Diamond wire cutting liquid for solar silicon wafer as well as preparation method and application of diamond wire cutting liquid

A solar silicon wafer and diamond wire cutting technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problem of inability to meet the needs of large-size silicon wafer cutting, and achieves lower sewage treatment costs, good permeability and film-forming properties, The effect of reducing the amount of pure water used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative example 1-3

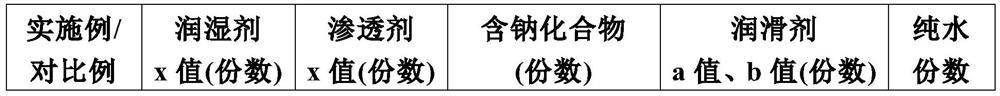

[0034] See Table 1 for the diamond wire cutting fluid components and their mass parts prepared in Examples 1-10 and Comparative Examples 1-3.

[0035] Table 1 embodiment 1-10 and comparative example 1-3

[0036]

[0037]

[0038] Note: The chemical formulas of wetting agent and penetrating agent are both RO(CH 2 CH 2 O) x H, R is C 10 h 21 , the chemical formula of the lubricant is HO(C 3 h 6 O) a (CH 2 CH 2 O) b H.

[0039] The preparation method of the diamond wire cutting fluid of embodiment 1-10 is as follows:

[0040] S1: At room temperature, add pure water to the reaction kettle after washing with pure water and start stirring;

[0041] S2: Add wetting agent, penetrating agent, lubricant, sodium-containing compound in sequence and keep stirring;

[0042] S3: The temperature of the reaction kettle is controlled at 35°C and stirred for 3 hours until it is completely dissolved;

[0043] S4: Stop stirring and let stand for 6-12 hours;

[0044] S5: A large-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com