Cationic dyeable antistatic polyester wool top and preparation method thereof

An anti-static, cationic technology, applied in conductive/anti-static filament manufacturing, rayon manufacturing, single-component polyester rayon, etc., can solve the problems of complex process, inflexibility, long process, etc. Simple, favorable charge dissipation, excellent hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

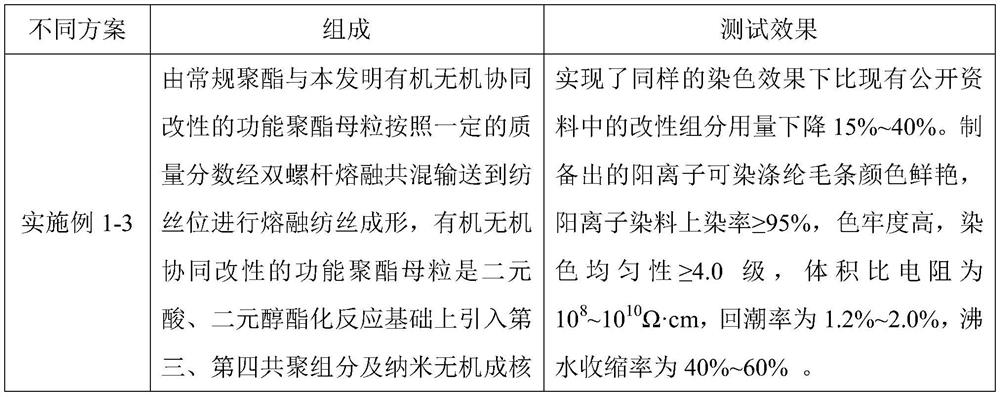

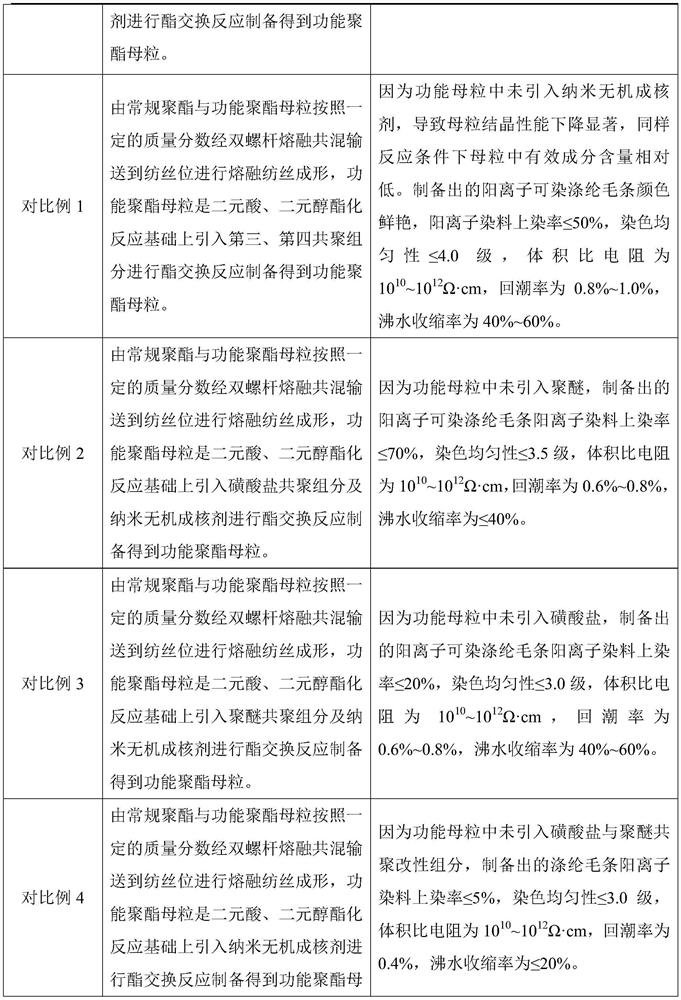

Examples

Embodiment 1

[0048] A preparation method for cationic dyeable antistatic polyester wool top, comprising the following steps:

[0049] Step (1), organic-inorganic synergistically modified functional polyester masterbatch:

[0050] After mixing dibasic alcohol and dibasic acid, adding titanium series composite catalyst, heat stabilizer and antioxidant, and then carrying out esterification reaction. The esterification product obtained by the esterification reaction, the nano-inorganic nucleating agent and the modified copolymerization component are mixed and then subjected to a polycondensation reaction to obtain organic and inorganic synergistically modified functional polyester masterbatches.

[0051] Wherein the modified copolymerization component includes sodium bis-isophthalate sulfonate and long carbon chain polyethylene glycol, bis-isophthalate sodium sulfonate is the third monomer, long-carbon chain polyethylene glycol Alcohol is the fourth monomer. The nano-inorganic nucleating age...

Embodiment 2

[0070] A preparation method for cationic dyeable antistatic polyester wool top, comprising the following steps:

[0071] Step (1), organic-inorganic synergistically modified functional polyester masterbatch:

[0072] After mixing dibasic alcohol and dibasic acid, adding titanium series composite catalyst, heat stabilizer and antioxidant, and then carrying out esterification reaction. The esterification product obtained by the esterification reaction, the nano-inorganic nucleating agent and the modified copolymerization component are mixed and then subjected to a polycondensation reaction to obtain organic and inorganic synergistically modified functional polyester masterbatches.

[0073] Wherein the modified copolymerization component includes sodium bis-isophthalate sulfonate and long carbon chain polyethylene glycol, bis-isophthalate sodium sulfonate is the third monomer, long-carbon chain polyethylene glycol Alcohol is the fourth monomer. The nano-inorganic nucleating age...

Embodiment 3

[0092] A preparation method for cationic dyeable antistatic polyester wool top, comprising the following steps:

[0093] Step (1), organic-inorganic synergistically modified functional polyester masterbatch:

[0094] After mixing dibasic alcohol and dibasic acid, adding titanium series composite catalyst, heat stabilizer and antioxidant, and then carrying out esterification reaction. The esterification product obtained by the esterification reaction, the nano-inorganic nucleating agent and the modified copolymerization component are mixed and then subjected to a polycondensation reaction to obtain organic and inorganic synergistically modified functional polyester masterbatches.

[0095] Wherein the modified copolymerization component includes sodium bis-isophthalate sulfonate and long carbon chain polyethylene glycol, bis-isophthalate sodium sulfonate is the third monomer, long-carbon chain polyethylene glycol Alcohol is the fourth monomer. The nano-inorganic nucleating age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com