A kind of carbon black dispersion and its preparation method and application

A dispersion and carbon black technology, applied in the direction of single-component polyester rayon, dyed low-molecular organic compound treatment, fibrous filler, etc. Problems such as poor spinnability of ester, agglomeration of carbon black particles, etc., to achieve good spinnability, improved stability, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

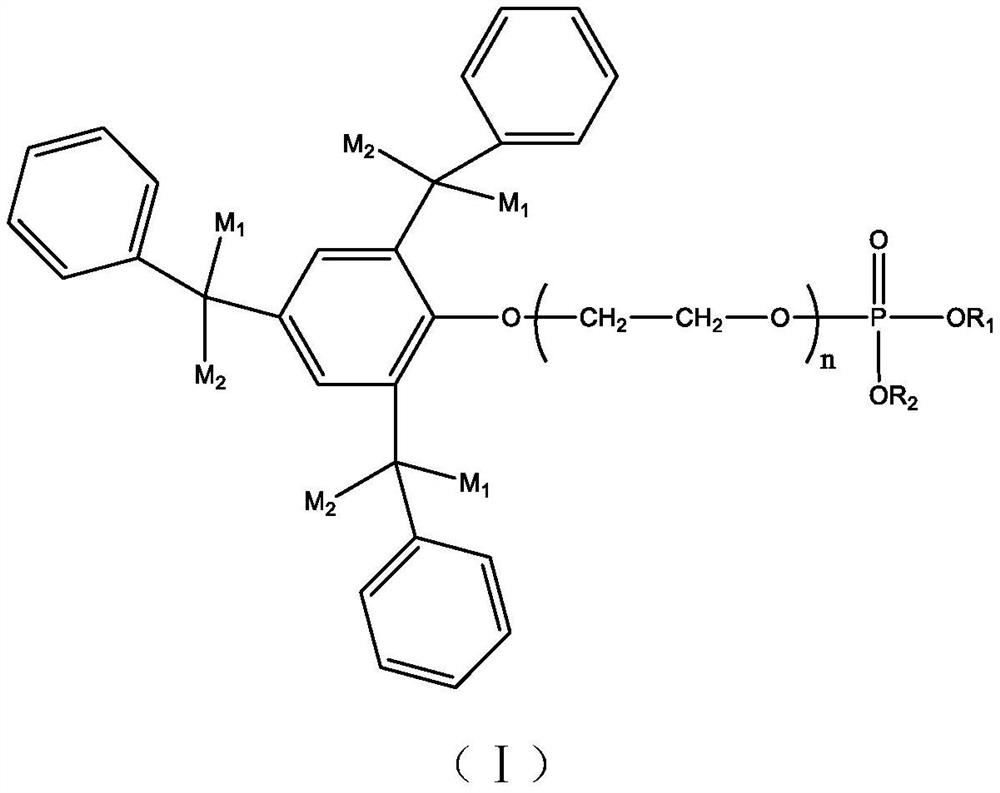

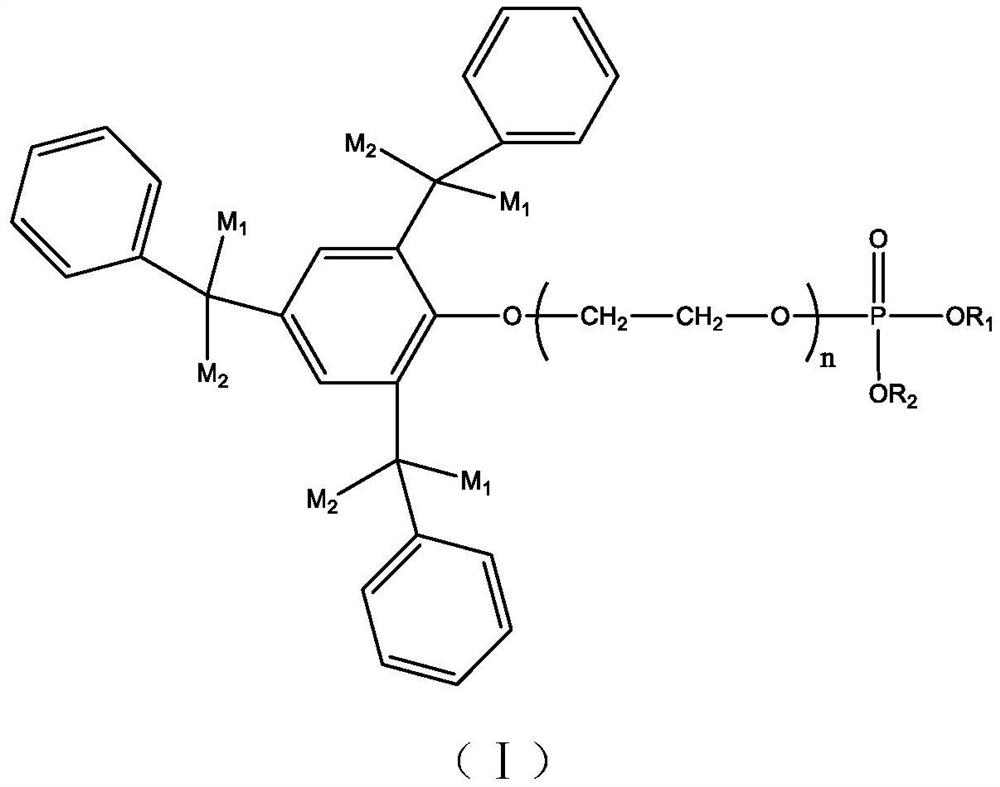

Method used

Image

Examples

Embodiment 1

[0038] Add carbon black with hydroxyl groups on the surface and p-hydroxybenzoic acid at a mass ratio of 1:0.05, add N,N-dimethylformamide accounting for 15% of the mass of carbon black with hydroxyl groups on the surface, and knead with a kneader after uniform dispersion 45min, obtain modified carbon black;

[0039] Disperse 3 parts of surfactant A by mass and 3 parts of surfactant B1 by mass into 74 parts of ethylene glycol by mass, add 20 parts by mass of modified carbon black, mix well, and use hydrogen Sodium oxide was used to adjust the pH value to 8.0, and the carbon black dispersion was obtained through dispersion, grinding, filtration and defoaming.

Embodiment 2

