Deep washing and renovating device and washing and renovating method for glass surface of photovoltaic module

A technology for refurbishing devices and photovoltaic modules, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve problems such as limited effects, affecting power generation efficiency, and difficult cleaning, and achieve optimal power generation efficiency of components , significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

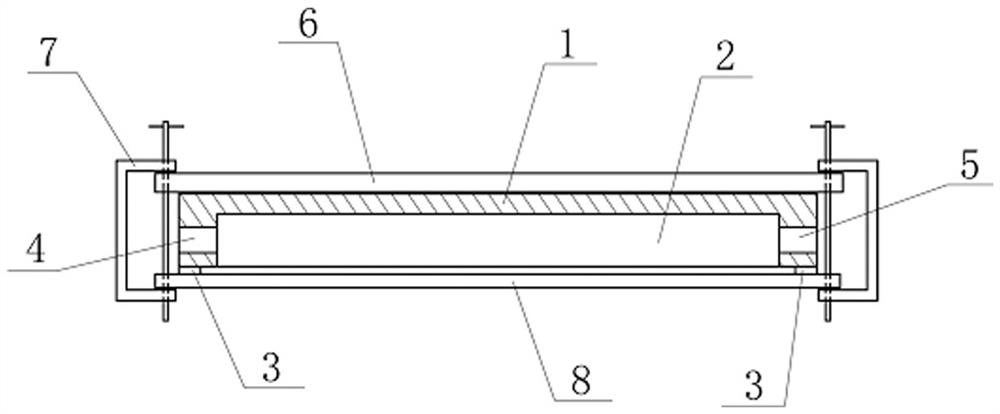

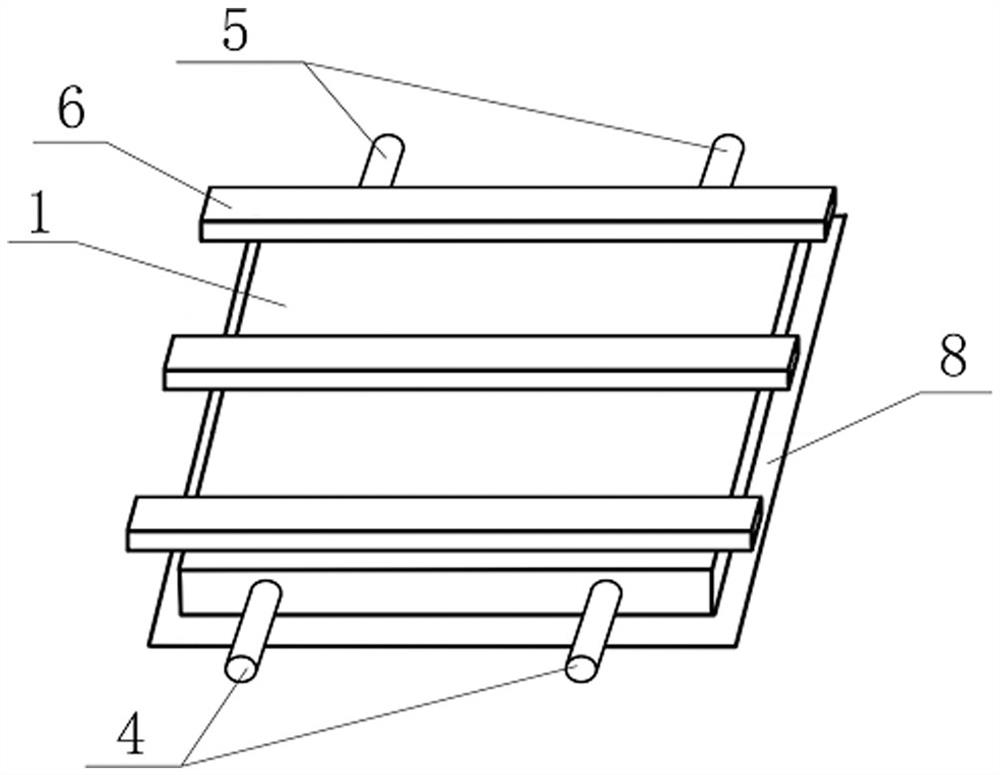

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , figure 2 and image 3 As shown, a device for deep cleaning and refurbishment of the glass surface of a photovoltaic module includes a cover body 1, a groove-type cleaning liquid cavity 2 is provided on the inside of the cover body 1, and a sealing tape 3 is provided around the cleaning liquid cavity 2, so that The cover body 1 is provided with a liquid inlet 4 and a liquid outlet 5 , and the cover body 1 is provided with a pressure fastener 6 .

[0030] Further, the sealing tape 3 is made of silica gel, NBR NBR, EPDM EPDM, VITDN fluororubber, PTFE polytetrafluoroethylene (also known as Teflon), PCTFE polychlorotrifluoroethylene, PEEK polyether Ether ketone or PI polyimide and other materials.

[0031] Further, the liquid inlet 4 and the liquid outlet 5 are arranged on the side of the cover body 1 , that is, the side wall of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com