Supported desulfurizer and preparation method and application thereof

A desulfurizer and supported technology, applied in the field of supported desulfurizer and its preparation, can solve the problems of waste of coal and wood, high price and unsuitable for large-scale production applications, etc. Beneficial for large-scale production applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

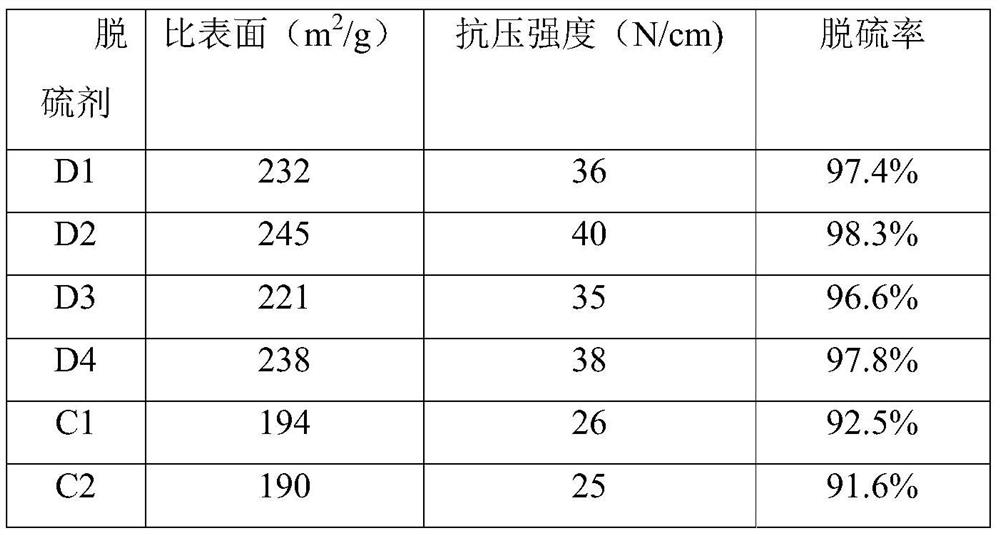

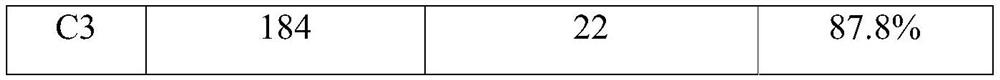

Examples

Embodiment 1

[0031] A preparation method of loaded desulfurizer, comprising the following steps:

[0032] 1) After washing, screening and drying furfural slag, put it into a carbonization furnace, carbonize at 350°C for 45 minutes, and cool to room temperature to obtain furfural slag carbonization material;

[0033] 2) Metal compound (ZnAc 2 , Fe(NO 3 ) 3 ), compound surfactant (nonionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate, anionic surfactant is sodium dodecylbenzenesulfonate, and fatty alcohol polyoxyethylene ether sodium sulfate and dodecane The mass ratio of sodium phenylsulfonate is 1:1), pore enhancer starch and strength enhancer SiO 2 Dissolve in the solvent methanol, and mix thoroughly to obtain the impregnating solution;

[0034] Among them, the molar ratio of metal compound, compound surfactant, porogen and strength enhancer is 4:1:0.1:0.2;

[0035] 3) Immersing the furfural slag carbonized material in the impregnation solution for 30 minutes, fil...

Embodiment 2

[0038] A preparation method of loaded desulfurizer, comprising the following steps:

[0039] 1) After washing, screening and drying the furfural slag, put it into a carbonization furnace, carbonize at 450°C for 30 minutes, and cool to room temperature to obtain a furfural slag carbonization material;

[0040] 2) Metal compound (ZnAc 2 , Fe(NO 3 ) 3 , Mg(NO 3 ) 2 ), compound surfactant (nonionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate, anionic surfactant is sodium lauryl sulfate, and fatty alcohol polyoxyethylene ether sodium sulfate and lauryl sulfate The mass ratio of sodium is 2:1), pore enhancer carboxymethyl cellulose and strength enhancer SiO 2 Dissolve in the solvent dimethyl sulfoxide, and mix thoroughly to obtain an impregnating solution;

[0041] Among them, the molar ratio of metal compound, compound surfactant, porogen and strength enhancer is 5:2:0.2:0.3;

[0042] 3) Immersing the furfural slag carbonized material in the impregnation...

Embodiment 3

[0045] A preparation method of loaded desulfurizer, comprising the following steps:

[0046] 1) After washing, screening and drying the furfural slag, put it into a carbonization furnace, carbonize at 450°C for 30 minutes, and cool to room temperature to obtain a furfural slag carbonization material;

[0047] 2) Metal compound (Cu(NO 3 ) 2 , AlCl 3 ), compound surfactant (nonionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate, anionic surfactant is sodium lauryl sulfate, and fatty alcohol polyoxyethylene ether sodium sulfate and lauryl sulfate The mass ratio of sodium is 2:1), pore enhancer carboxymethyl cellulose and strength enhancer SiO 2 Dissolve in the solvent ethanol and mix thoroughly to obtain the impregnating solution;

[0048] Among them, the molar ratio of metal compound, compound surfactant, porogen and strength enhancer is 4:1:0.1:0.2;

[0049] 3) Immersing the furfural slag carbonized material in the impregnation solution for 40 minutes, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com