[0041] Add carbon black with hydroxyl groups on the surface and m-hydroxybenzoic acid at a mass ratio of 1:0.06, add N,N-dimethylformamide accounting for 10% of the mass of carbon black with hydroxyl groups on the surface, and knead with a kneader after uniform dispersion 30min, obtain modified carbon black;

[0042] Disperse 2 parts of surfactant A by mass and 5 parts of surfactant B2 by mass into 63 parts of ethylene glycol, add 30 parts by mass of modified carbon black, mix well, and use hydrogen Potassium oxide is used to adjust the pH value to 7.0, and the carbon black dispersion is obtained through dispersion, grinding, filtration and defoaming.

Embodiment 3

[0044] Add carbon black with hydroxyl groups on the surface and 3,5-dihydroxybenzoic acid with a mass ratio of 1:0.07, add N,N-dimethylformamide accounting for 16% of the carbon black with hydroxyl groups on the surface, and disperse evenly. Knead with a kneader for 40 minutes to obtain modified carbon black.

[0045] The quality is 5 parts of surfactant A, the quality is 4 parts of surfactant B3, dispersed in the quality is 51 parts of ethylene glycol, the addition of quality is 40 parts of modified carbon black, the quality is 0.01 part of 1 , 2-benzisothiazolin-3-one, after fully mixing, adjust the pH value to 9.0 with potassium hydroxide, and obtain a carbon black dispersion through dispersion, grinding, filtration, and defoaming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com