Antibacterial and antiviral mask and preparation method thereof

An anti-virus and mask technology, applied in biochemical fiber treatment, clothing, protective clothing, etc., can solve the problems of complex reaction process, limited load, poor bonding fastness, etc., and achieve high efficiency, durability, practicability, and washing resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

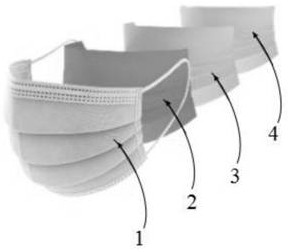

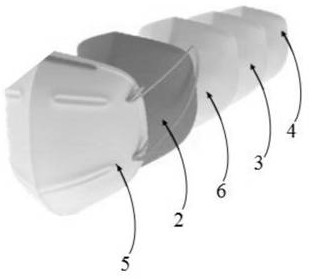

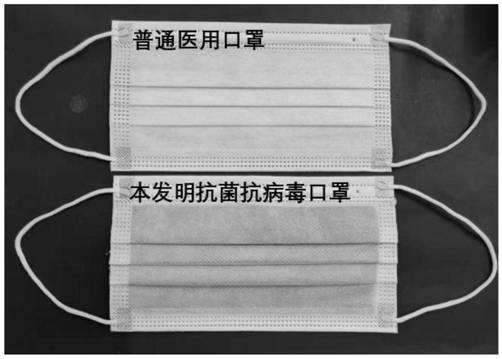

Image

Examples

preparation example Construction

[0045] Specifically, the preparation method of the melt-blown non-woven fabric modified by nano-cuprous oxide includes: sequentially immersing the melt-blown non-woven fabric in an alkaline solution, a copper source solution and a reducing solution, keeping the final dipping liquid rate of 10 % to 160%; and the melt-blown non-woven fabric after padding is arranged in a solvent reaction medium at 100° C. to 300° C., and reacted for 5s to 1800s to obtain a melt-blown non-woven fabric modified by nano-cuprous oxide. Preferably, the temperature of the solvent reaction medium is 140°C to 250°C, and the solvent reaction medium is ethylene glycol, glycerol, ethyl acetate, toluene, xylene, N,N-dimethylformamide, N,N- Dimethylacetamide, silicone oil, vegetable or animal oil.

[0046] Specifically, the relative content of copper atoms in the antibacterial and antiviral layer 2 is 1-18wt%, and the particle size of nano cuprous oxide is 20nm-300nm. The crystal form of the nano-cuprous ox...

Embodiment 1

[0066] Embodiment provides a kind of preparation method of antibacterial antibacterial mask, comprises the following steps:

[0067] S1, preparation of antibacterial and antiviral layer

[0068] S11, pretreatment of melt-blown non-woven fabric

[0069] Arrange the melt-blown non-woven fabric in sodium hydroxide solution for padding to obtain the pretreated melt-blown non-woven fabric; wherein, the impregnation temperature is 25°C, the time is 5s, and the melt-blown non-woven fabric after padding is Liquid carrying rate is 120%;

[0070] S12, pretreated melt-blown non-woven padding precursor solution

[0071] The pretreated melt-blown non-woven fabric is sequentially immersed in a 7% sodium hydroxide alkaline solution for 60 s, a 4% copper sulfate solution for 30 s, and a 4% glucose reduction solution for 300 s; the immersion temperature is 30°C, and the liquid-carrying rate of the melt-blown non-woven fabric after padding is 120%;

[0072] S13. In-situ synthesis of nano-cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com