Self-healing anti-pollution flashover coating as well as preparation method and application thereof

An anti-pollution flashover coating and self-healing technology, applied in coatings and other directions, can solve the problems of unstable anti-pollution flashover performance, mechanical wear of coatings, electrical equipment failures, etc., and achieve improved anti-pollution flashover performance and excellent coatings. Service life, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

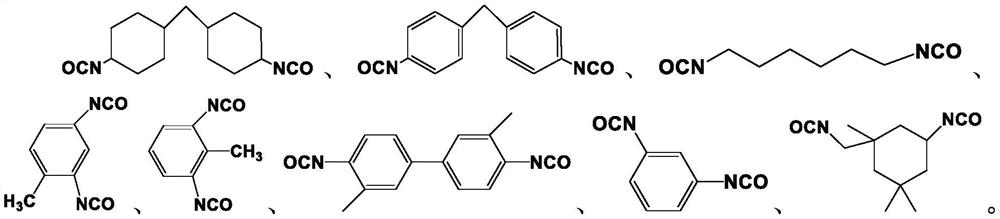

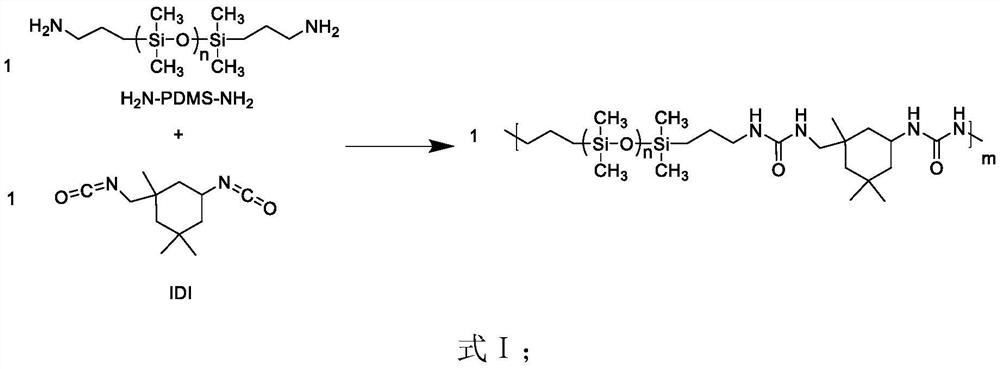

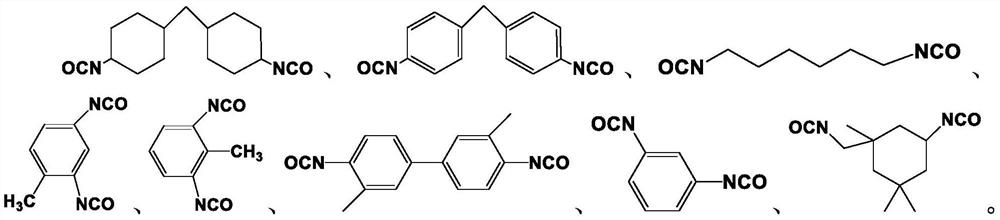

Method used

Image

Examples

Embodiment 1

[0034] A self-healing antifouling flashover coating comprising diamine-containing polydimethylsilane (CAS No.: 106214-84-0, molecular weight 3000), 1,3,3-trimethyl-5-isocyanato -A combination of 1-isocyanatomethylcyclohexane and polydimethylsilane (CAS No.: 63148-62-9, 100cSt / 25°C); among them, diamine-containing polydimethylsilane and 1,3 , The molar ratio of 3-trimethyl-5-isocyanato-1-isocyanatomethylcyclohexane is 1:1, the mass ratio of diamine-containing polydimethylsilane and polydimethylsilane 1:1;

[0035]The preparation method of the self-healing antifouling flashover coating provided in this embodiment comprises: polydimethylsilane, 1,3,3-trimethyl-5-isocyanato-1-isocyanatomethylcyclohexyl Alkane and polydimethylsilane were dissolved in tetrahydrofuran and reacted for 50 hours to obtain the tetrahydrofuran.

Embodiment 2

[0037] A self-healing antifouling flashover coating comprising diamine-containing polydimethylsilane (CAS No.: 106214-84-0, molecular weight 3000), 4,4'-methylenebis(phenylisocyanate) and poly(dimethylsiloxane-co-methylphenylsiloxane) (CAS No.: 63148-58-3, ~100mPa.s / 25°C); among them, diamine-containing polydimethylsilane and 4,4′-Methylenebis(phenylisocyanate) in a molar ratio of 1:0.98, diamine-containing polydimethylsilane and poly(dimethylsiloxane-co-methylphenylsiloxane The mass ratio of alkane) is 1:2.5;

[0038] The preparation method of the self-healing antifouling flashover coating provided in this embodiment comprises: polydimethylsilane, 4,4'-methylenebis(phenylisocyanate) and poly(dimethylsiloxane- co-methylphenylsiloxane) was dissolved in tetrahydrofuran and reacted for 48 hours to obtain the tetrahydrofuran.

Embodiment 3

[0040] A self-healing antifouling flashover coating, comprising diamine-containing polydimethylsilane (CAS No.: 106214-84-0, molecular weight 5000), 4,4'-HMDI, 1,1'-methylene bis( 4-isocyanatocyclohexane) and poly(dimethylsiloxane-co-methylphenylsiloxane) (CAS No.: 63148-58-3, ~100mPa.s / 25°C); among them, The molar ratio of diamine-containing polydimethylsilane to 4,4'-HMDI, 1,1'-methylenebis(4-isocyanatocyclohexane) is 1:1.05, and the diamine-containing polydimethylsilane The molar ratio of methylsilane and poly(dimethylsiloxane-co-methylphenylsiloxane) is 1:5;

[0041] The preparation method of the self-healing anti-fouling flashover coating provided in this embodiment comprises: polydimethylsilane, 4,4'-HMDI, 1,1'-methylenebis(4-isocyanatocyclohexane) and poly(dimethylsiloxane-co-methylphenylsiloxane) were dissolved in tetrahydrofuran, and reacted for 72 hours to obtain the tetrahydrofuran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com