Heat shrink film of reclaimed material and preparation method of heat shrink film

A heat-shrinkable film and recycled material technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of uneven film thickness, uneven shrinkage, uneven color, etc., and achieve good thickness The effects of uniformity, wide range of shrinkage, and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

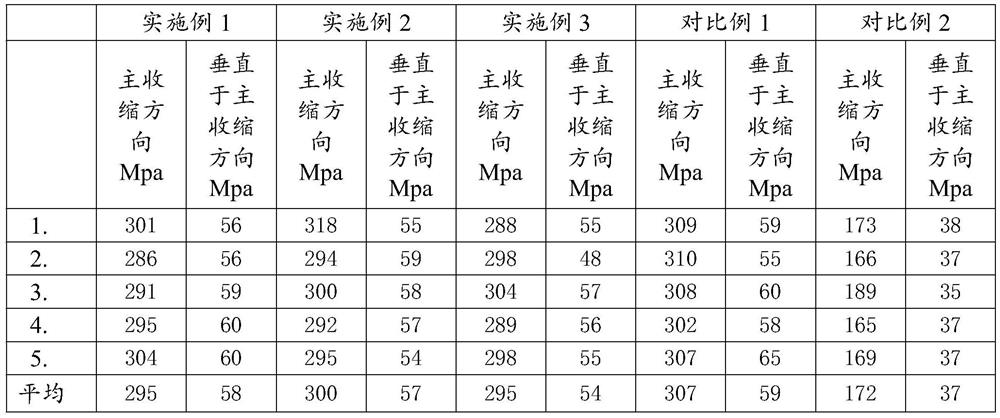

Embodiment 1

[0043] A heat-shrinkable film of regenerated materials, containing 25% by mass fraction of recycled polyester raw materials and 75% by mass fraction of virgin polyester raw materials, wherein the regenerated polyester raw materials are modified by copolymerization of isophthalic acid A copolyester material of polyethylene terephthalate, wherein the isophthalic acid component accounts for 2.5mol% of the total diacid component of the recycled polyester raw material; the raw polyester raw material is copolymerized modified polyethylene terephthalate A copolyester material of ethylene glycol diformate, wherein the dibasic acid in the modified component accounts for 20mol% of the total diacid component of the raw polyester raw material, and the dibasic alcohol in the modified component accounts for 20mol% of the raw polyester 27 mol% of the total diol content of the raw material.

[0044] The modified components of virgin polyester raw materials are diethylene glycol and neopentyl ...

Embodiment 2

[0058] A heat-shrinkable film of recycled materials, containing 45% by mass fraction of recycled polyester raw materials and 55% by mass fraction of virgin polyester raw materials, wherein the recycled polyester raw materials are modified by copolymerization of isophthalic acid A copolyester material of polyethylene terephthalate, wherein the isophthalic acid component accounts for 0.8mol% of the total diacid component of the recycled polyester raw material; the raw polyester raw material is copolymerized modified polyethylene terephthalate A copolyester material of ethylene glycol diformate, wherein the dibasic acid in the modified component accounts for 20mol% of the total diacid component of the raw polyester raw material, and the dibasic alcohol in the modified component accounts for 20mol% of the raw polyester 27 mol% of the total diol content of the raw material.

[0059] The modified components of virgin polyester raw materials are isophthalic acid, diethylene glycol an...

Embodiment 3

[0065] A heat-shrinkable film of regenerated materials, containing 60% by mass fraction of regenerated polyester raw materials and 40% by mass fraction of virgin polyester raw materials, wherein the regenerated polyester raw materials are modified by copolymerization of isophthalic acid A copolyester material of polyethylene terephthalate, wherein the isophthalic acid component accounts for 0.8mol% of the total diacid component of the recycled polyester raw material; the raw polyester raw material is copolymerized modified polyethylene terephthalate A copolyester material of ethylene glycol diformate, wherein the modified component includes one or more of dibasic acid or dibasic alcohol, and the dibasic acid in the modified component accounts for the total of the raw polyester raw material 20mol% of the diacid component, and the dihydric alcohol in the modified component accounts for 27mol% of the total diol component of the virgin polyester raw material.

[0066] The modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com