Preparation method and application of self-supporting electrode

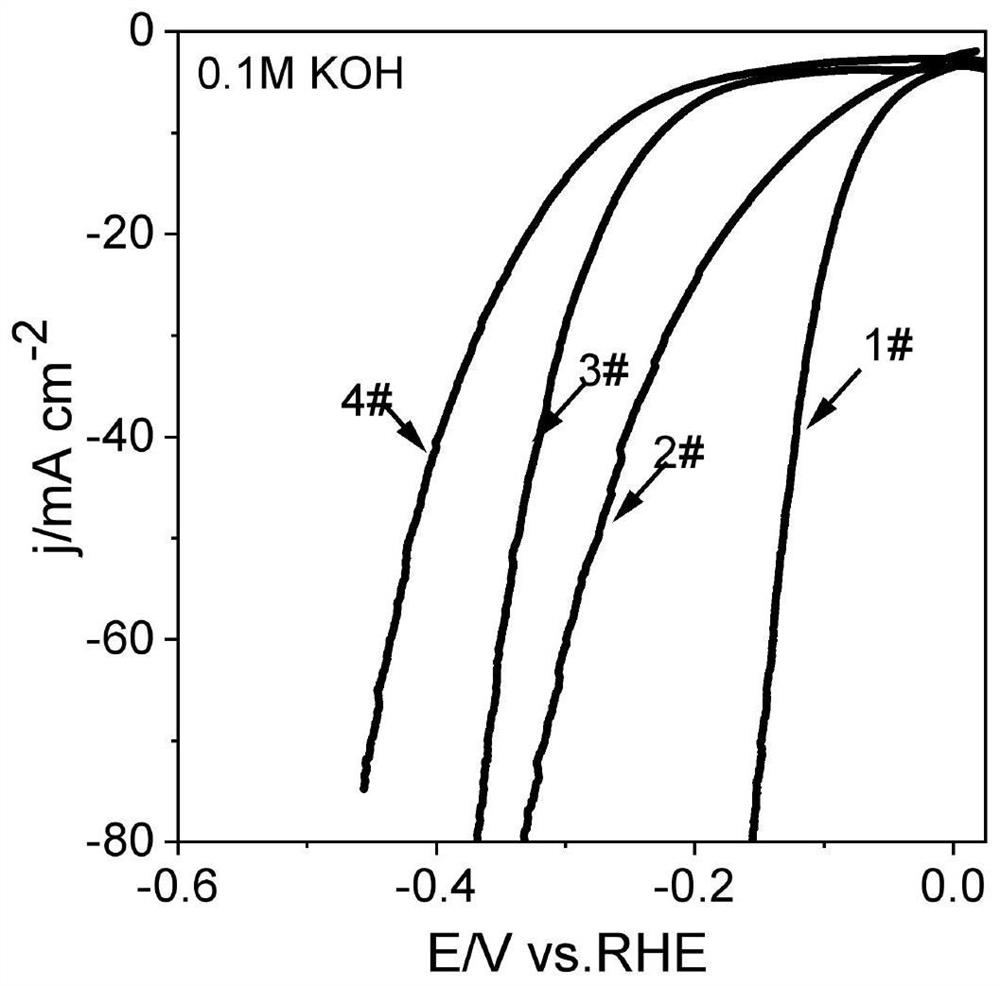

A self-supporting electrode and supporting material technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor stability and high cost, and achieve the effect of saving energy, improving electrocatalytic performance, and reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Copper foam self-supporting electrode supported by HHTP modified basic cobalt carbonate (HHTP-Co(OH) 2 CO3 / CF) preparation method, specifically comprises the following steps:

[0037] The first step, Co(OH) 2 CO 3 The synthesis method of / CF: Add 1cm × 2cm foam copper and 4mL solution in the reaction kettle, seal the reaction kettle for 12 hours of hydrothermal reaction at 95°C, the solution is a mixed solution of 0.6M urea and 0.3M cobalt nitrate, wait for the temperature After naturally cooling down to room temperature, the carrier material was taken out, rinsed with deionized water, and dried under vacuum at 50°C for 8-16 hours.

