Phytic acid-vanadium pentoxide composite material, preparation method thereof, electrode and battery

A technology of vanadium pentoxide and composite materials, which is applied in the field of phytic acid-vanadium pentoxide composite materials and its preparation, can solve problems such as difficulty in intercalation of zinc ions, poor structural stability, poor specific capacity and cycle performance, and achieve The effect of good rate conversion performance, performance improvement, and discharge specific capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

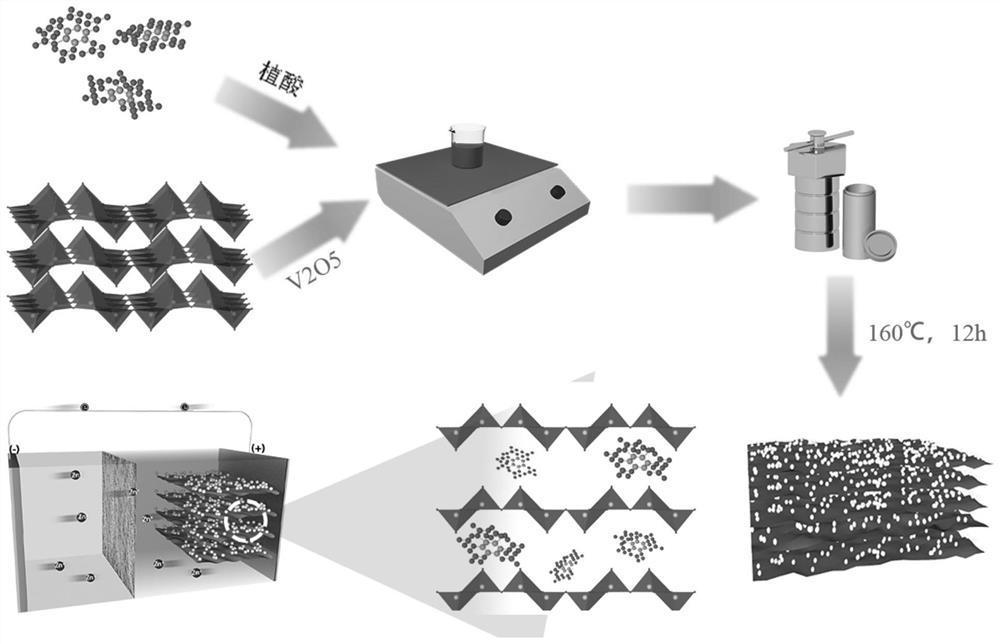

[0066] The present invention also proposes a phytic acid - preparing vanadium pentoxide composite material, the manufacturing method comprising the steps of:

[0067] Step (1): Mix the phytic acid, pentoxide, hydrogen peroxide, and water, stir to give a mixed solution;

[0068] Step (2): A hydrothermal reaction of the mixed solution obtained by step (1);

[0069] Step (3): After the hydrothermal reaction, centrifugation, washed, and dried to obtain the phytic acid - vanadium pentoxide composite.

[0070] Vanadium pentoxide feedstock with phytic acid embodiment of the present invention preferred embodiment, the molar ratio of phytic acid and vanadium pentoxide in step (1) is 0.02 to 0.3, i.e., when preparing the composite material of the present invention, employed the molar ratio of the raw materials; e.g., phytic acid molar ratio of vanadium pentoxide and may be 0.02,0.03,0.04,0.05,0.06,0.07,0.08,0.10,0.12,0.14,0.16,0.18,0.19,0.20,0.21,0.22 , 0.23,0.24,0.25,0.26,0.27,0.28,0.29 or...

