Method for detecting content of each component in scale on surface of hot-rolled strip steel

A technology for surface oxidation and hot rolling of strip steel, which is applied in chemical method analysis, measuring device, preparation of test samples, etc., to facilitate corrosion and observation, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

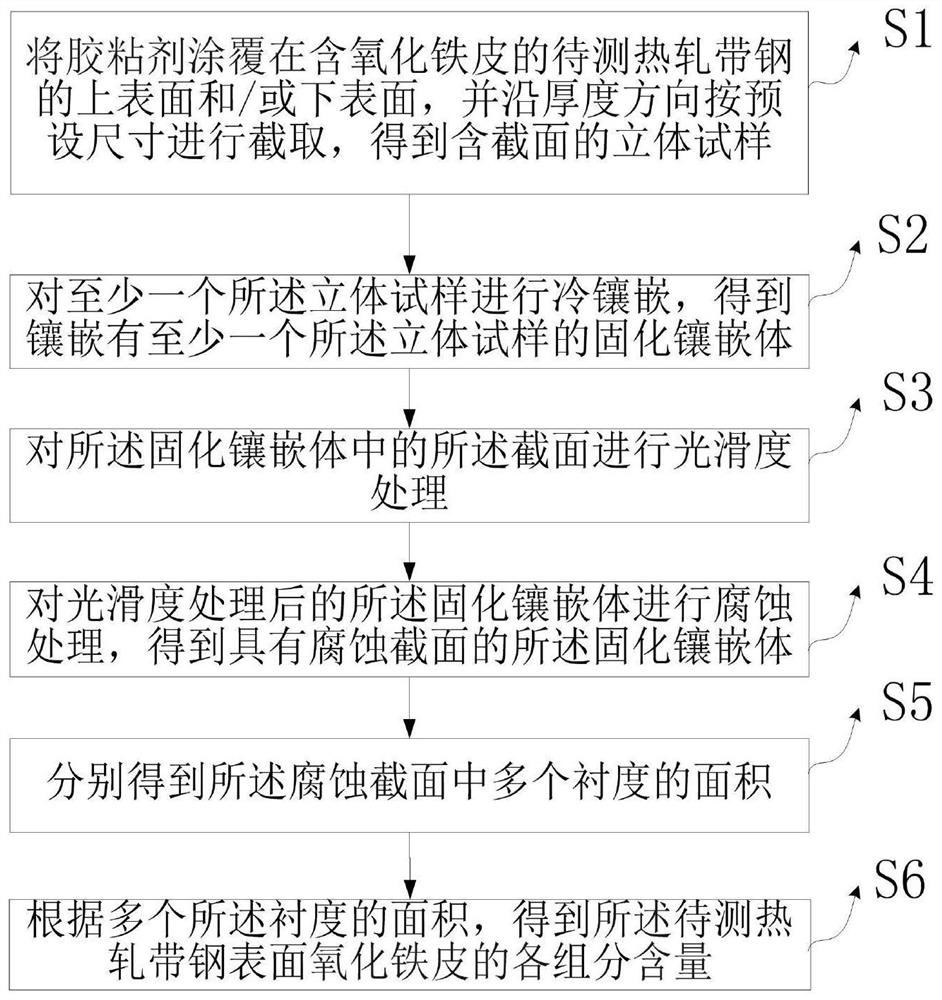

[0060] The invention provides a method for detecting the content of each component in the oxide scale on the surface of hot-rolled strip steel, the specific steps are as follows:

