Supersonic air injection device

A supersonic, air technology, used in jet pumps, machines/engines, non-displacement pumps, etc., can solve problems such as affecting airflow mixing, airflow disturbance, and airflow that cannot be mixed well, to reduce the degree of mutual attraction, Improves mixing uniformity and reduces airflow disturbance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

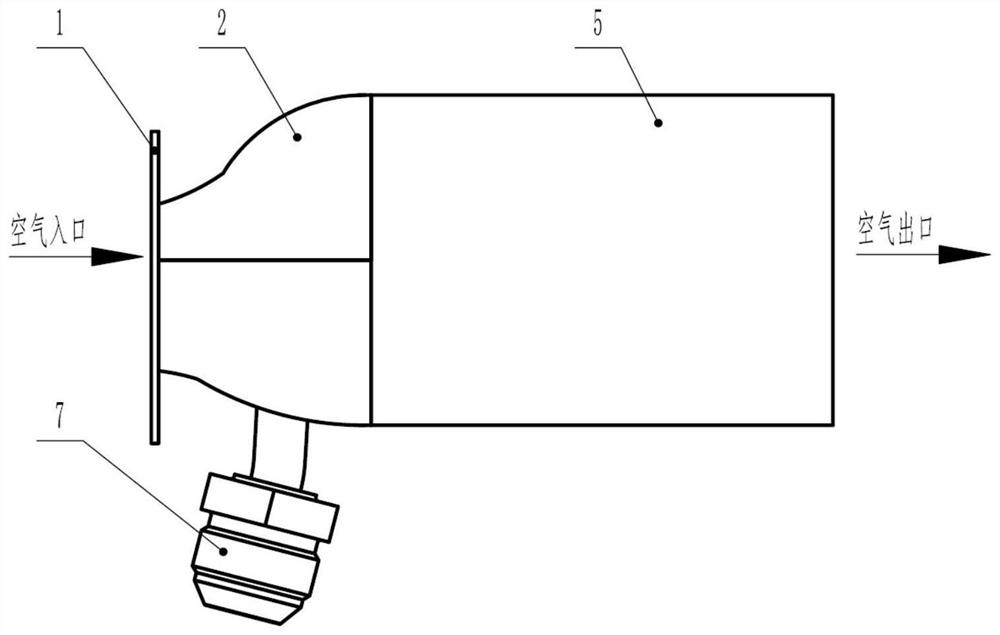

[0041] Such as Figure 1 to Figure 9 As shown, in this embodiment, the supersonic air injection device includes a mounting plate 1 , an air passage transition section 2 , an injection pipe 3 , a nozzle pipe 4 , a secondary cooling air passage 5 , a support plate 6 and an inlet nozzle 7 . All components of the ejection device are connected together by welding; image 3 , Figure 4 , Figure 7 The shown mounting plate 1, air duct tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com