Roller grinding fluid and preparation method thereof

A technology of grinding fluid and roll, which is applied in the field of roll grinding fluid and its preparation, can solve the problems of poor lubricating performance and poor wettability, and achieve the effects of excellent lubricating effect, high lubricating performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

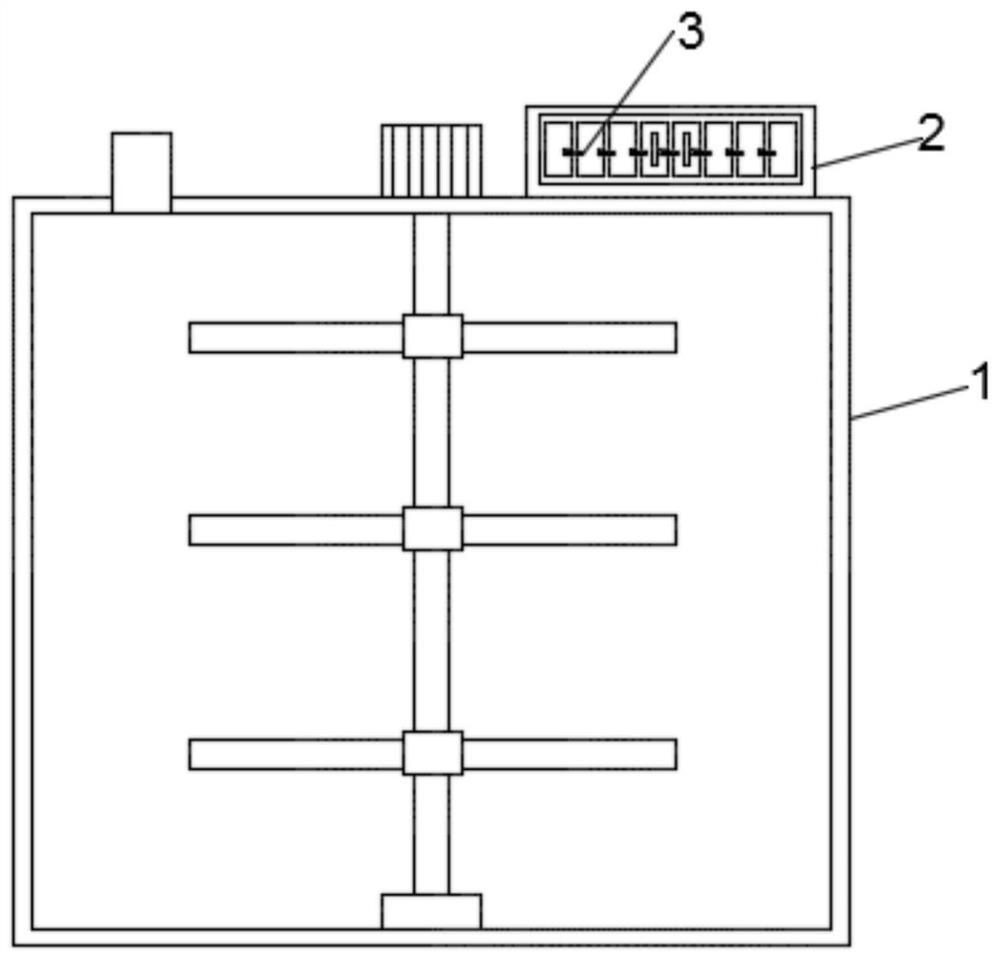

[0020] Add 65% of demineralized water into the reaction kettle 1 through the water inlet pipe on the reaction kettle 1 and start stirring, pull out one feeding box 202 in the feeding assembly 2, drive other feeding boxes 202 to move out, and add to the multiple feeding boxes 202 respectively Ricinoleic acid soap 20%, Polyethylene Glycol 6%, antirust agent 5%, cosolvent 2% and defoamer 2%, push back feeding box 202 after feeding finishes, open and be positioned at charging box 202 on the bottom wall Control the valve, the raw materials enter the reactor 1, and continue to stir, and continue to stir for 20 minutes after feeding.