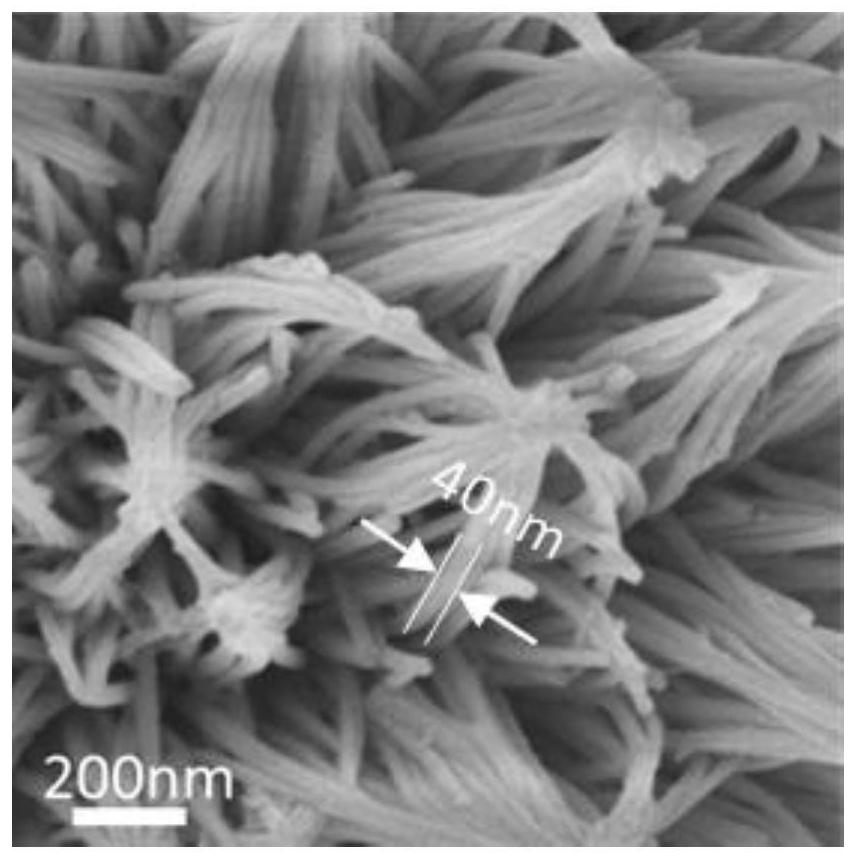

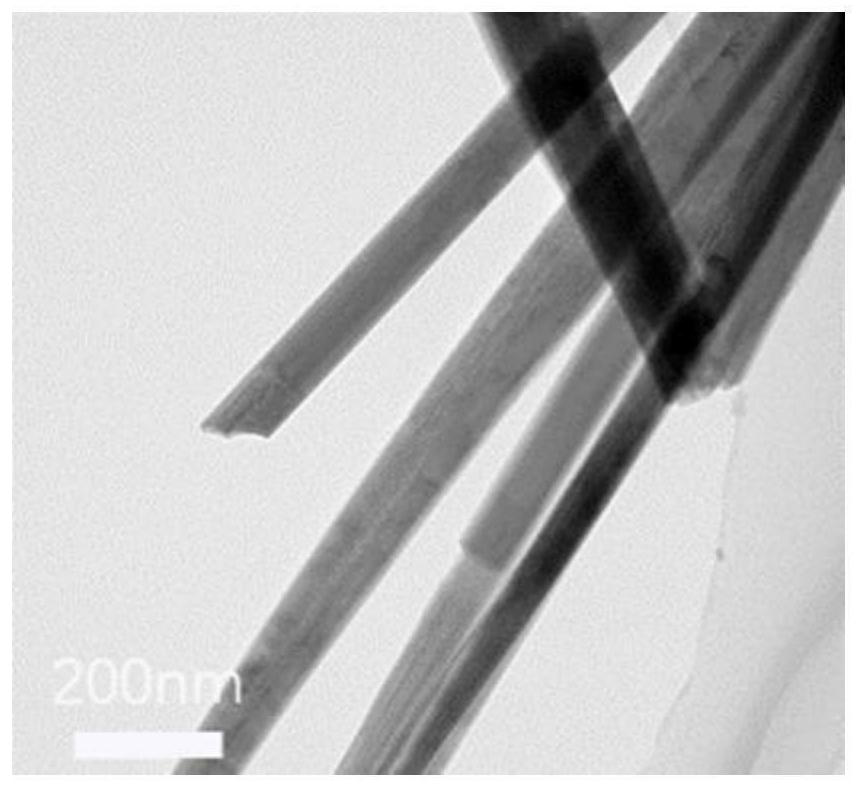

[0038] The second step, HHTP-Co(OH) 2 CO 3 The synthesis method of / CF: add 3~5ml deionized water and 7mg HHTP into the reaction kettle, add 0.18ml NMP, and ultrasonicate for 20~30min under the condition of 100Hz until the mixture is uniform to form a dark solution, and the carrier after the first step reaction Immerse in the dark sol...

Embodiment 2

[0042] Copper foam self-supporting electrode supported by HOB modified basic cobalt carbonate (HOB-Co(OH) 2 CO 3 / CF) preparation method, specifically comprises the following steps:

[0043] The first step, Co(OH) 2 CO 3 The synthesis method of / CF: Add 2cm × 2cm foam copper and 4mL solution in the reaction kettle, seal the reaction kettle 120 ℃ hydrothermal reaction for 6 hours, the solution is a mixed solution of 0.6M urea and 0.3M cobalt nitrate, wait for the temperature After naturally cooling down to room temperature, the carrier material was taken out, rinsed with deionized water, and dried under vacuum at 50°C for 8 hours.

[0044] The second step, HOB-Co(OH) 2 CO 3 The synthesis method of / CF: add 5mg of HOB, 4ml of deionized water and 0.165mL of NMP into the reaction kettle, dissolve it by ultrasonication for 10min, and then add a piece of Co(OH) with a size of 1cm × 2cm 2 CO 3 / CF, a sealed reaction vessel was hydrothermally reacted at 120°C for 12 hours, and ...

Embodiment 3

[0046] HHTP-modified basic nickel-cobalt carbonate supported carbon cloth self-supporting electrode (HHTP-NiCo(OH) 2 CO 3 / CC) preparation method, specifically comprises the following steps:

[0047] The first step, NiCo(OH) 2 CO 3 Synthesis method of / CC: Add 0.5cm × 0.5cm hydrophilic carbon cloth and 1 mL solution in the reactor, seal the reactor at 95°C for 12 hours, the solution is 0.6M urea, 0.1M cobalt nitrate, 0.1M nickel nitrate mixed solution, after the temperature naturally dropped to room temperature, the carrier material was taken out, rinsed with deionized water, and dried under vacuum at 50°C for 8h.

[0048] The second step, HHTP-NiCo(OH) 2 CO 3 The synthesis method of / CC: add 1mg of HHTP, 4ml of deionized water and 0.165mL of NMP into the reaction kettle, dissolve it by ultrasonication for 30min, and then add a piece of NiCo(OH) with a size of 0.5cm × 0.5cm 2 CO 3 / CC, hydrothermal reaction at 85°C in a sealed reaction vessel for 24 hours, after cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com