Micro-emulsified methanol diesel dispersing agent and application thereof

A technology of micro-emulsification and dispersing agent, applied in the petrochemical field, can solve the problems of high preparation cost, low calorific value of biodiesel, high cost, etc., and achieve the effects of simple operation, wide ratio range and high stability in the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

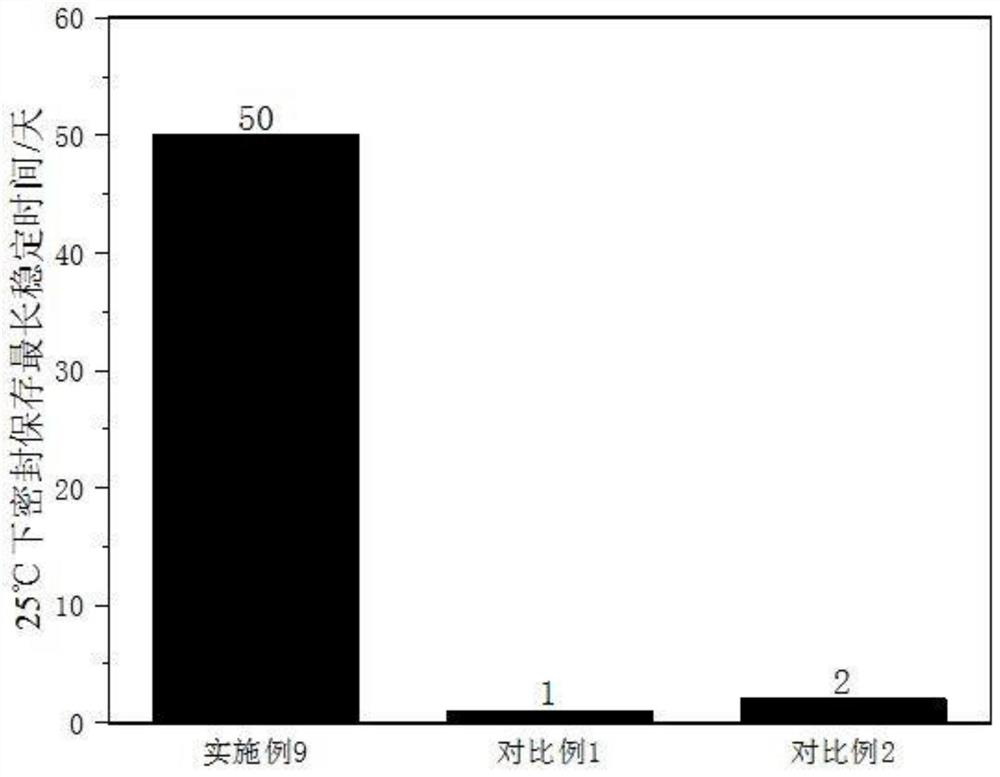

Examples

Embodiment 1

[0020] Take 0.03kg of capric acid and heat it until it is completely melted, then add it to 0.95kg of hydrogenated diesel oil, 0.05kg of methanol, 0.0005kg of Span80, 0.01kg of isohexyl alcohol and 0.0005kg of monomethyl suberate and stir evenly until it is clear and transparent, that is, A micro-emulsified methanol diesel with a methanol weight fraction of 5w% was obtained. Its minimum critical temperature is 20°C, and it can be stored at room temperature for more than 45 days.

Embodiment 2

[0022] Take 0.06kg of myristic acid and heat it until it is completely melted, then add it to 0.90kg of straight-run diesel oil, 0.10kg of methanol, 0.0005kg of Tween80, 0.01kg of isohexyl alcohol and 0.0005kg of monoethyl suberate and stir until it is clear and transparent, that is, A micro-emulsified methanol diesel with a methanol weight fraction of 10w% was obtained. Its minimum critical temperature is 9°C, and it can be stored at room temperature for more than 45 days.

Embodiment 3

[0024] Take 0.04kg of linolenic acid and heat it until it is completely melted, then add it to 0.85kg of hydrogenated diesel oil, 0.15kg of methanol, 0.0003kg of Span80, 0.0003kg of Tween80, 0.04kg of linoleic acid, 0.01kg of n-heptanol and 0.0006kg of monopropyl suberate Stir evenly until it is clear and transparent, that is, micro-emulsified methanol diesel with a methanol weight fraction of 15w% is prepared. Its minimum critical temperature is 8°C, and it can be stored at room temperature for more than 40 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com