Preparation method of boron, nitrogen and sulfur ternary doped reduced graphene oxide material

A technology of graphene and graphene, which is applied in the field of preparation of reduced graphene oxide materials, can solve the problems of affecting electron transmission and large resistance value, and achieve the effect of safe experimental operation, simple steps and improved carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

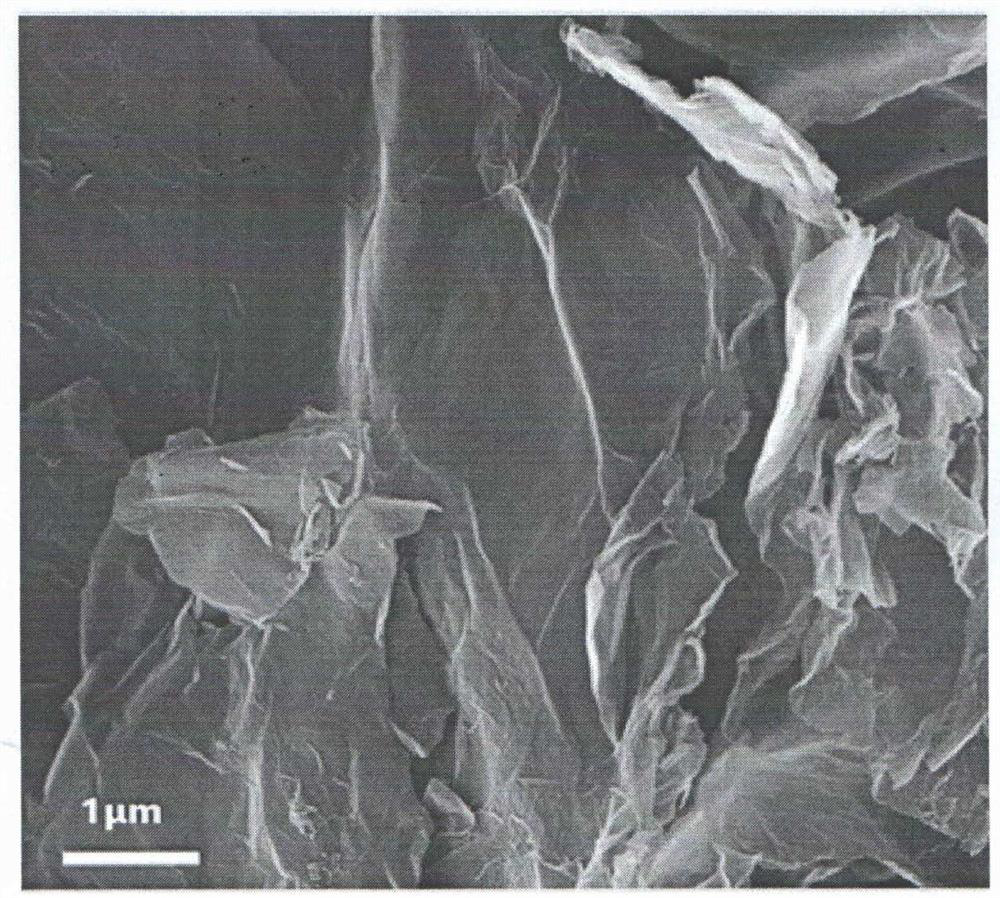

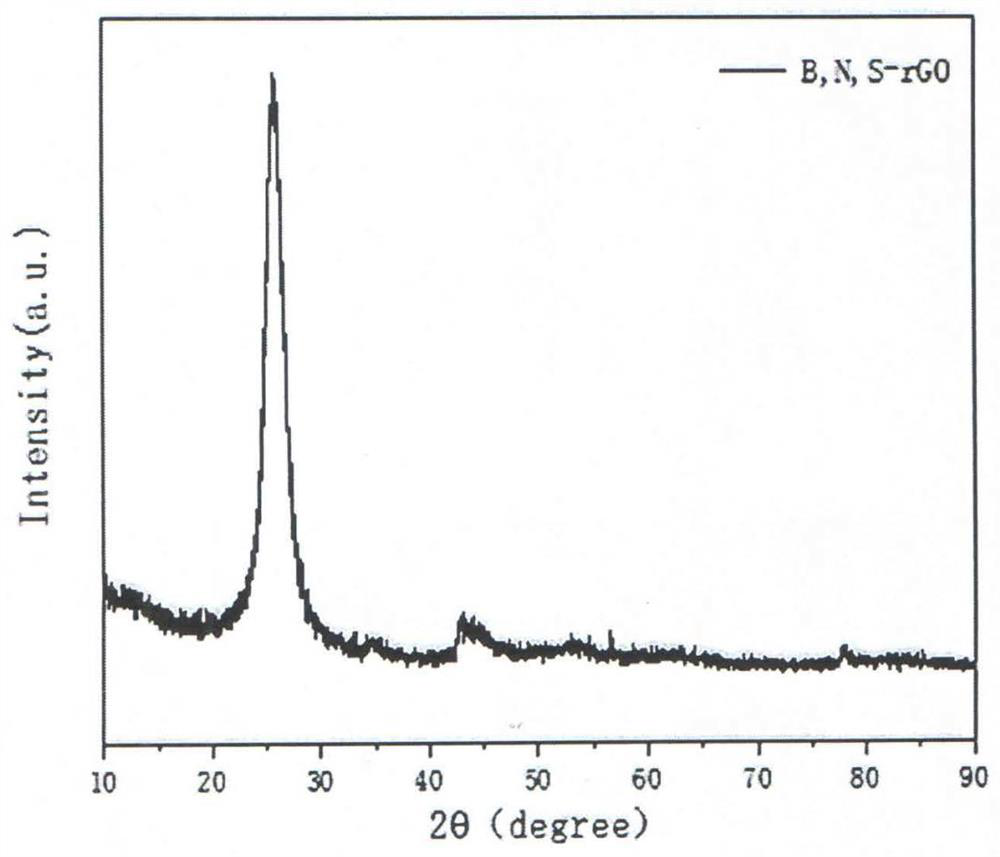

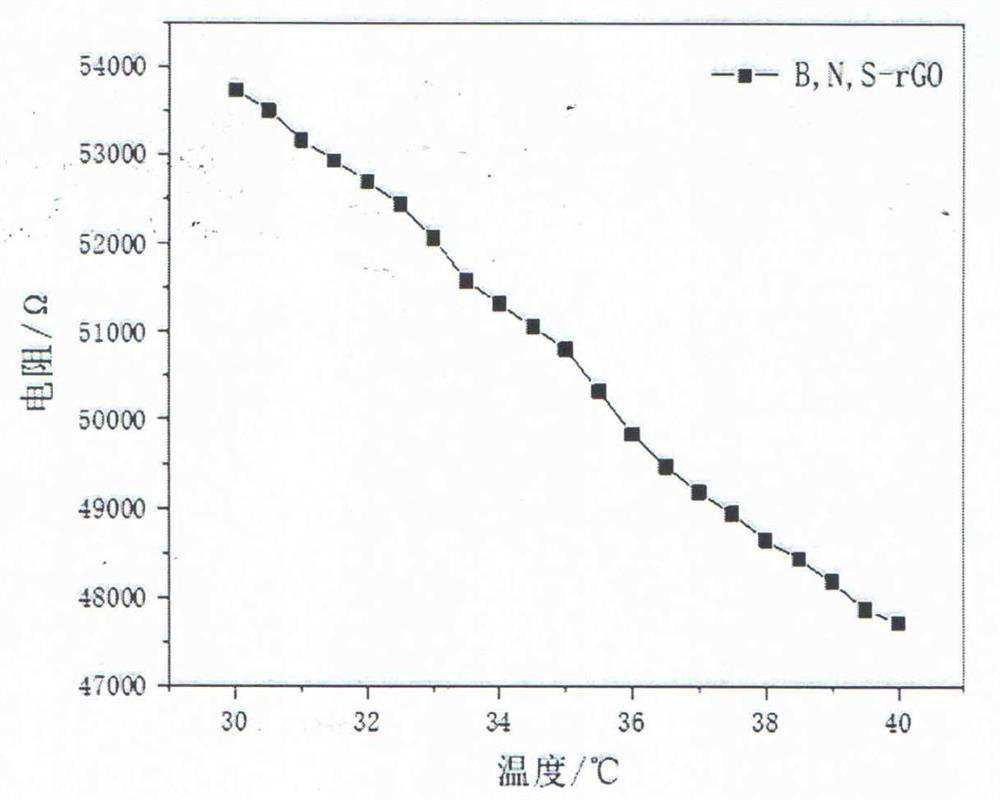

Image

Examples

Embodiment 1

[0026] Pretreatment of graphene oxide:

[0027] a. The graphene oxide liquid modified by the Hummers method was freeze-dried for 18 hours, placed in a vacuum drying oven at a temperature of 30°C, dried for 10 hours, and then placed in a mortar for grinding for 20 minutes to obtain fine and uniform particles Graphene oxide powder;

[0028] Configuration of the suspension:

[0029] b. Weigh 3g of thiourea and 1.2g of boric acid and put them in a beaker, add 50ml of deionized water and stir magnetically at room temperature for 15min. After the solid medicine in the cup is completely dissolved, a colorless and transparent