Method and device system for purifying and recycling waste alcohol in high-carbon alcohol production

A technology of high-carbon alcohol and purification liquid, which is applied in the direction of separation methods, chemical instruments and methods, and the preparation of organic compounds, etc., to achieve the effects of increasing production, reducing emissions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

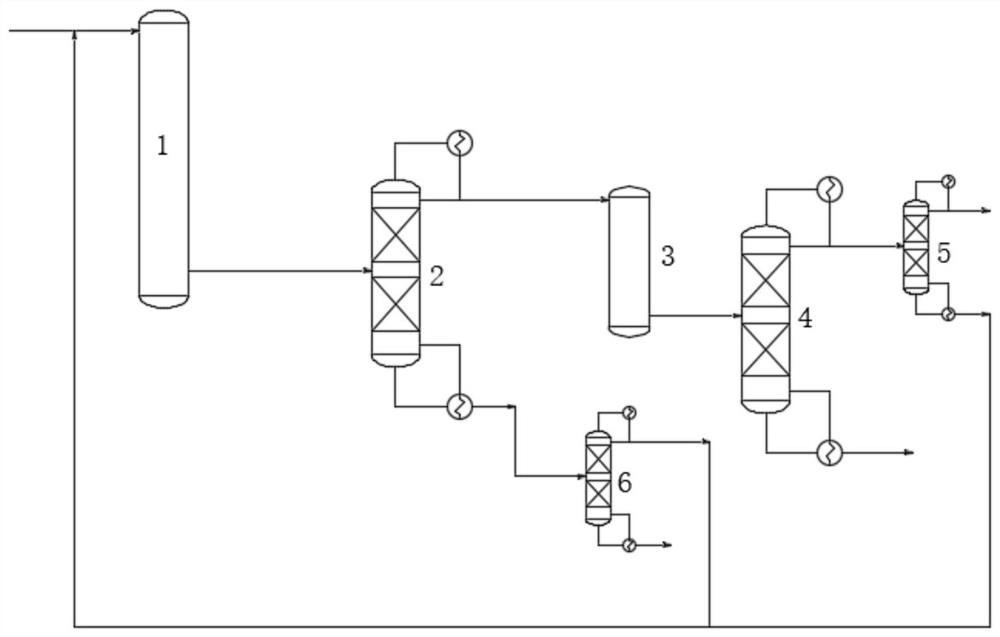

[0081] This embodiment provides a device system for a high carbonol purification reuse, such as figure 1 As shown, the device system includes a first rectification column 6, a second distillation column 5, and a hydrogenation unit, and a tower top discharge port of the first distillation column 6 connects a hydrogenation unit; the second fine The tower of the distillation column 5 is attached to the hydrogenation unit; the hydrogenation unit includes a first hydrogenation reactor 1, a third distillation column 2, a second hydrogenation reactor 3, which is sequentially connected in sequentially connected to the reaction feedstock. The fourth distillation column 4; the tower of the third rectification column 2 is connected to the feed port of the first distillation column 6; the top of the tower of the fourth distillation column 4 and the first The feed port of the dilutta 5; the top discharge port of the first distillation column 6 and the column discharge port of the second distil...

Embodiment 2

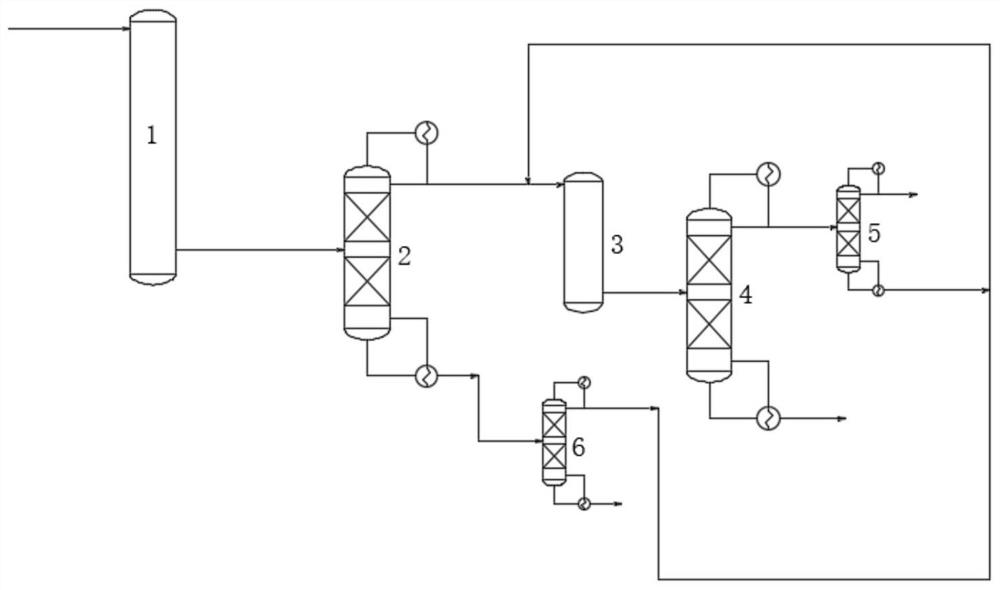

[0087] This embodiment provides a device system for a high carbonol purification reuse, such as figure 2 As shown, the device system includes a first rectification column 6, a second distillation column 5, and a hydrogenation unit, and a tower top discharge port of the first distillation column 6 connects a hydrogenation unit; the second fine The tower of the distillation column 5 is attached to the hydrogenation unit; the hydrogenation unit includes a first hydrogenation reactor 1, a third distillation column 2, a second hydrogenation reactor 3, which is sequentially connected in sequentially connected to the reaction feedstock. The fourth distillation column 4; the tower of the third rectification column 2 is connected to the feed port of the first distillation column 6; the top of the tower of the fourth distillation column 4 and the first The feed port of the secondary distillation column 5 is connected; the top of the first distillation column 6 and the tower of the second di...

Embodiment 3

[0093] This embodiment provides a method of performing high carbonol purification reuse using the device system provided in Example 1, the method comprising the steps of:

[0094] (1) The first mixture of 6000 kg / h of C10 aldehyde primary hydrogenated separation was pure in 7 kPa (underscore), 170 ° C, and the temperature of the colored condenser was 60 ° C to obtain a carbon atom. The number of organic matter having a 2-pH carbon atom is purified, and in the first mixture, 72% of the alcohol (including 50% 2-pH, 11.4) is included in the mass content. % 2-propyl heptenol, 6% C13 alcohol and 4.6% C15 alcohol), 2% 2-propyl hepthaldehyde and 26% ketones (including 11% C10 ketone, 6% C13 Ketone and 9% C15 ketone), wherein the content of 2-pH is 50%;

[0095] (2) The second mixture after the secondary hydrogenation separation is pure at 7 kPa (absolute pressure), 160 ° C. The temperature of the colored condenser is 60 ° C to obtain a carbon atom and 2-pH carbon. The second component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com