Water-based mirror back paint and processing technology thereof

A processing technology and technology of mirror back paint, which is applied in the field of water-based mirror back paint and its processing technology, can solve the problems of poor film formation, poor crack resistance, and poor internal crosslinking, and achieve good gloss and water resistance, and enhance mechanical properties Ability, effect of inhibiting pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

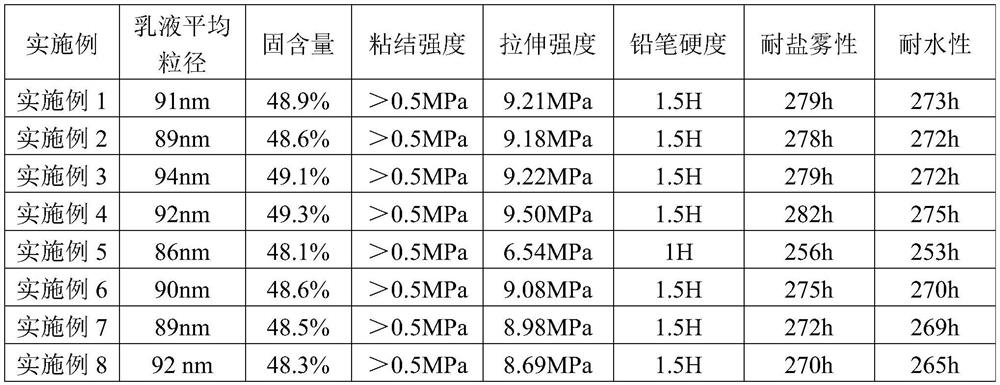

Examples

Embodiment 1

[0036] Step 1: (1) ultrasonically disperse carbon nanotubes in sodium dodecylbenzene sulfonate solution, add sodium bicarbonate, DNS-86, and ultrasonically mix evenly; add deionized water to dilute and homogenize; obtain an emulsifier Solution A. Add butyl acrylate and styrene to emulsifier solution A at a mass ratio of 38:62, set the temperature at 60°C for pre-emulsification for 2 hours, and obtain a nuclear solution; (2) Dimethylaminoethyl methacrylate, 3 - Add isopropyl-dimethylbenzyl isocyanate to the EF-800 solution and mix well; add deionized water to dilute and homogenize; obtain emulsifier solution B. Add butyl acrylate and styrene to emulsifier solution B at a mass ratio of 56:44, set the temperature at 50°C for pre-emulsification for 2 hours to obtain a shell solution; (3) mix one-third of the core solution with three One of the potassium persulfate is mixed and added to the reactor, the reaction environment is replaced by nitrogen, an appropriate amount of pH buff...

Embodiment 2

[0041] Step 1: (1) ultrasonically disperse carbon nanotubes in sodium dodecylbenzene sulfonate solution, add sodium bicarbonate, DNS-86, and ultrasonically mix evenly; add deionized water to dilute and homogenize; obtain an emulsifier Solution A. Add butyl acrylate and styrene to emulsifier solution A at a mass ratio of 36:64, set the temperature at 50°C for pre-emulsification for 1 hour, and obtain a nuclear solution; (2) Dimethylaminoethyl methacrylate, 3 - Add isopropyl-dimethylbenzyl isocyanate to the EF-800 solution and mix well; add deionized water to dilute and homogenize; obtain emulsifier solution B. Add butyl acrylate and styrene to emulsifier solution B at a mass ratio of 55:45, set the temperature at 50°C for pre-emulsification for 1 hour, and obtain a shell solution; (3) mix one third of the core solution with three One of the potassium persulfate is mixed and added to the reactor, the reaction environment is replaced by nitrogen, an appropriate amount of pH buff...

Embodiment 3

[0046] Step 1: (1) ultrasonically disperse carbon nanotubes in sodium dodecylbenzene sulfonate solution, add sodium bicarbonate, DNS-86, and ultrasonically mix evenly; add deionized water to dilute and homogenize; obtain an emulsifier Solution A. Add butyl acrylate and styrene to emulsifier solution A at a mass ratio of 39:61, set the temperature at 70°C for pre-emulsification for 2 hours, and obtain a nuclear solution; (2) Dimethylaminoethyl methacrylate, 3 - Add isopropyl-dimethylbenzyl isocyanate to the EF-800 solution and mix well; add deionized water to dilute and homogenize; obtain emulsifier solution B. Add butyl acrylate and styrene to emulsifier solution B at a mass ratio of 58:42, set the temperature at 70°C for pre-emulsification for 2 hours to obtain a shell solution; (3) mix one-third of the core solution with three One of the potassium persulfate is mixed and added to the reactor, the reaction environment is replaced by nitrogen, an appropriate amount of pH buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com