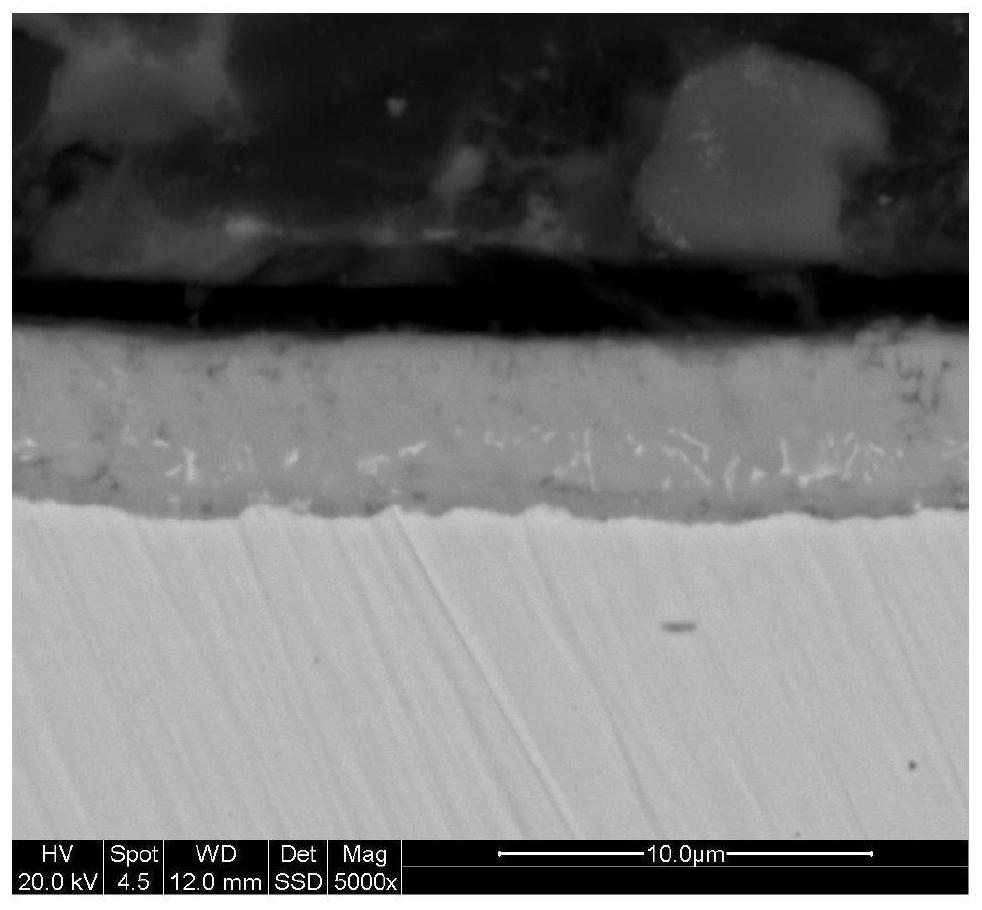

[0061] First, apply epoxy resin glue on the surface of the sample, and place it horizontally for 36 hours. After the surface glue is completely solidified, use a grinder to process the sample cross-section to reduce scratches on the cross-section during the preparation process, and use epoxy resin for cold mounting. The time is 24 hours, when the thickness of the iron sheet is 5 μm, the inlay with an angle is adopted, the sample and the inlay surface form an acute angle, and the angle range is 15°.

[0062] Grind the specimen section on sandpaper. First, use 220-grain SIC sandpaper for initial grinding to remove scratches on the cross-section of the sample. The grinding time is 20 minutes. The rougher the cross-section, the longer the grinding time. Secondly, use 320-grit SIC sandpaper to remove th...

Embodiment 2

[0065] The invention provides a method for detecting the content of each component in the oxide scale on the surface of hot-rolled strip steel, the specific steps are as follows:

