Zinc-doped indium oxide powder, sputtering target material and preparation method thereof

A technology of sputtering target material and indium oxide, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of powder agglomeration and poor dispersion, and achieve stable reaction system, The effect of high density and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing zinc-doped indium oxide powder, comprising the following steps:

[0024] 1) After mixing the indium salt, the zinc salt, the precipitating agent and water, perform a hydrothermal reaction to obtain a precursor mixed solution; the temperature of the hydrothermal reaction is 150-250° C., and the time is 5-20 hours;

[0025] 2) Washing, drying and calcining the precursor mixed liquid in the step 1) sequentially to obtain zinc-doped indium oxide powder; the calcining temperature is 400-800°C.

[0026] In the invention, after mixing indium salt, zinc salt, precipitating agent and water, hydrothermal reaction is carried out to obtain precursor mixed solution.

[0027] In the present invention, the indium salt is preferably at least one of indium nitrate, indium sulfate and indium chloride, more preferably indium nitrate. The indium salt in the present invention is preferably mixed in the form of an indium salt solution, and the c...

Embodiment 1

[0048] The preparation method of indium nitrate solution:

[0049] The nitric acid solution is reacted with metal indium to prepare an indium nitrate solution; the concentration of indium nitrate in the reaction solution is calculated according to the mass loss before and after the reaction of indium ingots; deionized water is added to the reaction solution so that the concentration of indium nitrate is 1.5mol / L, Indium nitrate solution was obtained.

[0050] Preparation method of zinc-doped indium oxide powder

[0051] 1) 359g ZnSO 4 ·7H 2 Mix O solid with 833 mL of the above indium nitrate solution (In / Zn=1:1), add deionized water until the total volume of the solution is 2500 mL, stir at room temperature to completely dissolve the solid to obtain a mixed solution, in which the content of indium atoms is 1.25 mol ;

[0052] 2) Slowly add 25% ammonia water to the mixed solution until the pH value of the solution is 7, transfer to a hydrothermal reactor and react at 180°C ...

Embodiment 2

[0059] The preparation method of indium nitrate solution: identical with embodiment 1.

[0060] The preparation method of zinc-doped indium oxide powder: in step 2), slowly add 25% ammonia water to the mixed solution until the pH value of the solution is 5, and the other steps are exactly the same as in Example 1.

[0061] The preparation method of the sputtering target: the zinc-doped indium oxide powder obtained in this example is used as the raw material, and the rest is exactly the same as that of Example 1.

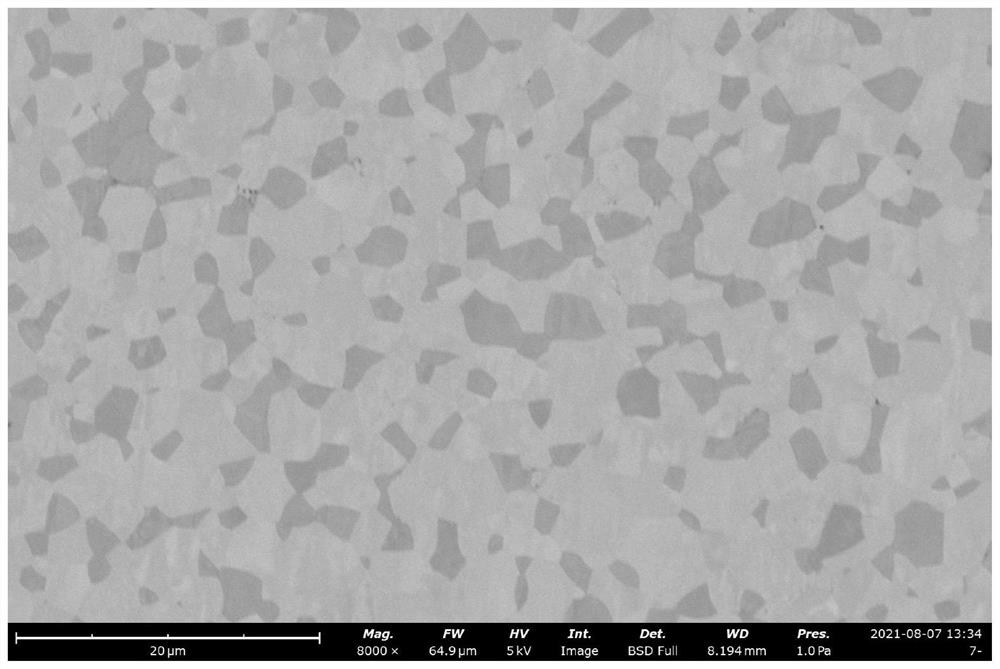

[0062] The IZO sputtering target can achieve densification, and the main phase is Zn atoms doped to In 2 o 3 phase, the rectangular secondary phase is Zn 3 In 2 o 6 , the relative density is 99.2%, and the average grain size is 8μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com