solution is obtained; then Add 0.1 g of the graphene oxide powder processed in step a into the solution, and ultrasonically treat it for 1.5 h under the condition of an ice bath to obtain a graphene oxide suspension; wherein the mass fraction of thiourea in the mixed solution is 5.52%, and the mass fraction of boric acid The mass fraction of graphene oxide is a...

Embodiment 2

[0037] Pretreatment of graphene oxide:

[0038] a. The graphene oxide liquid improved by the Hummers method was freeze-dried for 20 hours, dried in a vacuum drying oven at a temperature of 35°C for 8 hours, and then placed in a mortar for grinding for 15 minutes to obtain fine and uniform oxidized particles. Graphene powder;

[0039] Configuration of the suspension:

[0040] b. Weigh 2g of thiourea and 1.1g of boric acid and put them in a beaker, add 50ml of deionized water and stir magnetically at room temperature for 20min. After the solid medicine in the cup is completely dissolved, a colorless and transparent solution is obtained, and then In step a, 0.1 g of the treated graphene oxide powder is added to the solution, and ultrasonically treated for 1 h under the condition of an ice bath, wherein the mass fraction of thiourea in the mixed solution is 3.76%, the mass fraction of boric acid is 2.07%, and the graphene oxide The mass fraction of is about 0.1880%; the mass rat...

Embodiment 3

[0048] Pretreatment of graphene oxide:

[0049] a. The graphene oxide liquid modified by the Hummers method was freeze-dried for 15 hours, dried in a vacuum drying oven at a temperature of 40°C for 12 hours, and then placed in a mortar for grinding for 10 minutes to obtain fine and uniform oxidized particles. Graphene powder;

[0050] Configuration of the suspension:

[0051] b. Weigh 1.5g of thiourea and 1g of boric acid and put them in a beaker, add 50ml of deionized water and stir magnetically at room temperature for 30min. After the solid medicine in the cup is completely dissolved, a colorless and transparent solution is obtained, and then Add 0.1 g of the graphene oxide powder processed in step a into the solution, and ultrasonically treat it for 2 h under the condition of an ice bath, wherein the mass fraction of thiourea in the mixed solution is 4.75%, the mass fraction of boric acid is 1.90%, and the mass fraction of graphene oxide The mass fraction is about 0.1901%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com