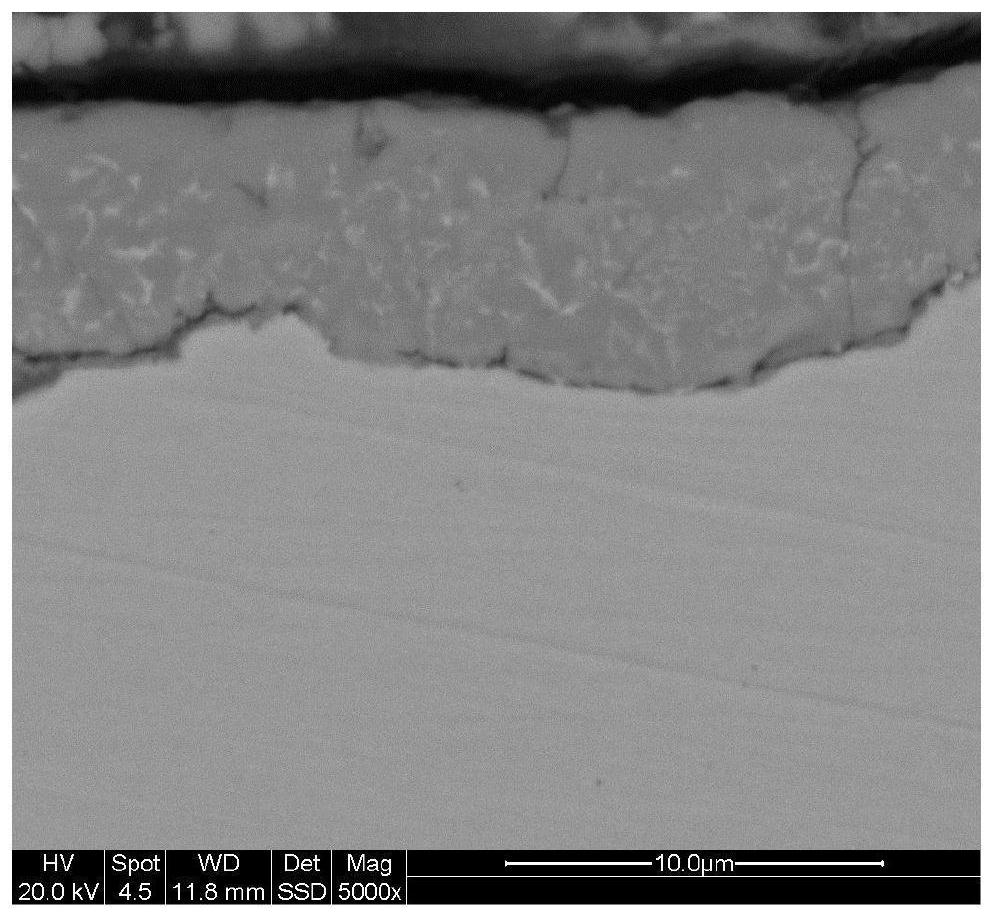

[0066] First, apply epoxy resin glue on the surface of the sample, and place it horizontally for 40 hours. After the surface glue is completely solidified, use a grinder to process the sample section to reduce the scratches of the section during the preparation process; use epoxy resin for cold mounting, inlaying The time is 36 hours, and when the thickness of the iron sheet is 10 μm, the sample is mounted horizontally, and there is no need to cold mount the sample section with an angle.

[0067] Grind the specimen section on sandpaper. First, use 220-grain SIC sandpaper for initial grinding to remove scratches on the cross-section of the sample. The grinding time is 30 minutes. The rougher the cross-section, the longer the grinding time. Secondly, use 320-grit SIC sandpaper to remove the scratches...

Embodiment 3

[0070] The invention provides a method for detecting the content of each component in the oxide scale on the surface of hot-rolled strip steel, the specific steps are as follows:

[0071] First, apply epoxy resin glue on the surface of the sample, and place it horizontally for 48 hours. After the surface glue is completely solidified, use a grinder to process the sample section to reduce scratches on the section during the preparation process, and use epoxy resin for cold mounting. The time is 48 hours, when the iron sheet is 4 μm, it is necessary to use an angled inlay, the sample and the inlay surface form an acute angle, and the angle range is 45°.

[0072] Grind the specimen section on sandpaper. First, use 220-grain SIC sandpaper for initial grinding to remove scratches on the cross-section of the sample. The grinding time is 40 minutes. The rougher the cross-section, the longer the grinding time. Secondly, use 320-grit SIC sandpaper to remove the scratches caused by rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com