System and method for preparing high-concentration biomass carbon source from kitchen waste

A biomass carbon source, kitchen waste technology, applied in the methods of supporting/fixing microorganisms, biochemical equipment and methods, sterilization methods, etc., can solve the secondary pollution, the effective COD equivalent is not high, and the transportation radius is limited. It can improve the utilization rate of organic matter, improve the utilization rate of heat source and save external energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

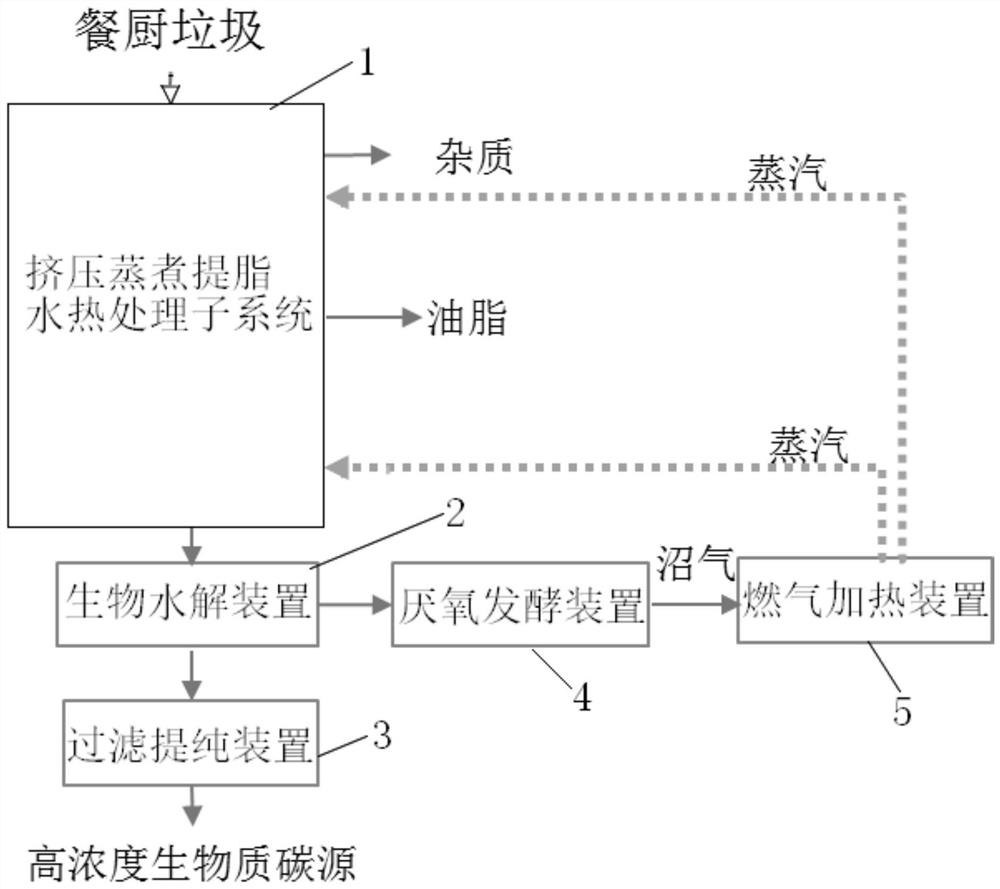

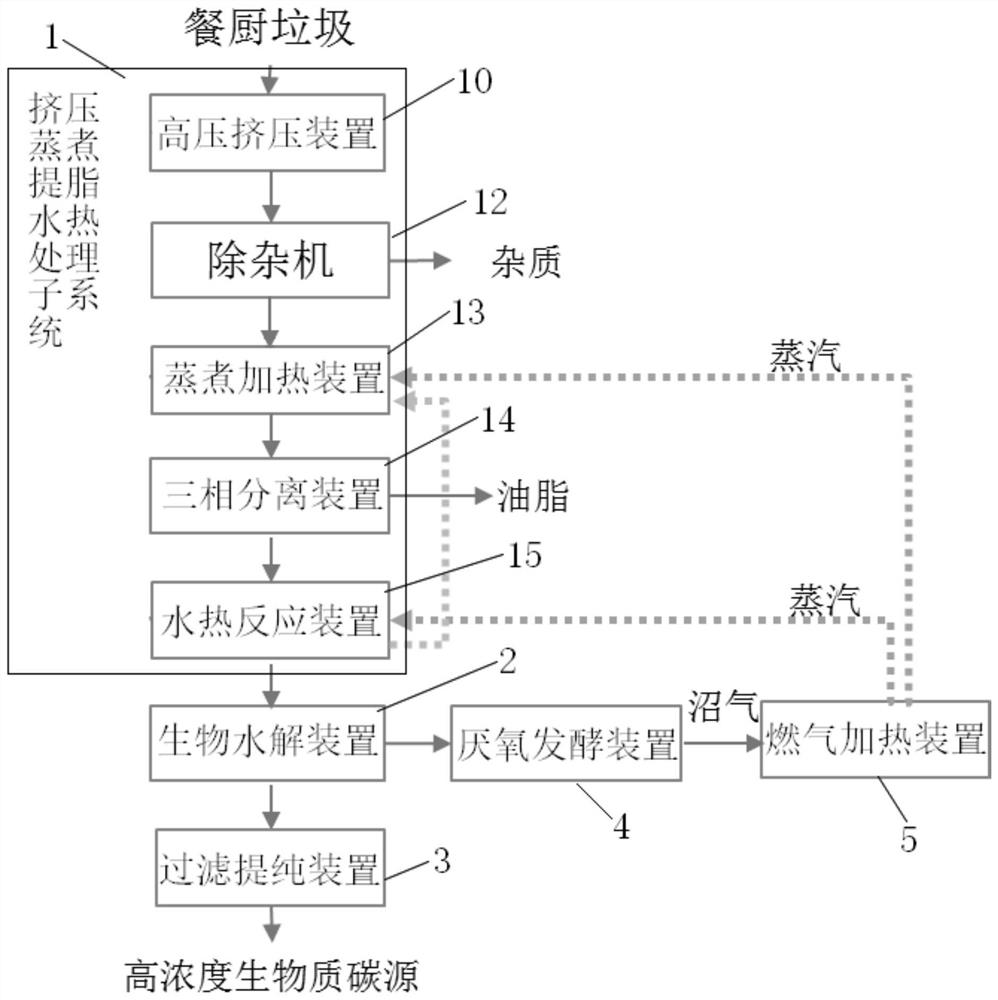

[0115] This embodiment provides a system for preparing a high-concentration biomass carbon source from kitchen waste, the system includes: a hydrothermal treatment subsystem for extrusion cooking and fat extraction, a biological hydrolysis device, a filtration and purification device, anaerobic fermentation device and a gas heating device ; wherein, the extrusion cooking fat extracting hydrothermal treatment subsystem is composed of a high-pressure extrusion device, a decontamination machine, a cooking heating device, a three-phase separation device and a hydrothermal device connected in sequence (see figure 2 ), this structural extrusion cooking fat extraction hydrothermal treatment subsystem can process food