Cold and heat preventing bridge joint for cantilever slab component and building with cold and heat preventing bridge joint

A technology of cantilever board and anti-cold, applied in the direction of building structure, building, building components, etc., can solve the problems of unavoidable thermal bridge, harmful environmental conditions of gypsum and paint, deterioration of buildings, etc., and achieve thermal break bridge structure of balcony Reasonable and practical, smooth transmission of bending moment and shear force, and reliable structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

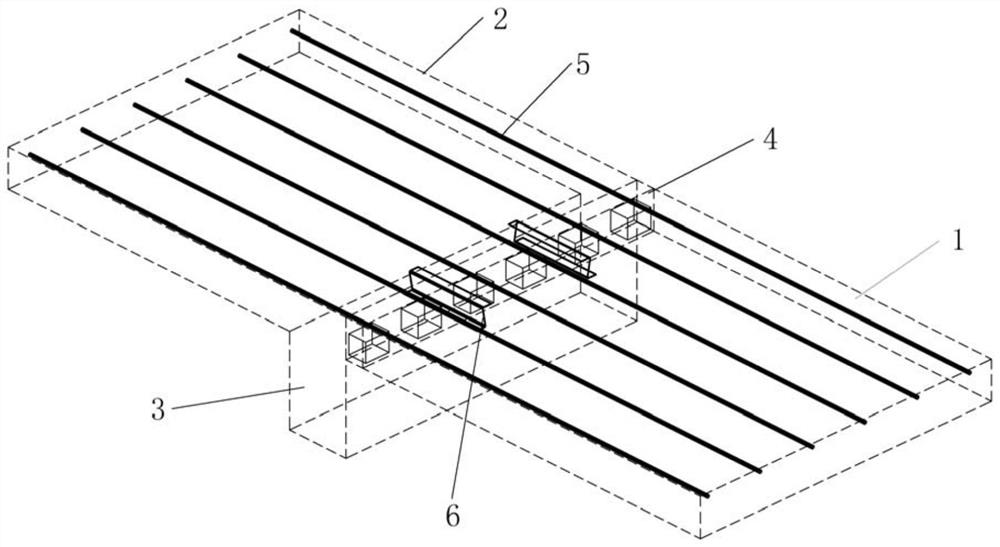

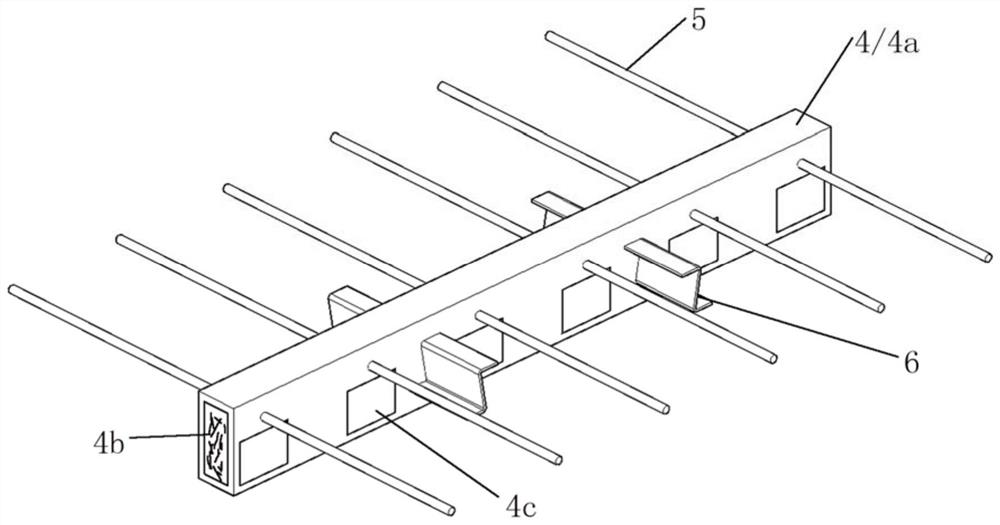

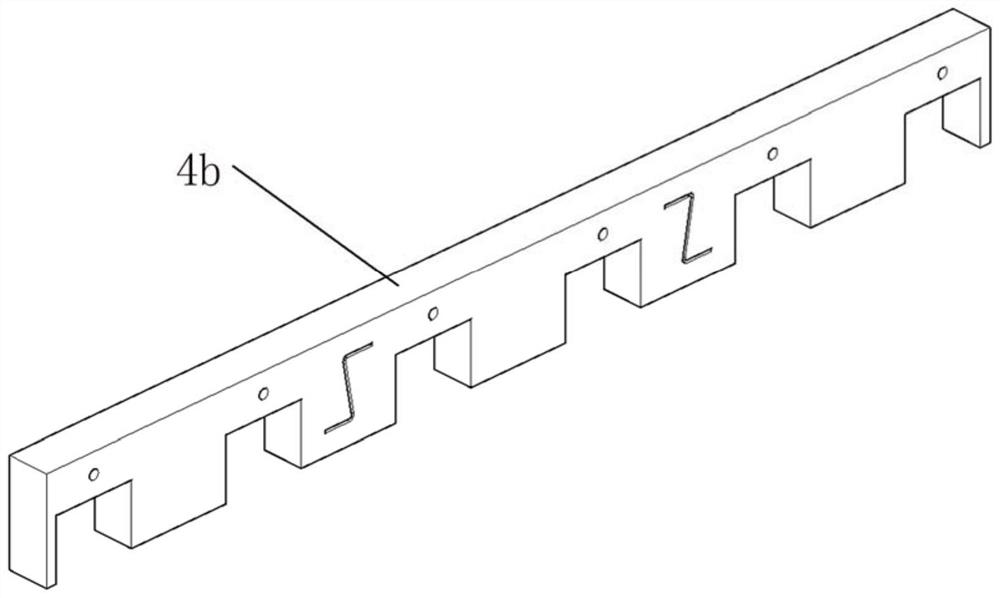

[0062] Such as Figure 1-6 As shown, the anti-cold and heat bridge node for cantilevered slab members provided in this embodiment includes: the main floor slab 2 in the room, the balcony slab 1 in the outdoor, the tension member 5 and the heat preservation box 4; The heat preservation box 4 is arranged on the top of the frame beam 3 and between the main floor 2 and the balcony slab 1; the tension member 5 passes through the heat preservation box 4, and the two ends of the tension member 5 extend into the main floor 2 and the balcony slab respectively. 1 is fixedly connected with the two inside; the heat preservation box 4 includes a box body 4a and a pressure member 4c; Heat transfer; the box body 4a is provided with a plurality of installation holes connecting the indoor and outdoor sides at intervals along its longitudinal direction; a plurality of the pressure receiving parts 4c are horizontally inserted into the installation holes for bearing the main body Pressure on flo...

Embodiment 2

[0084] This embodiment discloses a building. The outer wall and frame beams of the building are set up on the foundation. The piles used to support the foundation include concrete piles and steel pipe piles; on the horizontal projection plane, one or several steel piles The pipe pile is arranged between two adjacent concrete piles; in the depth direction, the length of the concrete pile is greater than the length of the steel pipe pile. The bottom of the concrete pile rests on a harder geological layer.

[0085] while referring to Figure 13-17 As shown, the steel pipe pile 100 includes: a hollow steel pipe 110 and a rotatable stiffener assembly 120; the rotatable stiffener assembly 120 includes: a support 122 and a rib plate 121; the support 122 is an arc plate, The rib plate 121 is fixed on the outer surface of the support member 122; the hollow steel pipe 110 is provided with a pre-opened hole 111; the rotatable stiffener assembly 120 is rotatably inserted into the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com