Hand lay-up epoxy resin composite material for wind power blade

A technology of epoxy resin and wind turbine blades, which is applied in the field of advanced composite materials, can solve problems such as temperature changes, hand lay-up anti-sagging and fiber wettability, curing speed and production efficiency, and temperature changes can not be taken into account at the same time, to achieve improvement Good heat resistance, wettability improvement, crosslink density, and anti-sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

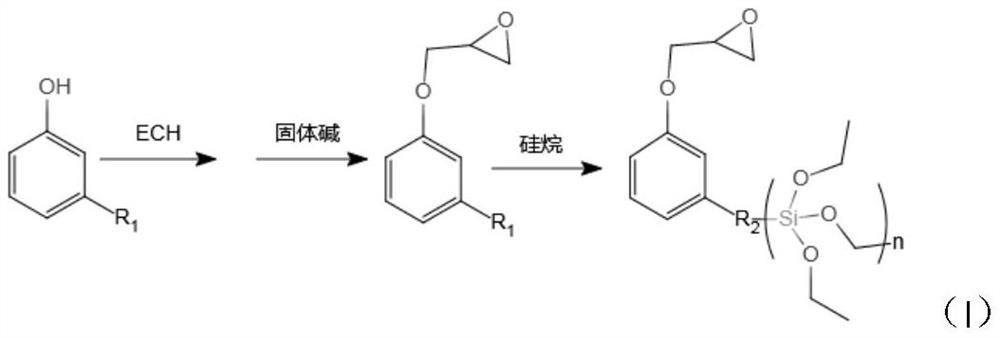

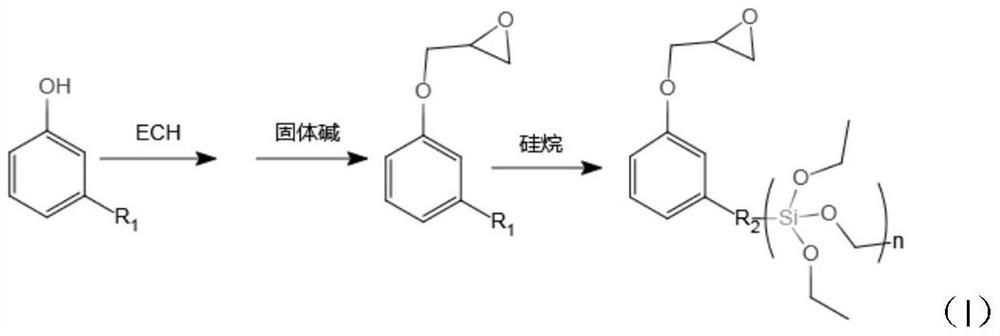

[0036] This preparation example adopts the following method to prepare silanized cardanol modified epoxy resin I, comprising the following steps:

[0037](1) Take cardanol and epichlorohydrin according to the weight ratio of 1:5, add quaternary ammonium salt catalyst benzyltriethylammonium chloride, the consumption is 1% of the quality of cardanol, feed dry nitrogen, and heat up to 110 ℃ for 5 hours; after the reaction, lower the temperature to 60 ℃, add solid alkali sodium hydroxide in batches, the amount is 0.4 times the mass of cardanol, and continue the reaction for 3 hours. , remove excess epichlorohydrin, obtain cardanol glycidyl ether;

[0038] (2) Take by weighing the cardanol glycidyl ether and triethoxysilane prepared in step (1) according to the ratio of 1:0.9 by weight, after mixing evenly, add 1.5 times the xylene of the cardanol glycidyl ether quality, And Castel catalyst, the dosage is 0.008% of the mass of cardanol glycidyl ether, heated up to 120°C for 4 hour...

preparation example 2

[0043] This preparation example adopts the following method to prepare silanized cardanol modified epoxy resin II, comprising the following steps:

[0044] (1) Weigh cardanol and epichlorohydrin according to the weight ratio of 1:3, add quaternary ammonium salt catalyst tetrabutylammonium bromide, the dosage is 0.7% of the mass of cardanol, feed dry nitrogen, and heat up to 120°C for reaction 3h; after the reaction, lower the temperature to 65°C, add solid alkali potassium hydroxide in batches, the dosage is 0.5 times the mass of cardanol, and continue the reaction for 4h. Excessive epichlorohydrin, obtains cardanol glycidyl ether;

[0045] (2) Take the cardanol glycidyl ether and triethoxysilane prepared by step (1) according to the ratio of 1:1.1 by weight, after mixing evenly, add 1.5 times the xylene of the cardanol glycidyl ether quality, As well as Castel catalyst, the dosage is 0.006% of the mass of cardanol glycidyl ether, and the temperature is raised to 110°C for 6 ...