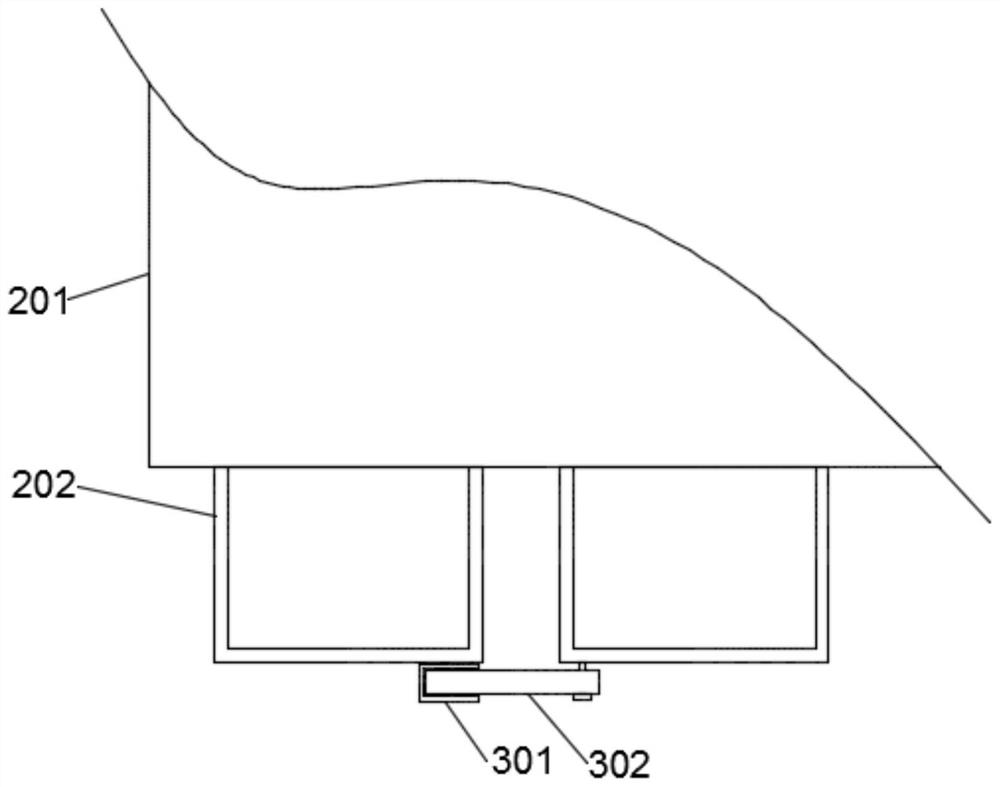

[0021] Wherein, a kind of preparation device of roll grinding liquid comprises reactor 1, and the top wall of reactor 1 is provided with feeding assembly 2, and feeding assembly 2 can add multiple raw materials to reactor 1 at the same time, and feeding assembly 2 includes outer frame 201, the inside of the outer frame 201 is provided with a plurality ...

Embodiment 2

[0024] Add 59% of demineralized water into the reaction kettle 1 through the water inlet pipe on the reaction kettle 1 and start stirring, pull out one feeding box 202 in the feeding assembly 2, drive other feeding boxes 202 to move out, and add to the multiple feeding boxes 202 respectively Ricinoleic acid soap 22%, macrogol 7%, antirust agent 6%, cosolvent 3% and defoamer 3%, push back charging box 202 after feeding finishes, open and be positioned at charging box 202 on the bottom wall Control the valve, the raw materials enter the reactor 1, and continue to stir, and continue to stir for 30 minutes after feeding.

[0025] Wherein, a kind of preparation device of roll grinding liquid comprises reactor 1, and the top wall of reactor 1 is provided with feeding assembly 2, and feeding assembly 2 can add multiple raw materials to reactor 1 at the same time, and feeding assembly 2 includes outer frame 201, the inside of the outer frame 201 is provided with a plurality of feeding...

Embodiment 3

[0028] Add 54% of demineralized water into the reactor 1 through the water inlet pipe on the reactor 1 and start stirring, pull out one feeding box 202 in the feeding assembly 2, drive the other feeding boxes 202 to move out, and add to the multiple feeding boxes 202 respectively Ricinoleic acid soap 23%, Polyethylene Glycol 8%, antirust agent 7%, cosolvent 4% and defoamer 4%, push back charging box 202 after feeding finishes, open and be positioned at charging box 202 on the bottom wall Control the valve, the raw materials enter the reactor 1, and continue to stir, and continue to stir for 20 minutes after feeding.

[0029] Wherein, a kind of preparation device of roll grinding liquid comprises reactor 1, and the top wall of reactor 1 is provided with feeding assembly 2, and feeding assembly 2 can add multiple raw materials to reactor 1 at the same time, and feeding assembly 2 includes outer frame 201, the inside of the outer frame 201 is provided with a plurality of feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com