Tungsten cathode for molten salt electrolysis, preparation method of tungsten cathode and application of laser cladding technology

A technology of laser cladding and molten salt electrolysis, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of tungsten cathode corrosion, increased production cost, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

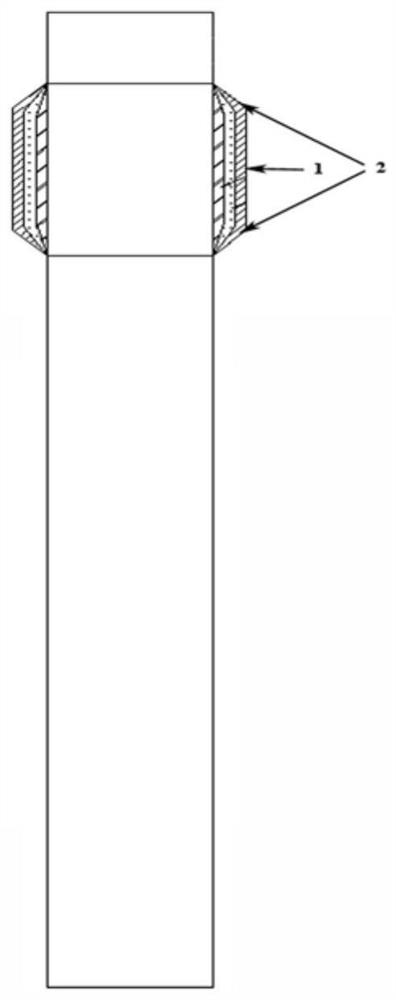

Image

Examples

Embodiment 1

[0046] (1) Preparation of corrosion-resistant metal composite materials

[0047] Weigh the raw materials according to the following ratio: C 0.03wt%, Si 2.0wt%, W 3.0wt%, Fe 5wt%, Mo14wt%, Cr 23wt%, ZrO 15wt%, B 0.6wt% and Ni of the balance; The sum of weight percentages of ingredients is 100wt%.

[0048] The above raw materials were placed in a planetary ball mill for refinement and mixing to obtain a corrosion-resistant metal composite material with a particle size of 300 mesh.

[0049] (2) Tungsten rod pretreatment

[0050] Take a tungsten rod with a diameter of 80mm and a length of 1000mm, and use a sandblasting process to perform surface purification and roughening treatment on the tungsten rod to obtain a tungsten rod with a surface sandblasting treatment.

[0051] (3) Laser cladding

[0052] Put the spherical pure copper powder with a particle size of 300 mesh, the 316L stainless steel spherical powder with a particle size of 300 mesh, and the anti-corrosion metal co...

Embodiment 2

[0060] Except for the following steps, the rest are the same as in Example 1.

[0061] (3) Laser cladding

[0062] Put the spherical pure copper powder with a particle size of 300 mesh, the 316L stainless steel spherical powder with a particle size of 300 mesh, and the anti-corrosion metal composite material with a particle size of 300 mesh respectively in the laser cladding equipment, and perform laser cladding on the tungsten rod that has been sandblasted on the surface , obtaining a tungsten cathode with a copper cladding layer, a stainless steel cladding layer and an anti-corrosion metal cladding layer;

[0063] Among them, the laser cladding copper adopts a cladding process with high power and low powder feeding rate. The specific process parameters are set as: power output ratio 82%, powder feeding speed 16g / min, shielding gas volume: 18L / min, powder feeding gas: 1.4 L / min, cladding thickness 1.8mm;

[0064] Laser cladding stainless steel adopts a cladding process with...

Embodiment 3

[0068] Except for the following steps, the rest are the same as in Example 1.

[0069] (3) Laser cladding

[0070] Put the spherical pure copper powder with a particle size of 500 mesh, the 316L stainless steel spherical powder with a particle size of 500 mesh and the anti-corrosion metal composite material with a particle size of 500 mesh respectively in the laser cladding equipment, and perform laser cladding on the tungsten rod that has been sandblasted on the surface (the cladding area is the zone between 120~250mm apart from this tungsten rod end), obtains the tungsten cathode with copper cladding layer, stainless steel cladding layer and corrosion-resistant metal cladding layer;

[0071] Among them, the laser cladding copper adopts a cladding process with high power and low powder feeding rate. The specific process parameters are set as: power output ratio 88%, powder feeding speed 18g / min, shielding gas volume: 18L / min, powder feeding gas: 1.6 L / min, cladding thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com