Local brush plating method of black chromium plating layer

A brush plating and black chrome technology, applied in the field of surface treatment of steel parts, can solve the problems of long construction period and cumbersome construction procedures, and achieve the effect of shortening construction period, avoiding isolation and damage, and avoiding rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

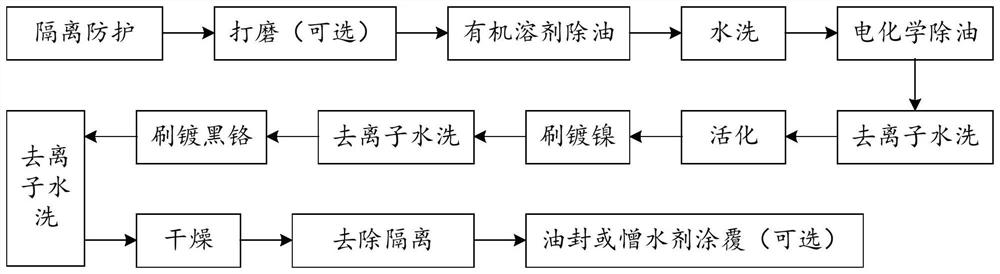

[0057] 1. Process flow and process description of partial brush plating of black chromium coating

[0058] 1.1 Black chromium brush plating process:

[0059] Isolation protection—grinding (according to the specific situation, as needed)—organic solvent degreasing—water washing—electrochemical degreasing—the first deionized water washing—activation—brush nickel plating—the second time Deionized water washing - black chrome plating - the third deionized water washing - drying - removal of isolation - oil seal or water repellent coating.

[0060] 1.2 Specific process description:

[0061] Process 1, isolation and protection

[0062] Before assembly or parts with special requirements are partially brushed with black chrome, plastic cloth, vinyl tape and other materials should be used to isolate and protect the non-brushed surfaces and gaps to avoid solution flow and retention.

[0063] Process 2, grinding

[0064] Use nylon sand stick or fine sandpaper to polish to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com