Plasticizer-free high-hydrolysis-resistance TPU (thermoplastic polyurethane) and preparation method thereof

A plasticizer and high-resistance technology, applied in the field of plasticizer-free high hydrolysis-resistance TPU and its preparation, can solve problems such as unsolved soft TPU processing cycle, achieve excellent mechanical strength, and the preparation method is simple and easy to operate, which is beneficial to The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

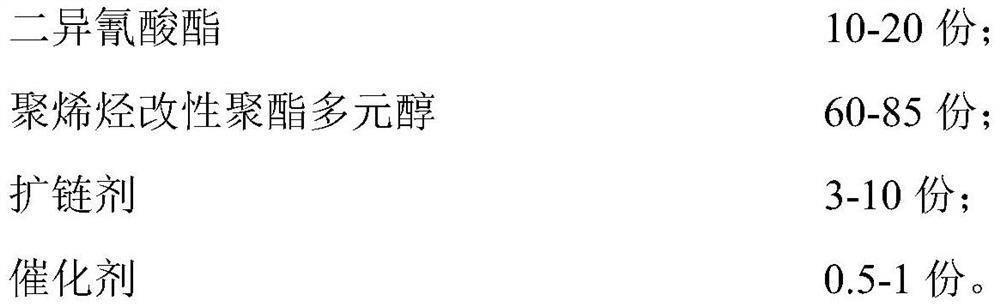

[0029] A plasticizer-free high hydrolysis-resistant TPU is made of the following raw materials in parts by mass:

[0030]

[0031] The preparation method comprises the following steps:

[0032] (1) Mix the polyolefin modified polyester polyol with the chain extender, then fully stir at 90°C to obtain a premix;

[0033] (2) Add the diisocyanate and the catalyst into the storage tank A, add the pre-mixture into the storage tank B, stir at a speed of 500r / min, vacuum dehydrate at 110°C, and inject into the twin-screw extruder;

[0034] (3) React in a twin-screw extruder at 140°C and granulate to obtain TPU particles; the temperature of the feeding section of the twin-screw extruder is 120°C, the temperature of the mixing section is 150°C, and the temperature of the extrusion section is 180°C , the head temperature is 170°C.

Embodiment 2

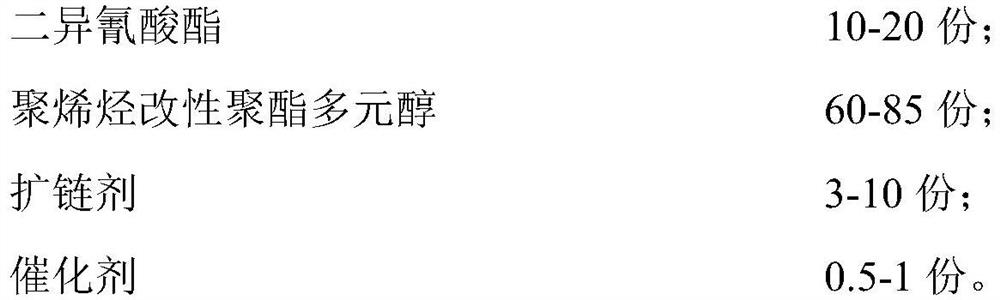

[0036] A plasticizer-free high hydrolysis-resistant TPU is made of the following raw materials in parts by mass:

[0037]

[0038] The preparation method comprises the following steps:

[0039] (1) Mix the polyolefin modified polyester polyol with the chain extender, then fully stir at 100°C to obtain a premix;

[0040] (2) Add the diisocyanate and the catalyst into the storage tank A, add the premixture into the storage tank B, stir at a speed of 400r / min, vacuum dehydrate at 110°C, and inject into the twin-screw extruder;

[0041] (3) At 130°C, react in a twin-screw extruder and granulate to obtain TPU particles; the temperature of the feeding section of the twin-screw extruder is 110°C, the temperature of the mixing section is 130°C, and the temperature of the extrusion section is 170°C °C, the head temperature is 160 °C.

Embodiment 3

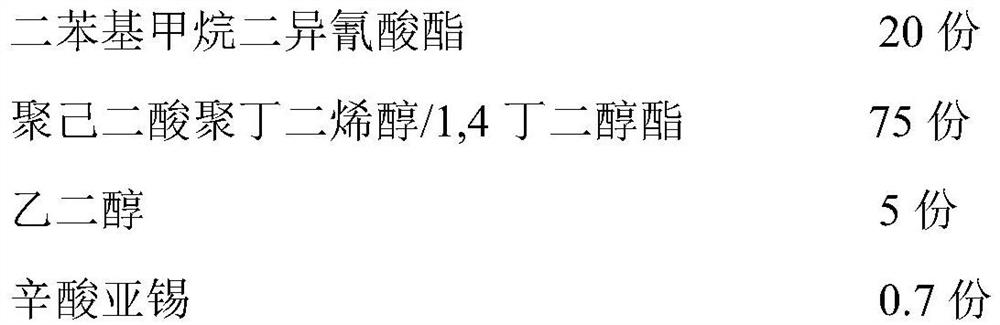

[0043] A plasticizer-free high hydrolysis-resistant TPU is made of the following raw materials in parts by mass:

[0044]

[0045] The preparation method comprises the following steps:

[0046] (1) Mix the polyolefin modified polyester polyol with the chain extender, then fully stir at 100°C to obtain a premix;

[0047] (2) Add the diisocyanate and the catalyst into the storage tank A, add the premixture into the storage tank B, stir at a speed of 600r / min, vacuum dehydrate at 110°C, and inject into the twin-screw extruder;

[0048] (3) React in a twin-screw extruder at 160°C, and granulate to obtain TPU particles; the temperature of the feeding section of the twin-screw extruder is 110°C, the temperature of the mixing section is 120°C, and the temperature of the extrusion section is 150°C. The head temperature is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com