Al-free medical zinc-based alloy dendrite corrosion reagent and preparation method and use method thereof

A zinc alloy and reagent technology, which is applied in the field of metallographic analysis of as-cast zinc alloys, can solve problems such as difficulty in in-depth analysis of microstructures, inability to accurately display the fine structure and morphology of Al-free medical zinc alloys, and achieve in-depth analysis and analysis. Convenient characterization, improved fine tissue morphology, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

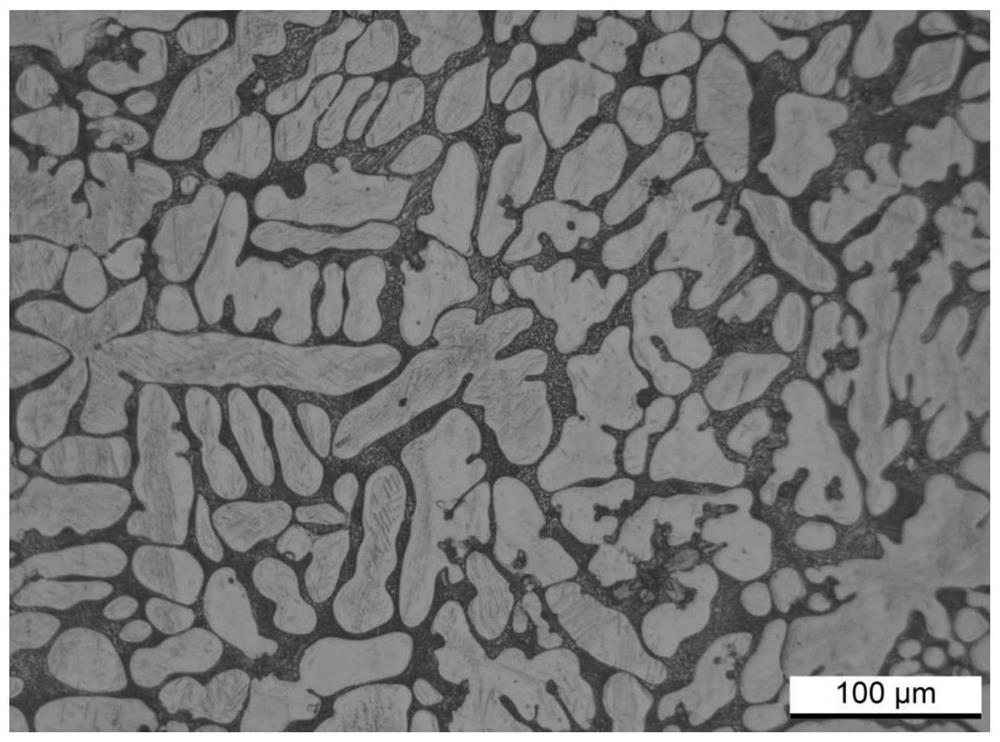

[0044] The metallographic preparation of the medical Zn-1Mg-0.25Nd-1.2Sn zinc alloy dendrites in Example 1 is specifically obtained by the following steps:

[0045] Step 1: First add 57.5ml of deionized water to the container, then add 3.5g of citric acid and 4.4g of picric acid in sequence, and stir for 30 circles in forward / counterclockwise directions, until the solid particles are completely dissolved to obtain a mixed solution with uniform components.

[0046] Step 2: Immediately after adding 2.5ml of glacial acetic acid and 40ml of absolute ethanol to the mixed solution described in step 1, after stirring evenly, let it stand for 3 minutes to complete the preparation of the corrosion reagent.

[0047] The specific process of applying the zinc alloy dendrite corrosion reagent of this embodiment to the cast Zn-1Mg-0.25Nd-1.2Sn zinc alloy is:

[0048] First, the zinc alloy in Example 1 is ground for 8 seconds at a speed of 2800 to 3000 r / min with multiple sandpapers of 1000# a...

