Catalyst for synthesis of hydrogen peroxide and recovery, and method of preparing same

A production method and technology for hydrogen peroxide, which are applied in the directions of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of hydrogen peroxide production and regeneration efficiency decline, etc. , to achieve the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

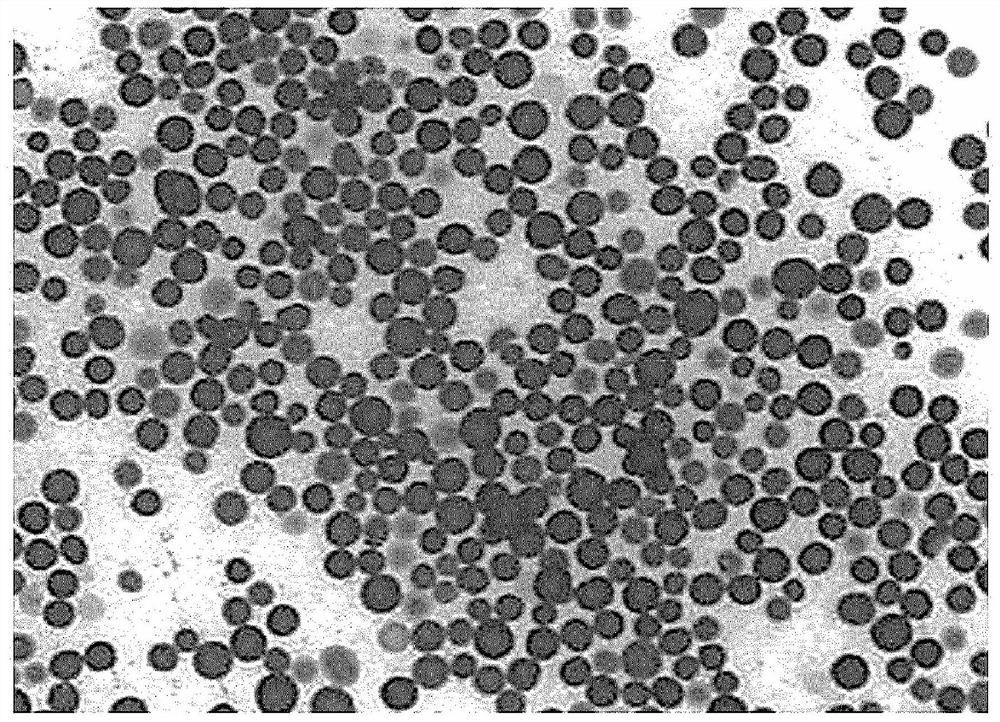

Image

Examples

Embodiment 1

[0026] As the carrier used in Example 1, γ-alumina was used, and boehmite (manufacturer: BASF, Germany, specific surface area: 250m 2 / g, pore volume: 0.55cm 3 / g, average pore size: 8.6nm) and used after firing. The alumina after firing is γ phase, and its specific surface area is 180m 2 / g.

[0027] Magnesium nitrate (Mg(NO 3 ) 2 .6H 2 O), as the precursor of cerium, cerium nitrate (Ce(NO 3 ) 3 .6H 2 O), while tetrachloropalladate (H 2 PdCl 4 ).

[0028] First, 5.0% of magnesium nitrate and 0.5% of cerium nitrate are mixed into the deionized water.

[0029] The manufactured magnesium-cerium composite solution was impregnated into the carrier by the incipient wetness method. The magnesium-cerium-loaded composition was subjected to a heat treatment process at 550° C. for 2 hours in an air environment, thereby fixing the metal.

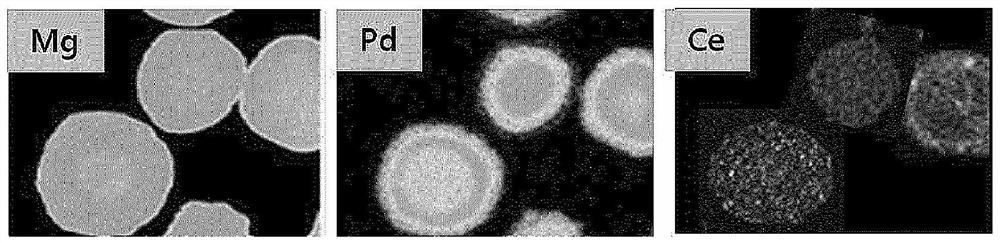

[0030] Next, add 100 g of magnesium-cerium-loaded alumina compositions to 200 ml of water, then add a palladium precursor equivalent to 1...

Embodiment 2

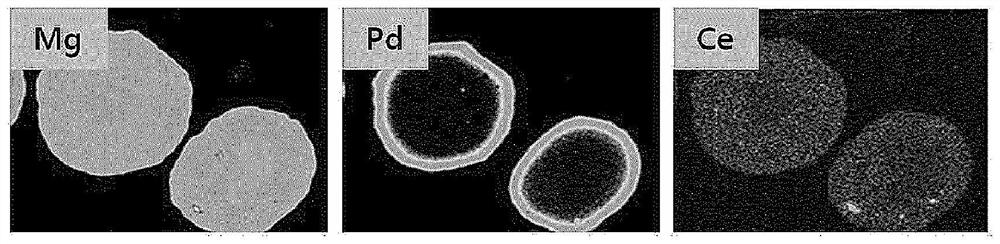

[0034] In Example 2, a magnesium-palladium complex other than cerium was used, and the composition of magnesium and palladium was the same as in Example 1.

Embodiment 3

[0036] In Example 3, a catalyst was produced in the same manner as in Example 1, except that the content of cerium oxide after firing was 2.0% based on the overall weight. Similar to Example 1, magnesium and cerium are uniformly distributed inside the carrier, while palladium is mainly distributed in a thickness of 20 μm at a certain distance from the outer contour of the carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com