Embodiment 1

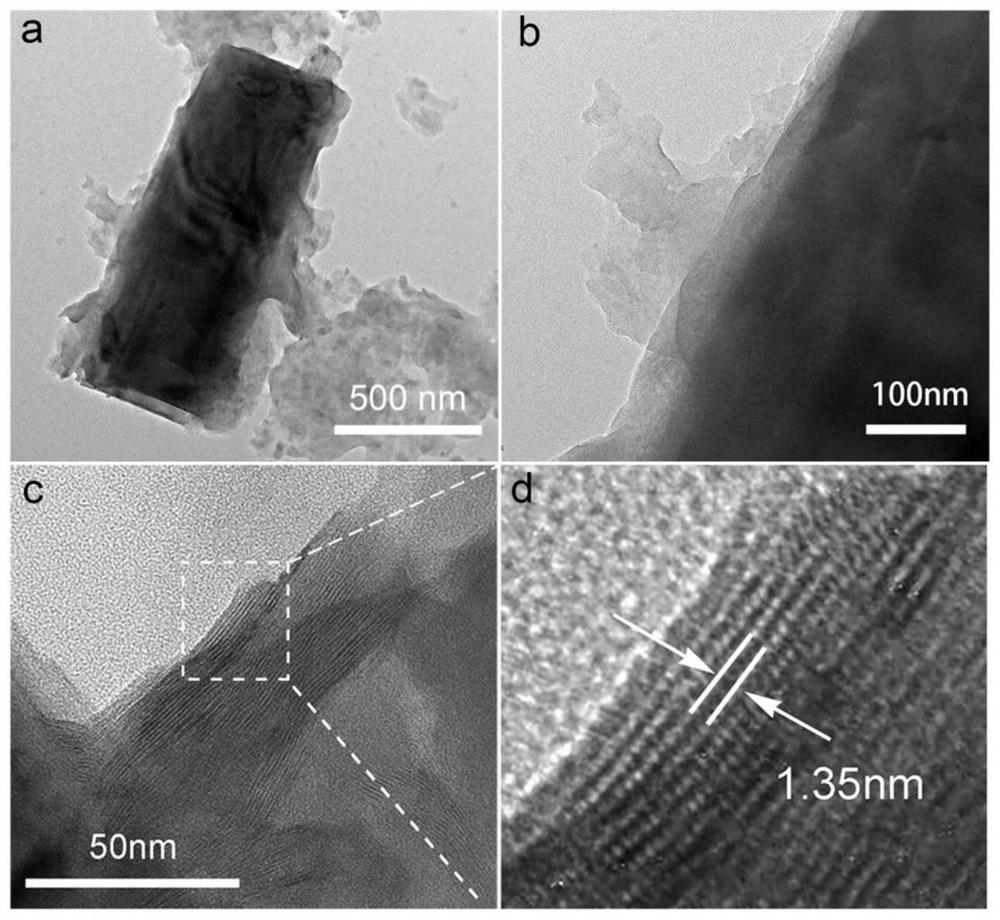

[0099] Phytocyanide-pentoxide composite, the raw material of the composite comprises phrochloric acid and vanadium dioxide; figure 1 As shown, in the composite material, the acidic acid is coated between the surface of the vanadium dioxide and inserted between adjacent layers of pentoxide (increased pentoxide layer spacing), and vanadium oxygen Structure of dioxide dioxide).