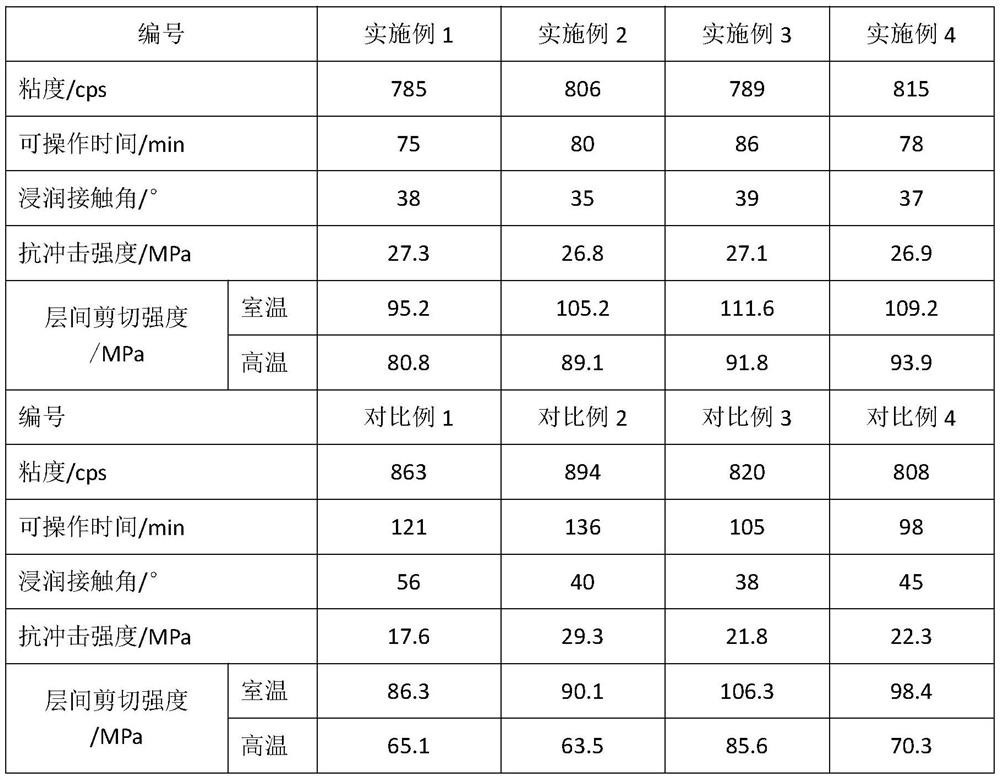

Embodiment 1

[0047] A kind of hand lay-up epoxy resin composite material for wind power blades, comprising A component and B component, the weight ratio of said A component and B component is 100:20;

[0048] The A component includes the following raw materials by weight: 100 parts of bisphenol A type epoxy resin, 30 parts of silanized cardanol modified epoxy resin I, 8 parts of bisphenolic acid epoxy resin, 25 parts of reactive diluent, 2 parts of silane coupling agent, 1 part of anti-sag additive, 3 parts of filler; 40 parts of solvent;

[0049] The B component includes the following raw materials in parts by weight: 30 parts of curing agent, 5 parts of curing accelerator, 5 parts of vinyl ether compound, 1 part of defoamer, and 5 parts of solvent.

[0050] Described bisphenol A type epoxy resin has the epoxy equivalent of 320g / eq, and viscosity is 6500cps; Described bisphenol acid epoxy resin has the structure of formula (II): And an epoxy equivalent of 220g / eq.

[0051] The reactive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com