Embodiment 2

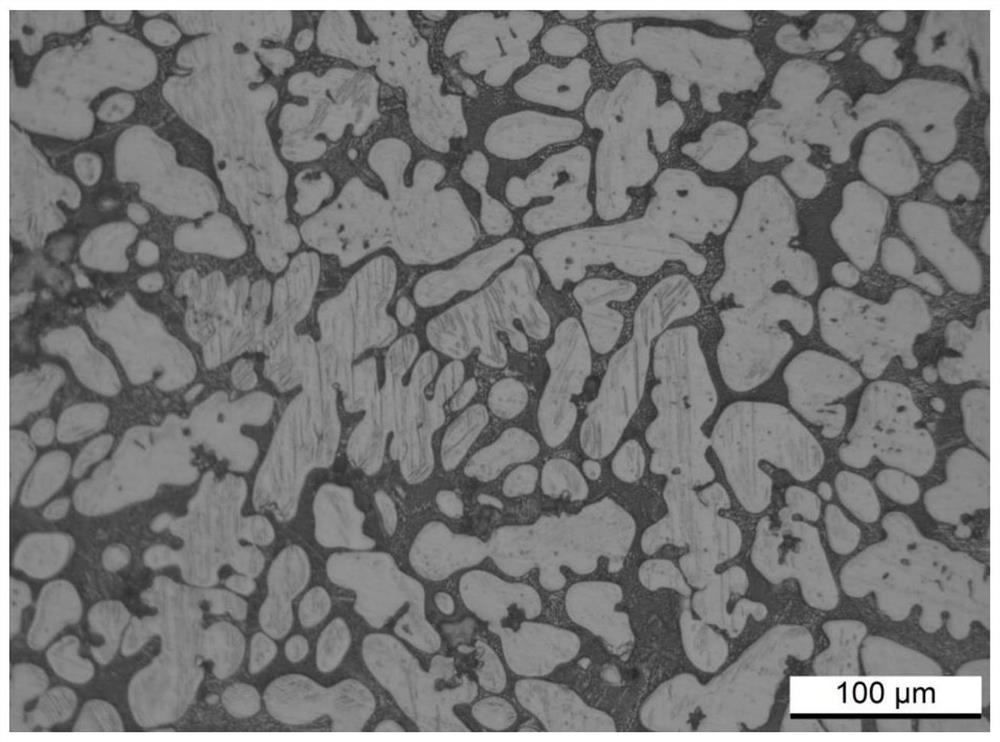

[0051] The medical Zn-1Mg-0.25Sn-1.5Cu zinc alloy dendrite metallographic preparation of the present embodiment 2 is specifically obtained by the following steps:

[0052] Step 1: First add 54ml of deionized water into the container, then add 4.1g of citric acid and 4.5g of picric acid in sequence, and stir for 30 circles in forward / counterclockwise direction, until the solid particles are completely dissolved to obtain a mixed solution with uniform components.

[0053] Step 2: Immediately after adding 2.5ml of glacial acetic acid and 43.5ml of absolute ethanol to the mixed solution described in step 1, after stirring evenly, let it stand for 3 minutes to complete the preparation of the corrosion reagent.

[0054] The specific process of applying the zinc alloy dendrite corrosion reagent of this embodiment to the cast Zn-1Mg-0.25Nd-1.5Cu zinc alloy is:

[0055] First, the zinc alloy in Example 2 is ground for 7 seconds at a speed of 2800 to 3000 r / min with 1000# and 2000# mult...

Embodiment 3

[0057] The medical Zn-1Mg-0.25Nd-3Cu zinc alloy dendrite metallographic preparation of the present embodiment 3 is specifically obtained by the following steps:

[0058] Step 1: First add 53ml of deionized water into the container, then add 4.4g of citric acid and 4.8g of picric acid in sequence, stir for 30 circles in the forward / counterclockwise direction, and obtain a mixed solution with uniform components after the solid particles are completely dissolved.

[0059] Step 2: Immediately after adding 3ml of glacial acetic acid and 44ml of absolute ethanol to the mixed solution described in step 1, after stirring evenly, let it stand for 3 minutes to complete the preparation of the corrosion reagent.

[0060] The specific process of applying the zinc alloy dendrite corrosion reagent of the present embodiment to the cast Zn-1Mg-0.25Nd-3Cu zinc alloy is as follows:

[0061] First, the zinc alloy in Example 3 is ground for 10s at a speed of 2800-3000r / min with 1000#, 2000# multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com