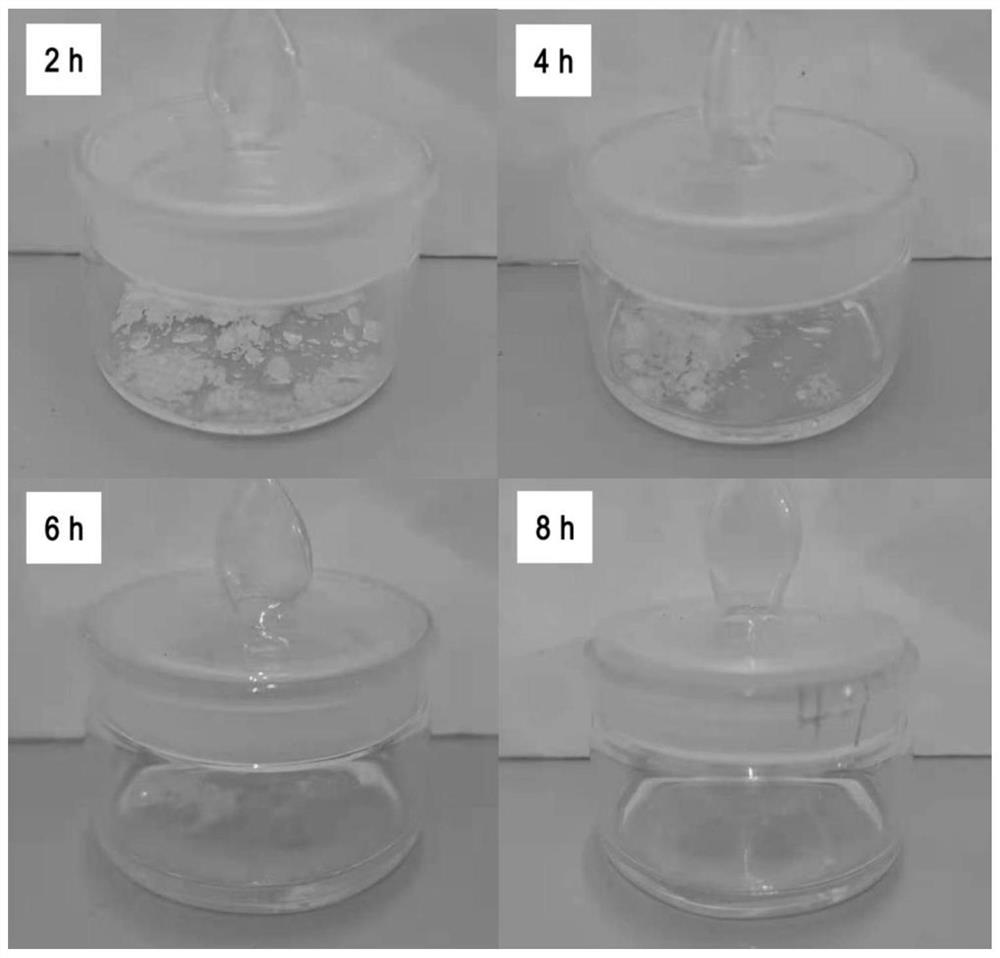

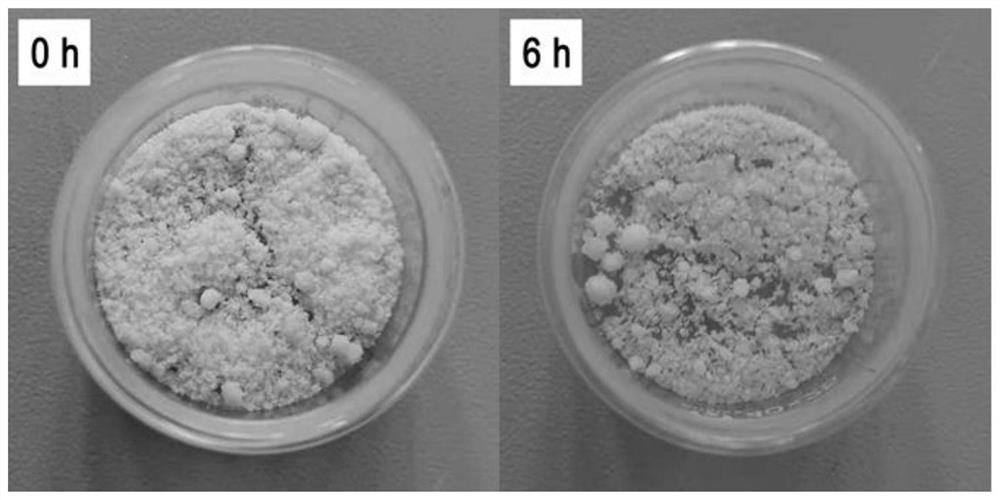

[0023] (1) DNP solid samples obtained by N-nitration, thermal rearrangement, and C-nitration at room temperature were dried in a vacuum oven at 55°C and a vacuum of 0.1MPa for 3 hours to constant weight, and about 1g of the sample was passed through Karl Fischer moisture titrator titration determined water content at 0.018%;

[0024] (2) Divide the sample into several groups of samples, each group weighs 1.0000±0.0005g of the sample, puts it in a weighing box of known weight that has been washed and dried in advance, and records the total mass of each portion; put the weighing box Take off the lid and put it in a constant temperature and humidity box, set a fixed temperature and relative humidity for moisture absorption for a specified time, seal the lid and put it in a desiccator to cool down to room temperature as a whole, weigh and calculate the moisture absorption rate.

...

Embodiment 2

[0028] A kind of test method of 3,4-dinitropyrazole hygroscopicity, comprises the following steps:

[0029] (1) DNP solid samples obtained by N-nitration, thermal rearrangement, and C-nitration at room temperature were dried in a vacuum oven at 50°C and a vacuum of 0.08MPa for 2h to constant weight, and about 1g of the sample was passed through Karl The moisture content was determined to be 0.02% by Fischer moisture titrator titration;

[0030] (2) Weigh a sample of 1.0000±0.0005g, place it in a weighing box of known weight that has been washed and dried in advance, and record the total mass; then remove the cover of the weighing box and put it in a constant temperature and humidity box , set the temperature at 30°C, the relative humidity at 50%, and the moisture absorption time at 24 hours, and calculate the moisture absorption rate of the sample to be 1.0%.

Embodiment 3

[0032] A kind of test method of 3,4-dinitropyrazole hygroscopicity, comprises the following steps:

[0033] (1) DNP solid samples obtained through N-nitration, thermal rearrangement, and C-nitration at room temperature were dried in a vacuum oven at 53°C and a vacuum of 0.09MPa for 2.5h to constant weight, and about 1g of the sample was collected by Karl Fischer moisture titrator titration determines the water content at 0.015%;

[0034] (2) Weigh a sample of 1.0000±0.0005g, place it in a weighing box of known weight that has been washed and dried in advance, and record the total mass; then remove the cover of the weighing box and put it in a constant temperature and humidity box , set the temperature at 40°C, the relative humidity at 75%, and the moisture absorption time at 48 hours, and calculate the moisture absorption rate of the sample to be 3.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com