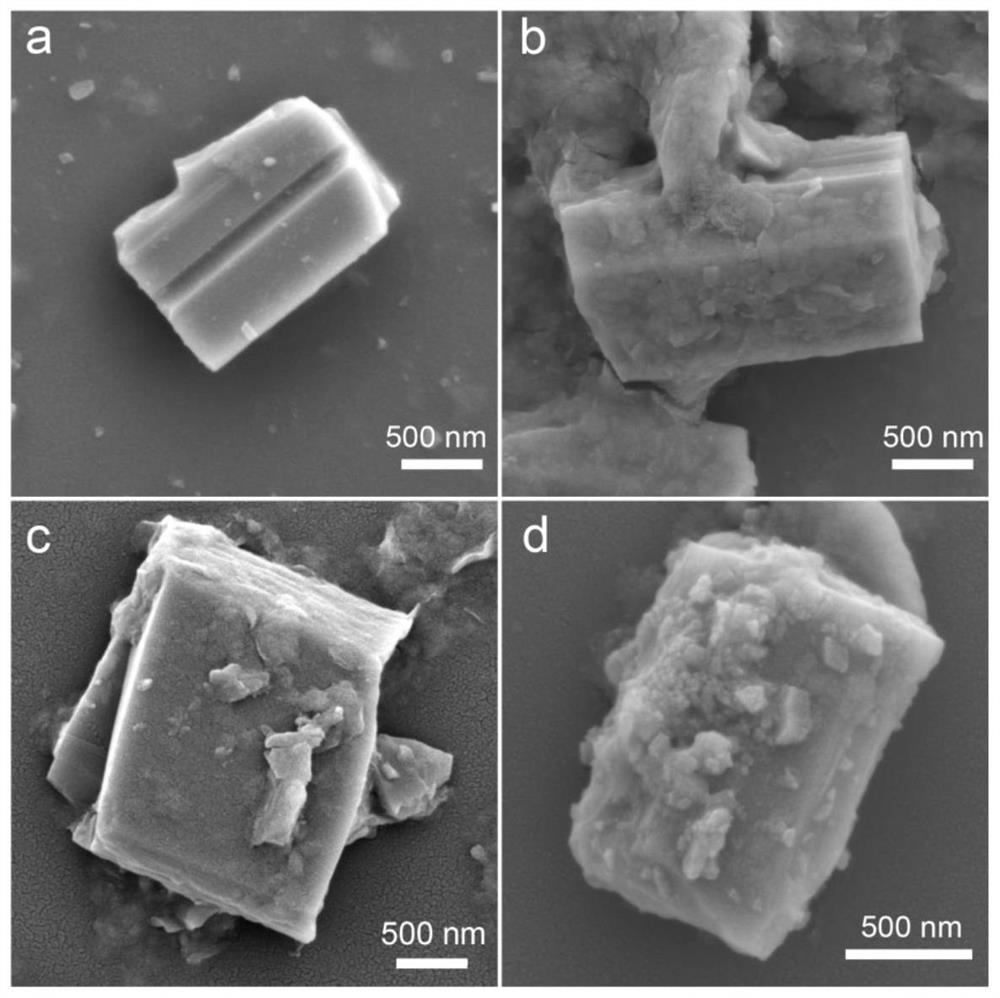

[0100] The phymic-pentoxide blend of the phytoside-pentoxide composite of the present embodiment is an organic product coating and a block layer material having a width of 0.8 to 1.1 μm, a length of 1 to 2 μm, an average thickness of 0.6 μm, and the surface of nano sheets is smooth. Neat figure 2 A shown). In the present embodiment, the amount of phytic acid incorporases (see the preparation method of the diofiltered boltide composite material below), and therefore there is less phytic acid coating.

[0101] The preparation method of the phytate-pentoxide blend of the present embodiment includes the followin...

Embodiment 2

[0113] The preparation method of the phytate-pentoxide blend of the present embodiment includes the following steps:

[0114](1) The pentoxide dioxide is stirred with a mixed solution consisting of a hydrogen peroxide solution and deionized water, and is recorded as a solution A; wherein the hydrogen peroxide solution and deionized water are 0.25, a hydrogen peroxide solution. The mass fraction of hydrogen peroxide is 35%; the stirring temperature is 25 ° C, the stirring time is 15 min; the concentration of the vanadium dioxide in the resulting solution A is 0.034 g / ml.

[0115] (2) The acid is dissolved in deionized water, stirred, and the aqueous acid solution is obtained, and it is recorded as a solution B; wherein the volume ratio of phytic acid and deionized water is 0.012, the stirring temperature is 25 ° C, and the stirring time is 5 min.

[0116] (3) The solution B was added dropwise to the solution A (the molar ratio of pentoxide diofedant vanadium and the amount of phy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com