Titanium dioxide nano composite material as well as preparation method and application thereof

A nanocomposite material, titanium dioxide technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of battery cycle stability and rate performance to be improved, achieve good application prospects, excellent cycle stability and rate performance, make up for The effect of poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

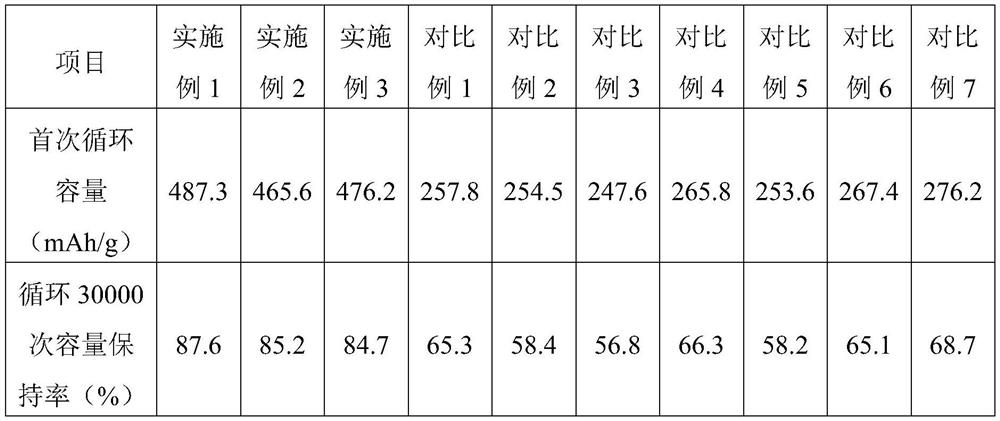

Examples

Embodiment 1

[0025] (1) Add NaOH solution (0.5mol / L) dropwise to 25mL ruthenium chloride hydrate solution (0.4mol / L) and stir continuously, adjust the pH to 7, wash once with 10mL NaCl solution (0.6mol / L), After drying, hydrated ruthenium dioxide powder is obtained;

[0026] (2) the ruthenium dioxide hydrate powder is mixed with activated carbon, then polyvinyl alcohol is added and mixed evenly, the mass ratio of ruthenium dioxide hydrate powder, activated carbon and polyvinyl alcohol is 6:4:2, and the ruthenium oxide-activated carbon composite material is obtained;

[0027] (3) Ruthenium oxide-activated carbon composite material is dispersed in dehydrated alcohol, adds titanium sulfate in batches, the mass volume ratio of ruthenium oxide-activated carbon composite material, dehydrated alcohol and titanium sulfate is 5.5g:24mL:6g, for the first time Add 1 / 4 of the total mass of titanium sulfate, stir for 10 minutes, add the remaining titanium sulfate for the second time, stir for 15 minute...

Embodiment 2

[0029] (1) Add NaOH solution (0.4mol / L) dropwise to 30mL ruthenium chloride hydrate solution (0.3mol / L) and stir continuously, adjust the pH to 7, wash once with 5mL NaCl solution (0.5mol / L), After drying, hydrated ruthenium dioxide powder is obtained;

[0030] (2) Mix hydrated ruthenium dioxide powder with activated carbon, then add polytetrafluoroethylene and mix evenly, the mass ratio of hydrated ruthenium dioxide powder, activated carbon and polytetrafluoroethylene is 5:5:1 to obtain ruthenium oxide-activated carbon composite Material;

[0031] (3) ruthenium oxide-activated carbon composite material is dispersed in dehydrated alcohol, adds titanium isopropoxide in batches, the mass volume ratio of ruthenium oxide-activated carbon composite material, dehydrated alcohol and titanium isopropoxide is 5g:30mL:4g, Add 1 / 4 of the total mass of titanium isopropoxide for the first time, stir for 15 minutes, add the rest of titanium isopropoxide for the second time, stir for 20 min...

Embodiment 3

[0033] (1) Add NaOH solution (0.6mol / L) dropwise to 25mL of ruthenium chloride hydrate solution (0.5mol / L) and stir continuously, adjust the pH to 7, wash twice with 15mL of NaCl solution (0.8mol / L), After drying, hydrated ruthenium dioxide powder is obtained;

[0034] (2) hydrated ruthenium dioxide powder is mixed with activated carbon, then add sodium carboxymethyl cellulose, the mass ratio of hydrated ruthenium dioxide powder, activated carbon and sodium carboxymethyl cellulose is 8:3:2, obtains ruthenium oxide- Activated carbon composite materials;

[0035] (3) The ruthenium oxide-activated carbon composite material is dispersed in absolute ethanol, and titanyl difluoride is added in batches, the mass volume ratio of ruthenium oxide-activated carbon composite material, dehydrated alcohol and titanyl difluoride is 6g:20mL:8g, Add 1 / 4 of the total mass of titanyl oxyfluoride for the first time, stir for 12 minutes, add the remaining titanyl oxyfluoride for the second time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com