waste through high pressure-cooking-hydrothermal treatment, forming a "big hydrothermal system", which uses food waste to prepare high-concentration biomass The method of carbon source, comprises the following steps (see Figure 5 ):

[0116] First of all, the food was...

Embodiment 2

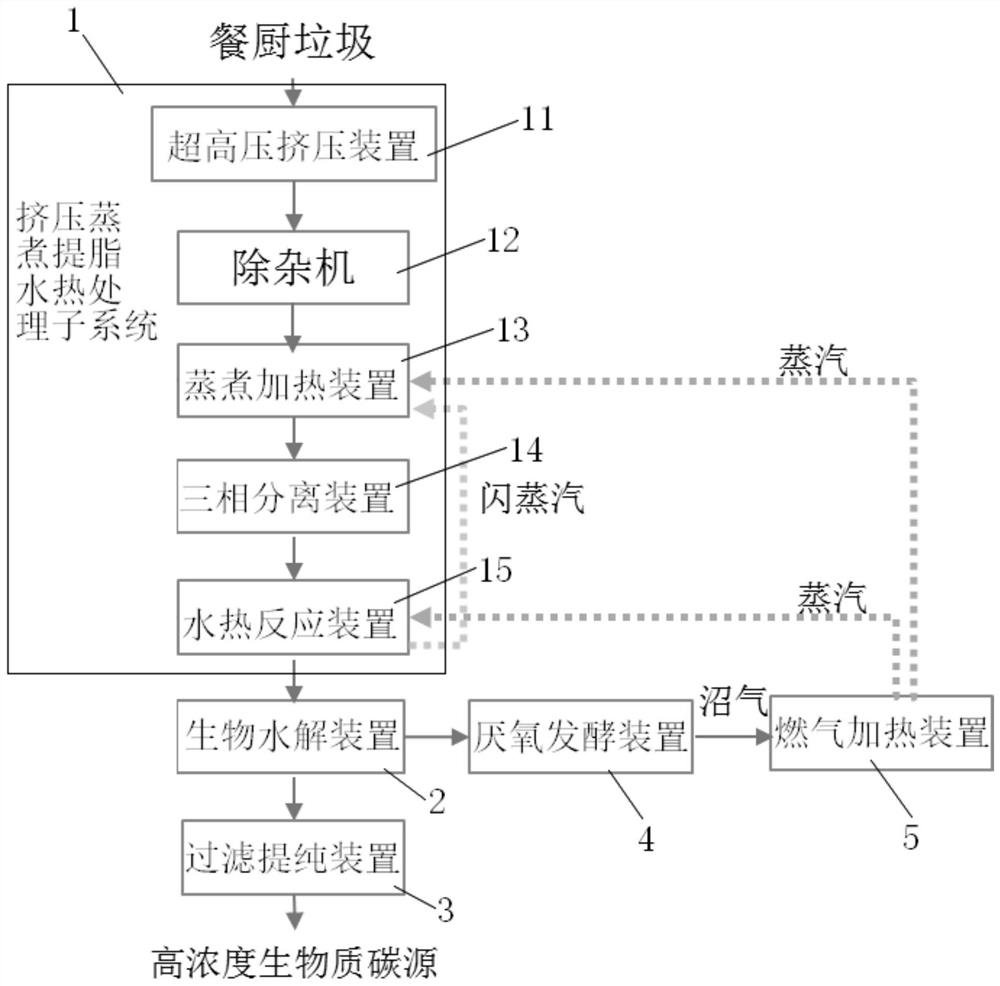

[0124] This embodiment provides a system for preparing a high-concentration biomass carbon source from kitchen waste, the system includes: a hydrothermal treatment subsystem for extrusion cooking and fat extraction, a biological hydrolysis device, a filtration and purification device, anaerobic fermentation device and a gas heating device ; wherein, the extrusion cooking fat extracting hydrothermal treatment subsystem is composed of an ultra-high pressure extrusion device, impurity remover, cooking heating device, three-phase separation device and hydrothermal device connected in sequence (see image 3 ), this structural extrusion cooking fat extraction hydrothermal treatment subsystem can process food waste through ultra-high pressure-cooking-hydrothermal treatment, forming a "disguised phase hydrothermal system", which uses food waste to prepare high-concentration The method for biomass carbon source, comprises the following steps (see Figure 6 ):

[0125] First of all, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com