Soft granular feed and preparation method and application thereof

A feed and raw material technology, which is applied to the field of soft pellet feed and its preparation, can solve the problems of slow feeding of shrimps, loss of functional substances, influence of functional ingredients, etc., and achieves low production cost, promotion of rapid growth, and balanced nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

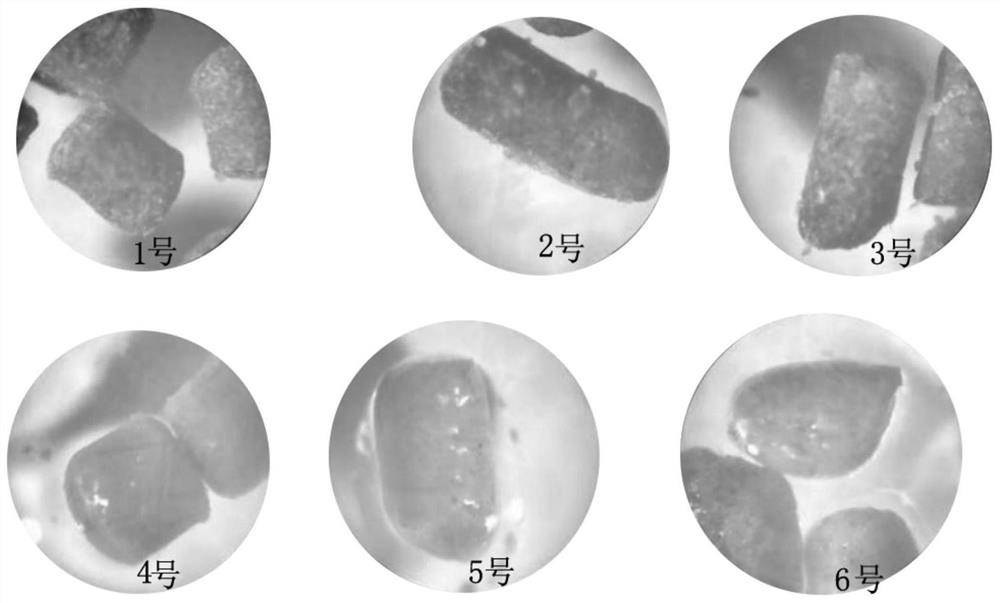

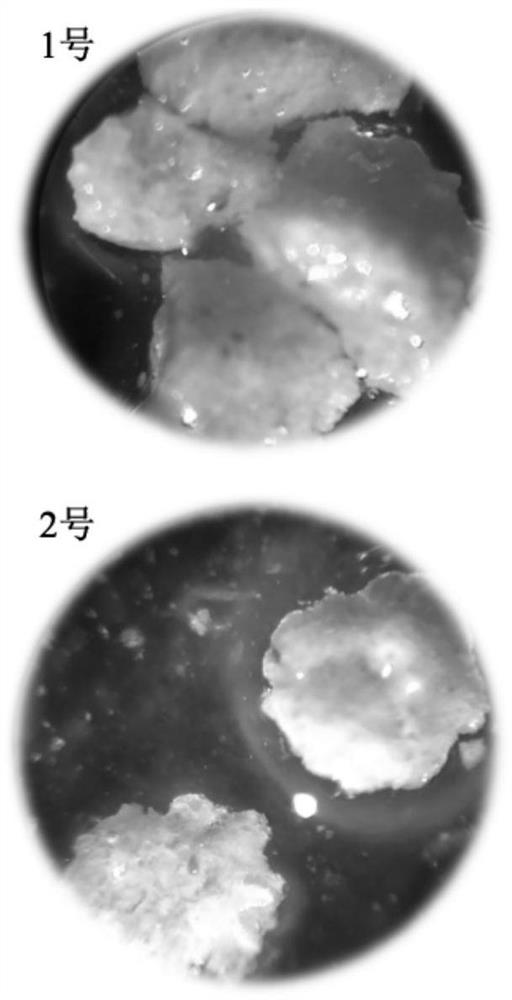

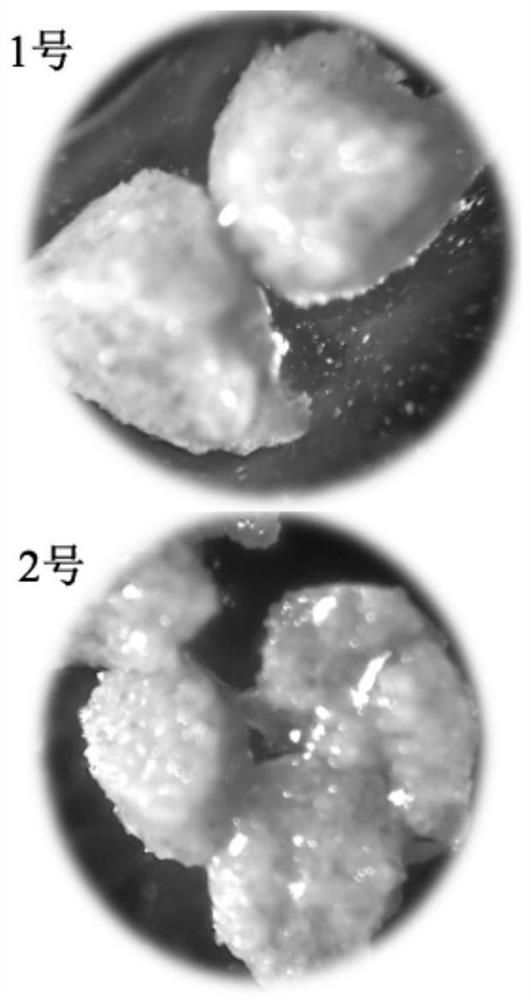

Image

Examples

Embodiment 1

[0054] A soft granule feed, comprising the following components: 33 parts of fish meal, 2 parts of squid hydrolyzate, 15 parts of krill meal, 12 parts of fermented soybean meal, 10 parts of high-gluten flour, 1.5 parts of calcium dihydrogen phosphate, and 2 parts of soybean lecithin , 0.2 parts of vitamins, 1 part of minerals, 2 parts of feed binder (xanthan gum: transglutaminase ratio of 1:3), 1 part of preservative, and 20.3 parts of functional substances.

[0055] The functional substances are: 300g / kg of lactic acid bacteria fermentation broth, 350g / kg of yeast fermentation broth, and 350g / kg of coagulans fermentation broth;

[0056] The composition of the antistaling agent is: streptomycin lactate 300g / kg, sodium diacetate 500g / kg, polylysine 200g / kg.

[0057] The composition of minerals is: ferrous sulfate 40000mg / kg, copper sulfate 6000mg / kg, manganese sulfate 10000mg / kg, zinc sulfate 40000mg / kg, yeast selenium 1000mg / kg, cobalt chloride 500mg / kg, potassium iodide 1000m...

Embodiment 2

[0065] A soft granule feed, comprising the following components: 27 parts of fish meal, 5 parts of squid hydrolyzate, 15 parts of krill meal, 15 parts of fermented soybean meal, 15 parts of high-gluten flour, 1.5 parts of calcium dihydrogen phosphate, and 2 parts of soybean lecithin , 0.2 parts of vitamins, 1 part of minerals, 3 parts of feed binder (xanthan gum: transglutaminase ratio of 1:3), 1 part of preservative, and 14.3 parts of functional substances.

[0066] Among them, the composition of functional substances is: Eucommia ulmoides extract 70g / kg, rhubarb extract 30g / kg, lactic acid bacteria fermentation stock solution 300g / kg, Clostridium butyricum fermentation stock solution 300g / kg, spore condensate fermentation stock solution 300g / kg.

[0067] The composition of the antistaling agent is: streptomycin lactate 300g / kg, sodium diacetate 500g / kg, polylysine 200g / kg.

[0068] The composition of minerals is: ferrous sulfate 40000mg / kg, copper sulfate 6000mg / kg, manganes...

Embodiment 3

[0076] A soft granule feed, comprising the following components: 28 parts of fish meal, 5 parts of squid hydrolyzate, 15 parts of krill meal, 15 parts of fermented soybean meal, 15 parts of high-gluten flour, 1.5 parts of calcium dihydrogen phosphate, and 2 parts of soybean lecithin , 0.2 parts of vitamins, 1 part of minerals, 3 parts of feed binder (xanthan gum: transglutaminase ratio of 1:1), 1 part of preservative, and 14.3 parts of functional substances.

[0077] Among them, the composition of functional substances is: Eucommia ulmoides extract 70g / kg, rhubarb extract 30g / kg, lactic acid bacteria fermentation stock solution 300g / kg, Clostridium butyricum fermentation stock solution 300g / kg, spore condensate fermentation stock solution 300g / kg.

[0078] The composition of the antistaling agent is: streptomycin lactate 300g / kg, sodium diacetate 500g / kg, polylysine 200g / kg.

[0079] The composition of minerals is: ferrous sulfate 40000mg / kg, copper sulfate 6000mg / kg, manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com