Keyway machining jig for motor core

A technology of iron core and keyway, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting work efficiency and inconvenient actual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

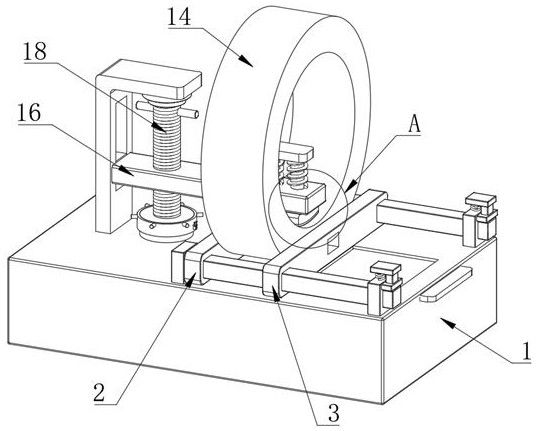

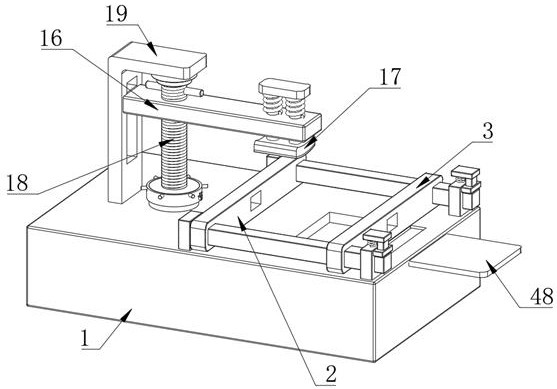

[0035] Embodiment one, by Figure 1 to Figure 9 Given, the present invention comprises a control box body 1, the top of the control box body 1 is provided with a fixed clamping plate 2 and a movable clamping plate 3, the top inner wall of the control box body 1 is provided with a positioning hole 4, and the top of the control box body 1 The inner wall is provided with a first rectangular hole 5, the control box body 1 is provided with a movable adjustment plate 6, and the top of the movable adjustment plate 6 extends into the first rectangular hole 5, and the control box body 1 is provided with a first threaded rotating column 15, The first threaded rotating column 15 runs through the movable adjustment plate 6, and the connection mode between the first threaded rotating column 15 and the movable adjusting plate 6 is threaded connection, and the control box body 1 is provided with a drive unit that matches the first threaded rotating column 15, The top of the movable adjustmen...

Embodiment 2

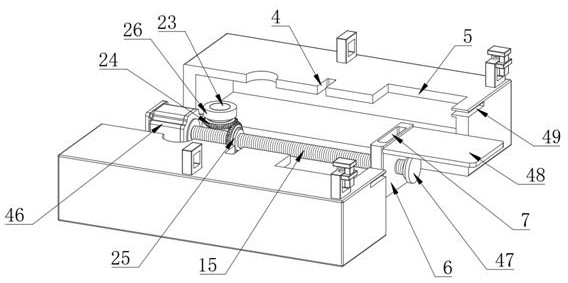

[0037] Embodiment two, on the basis of embodiment one, by image 3 , Figure 4 , Figure 6 , Figure 7 with Figure 8 Given, the engagement adjustment assembly includes a rotating shaft 23 disposed below the second threaded rotating column 18, the rotating shaft 23 runs through the top inner wall of the control box body 1, and the rotating shaft 23 is connected to the penetration of the control box body 1 through a second bearing 26 , and the bottom of the rotating shaft 23 is fixedly connected with the first bevel gear 24 located in the control box body 1, and the outside of the first threaded rotating column 15 is provided with a second bevel gear 25, and the second bevel gear 25 is connected to the first bevel gear. A threaded rotating column 15 is fixedly connected, and the first bevel gear 24 and the second bevel gear 25 are meshed, the bottom of the second threaded rotating column 18 is fixedly connected with a fixed plate 28, and the top of the rotating shaft 23 is f...

Embodiment 3

[0039] Embodiment three, on the basis of embodiment two, by Figure 6 , Figure 7 with Figure 8Given, the anti-rotation assembly includes a movable ring 27 sleeved on the outside of the second threaded rotating column 18, a positioning tube 29 is sleeved outside the movable ring 27, and the positioning tube 29 is fixedly connected with the movable ring 27, and the inner wall of the positioning tube 29 Two first grooves 30 are provided, the first groove 30 is provided with a first limiting column 31, and the fixed plate 28 is provided with two second grooves 32, and one end of the first limiting column 31 is located on the second In the groove 32, and one end of the first limiting post 31 is connected to the inner wall of one side of the second groove 32 through a compression spring 33, and a pressing plate 34 is arranged in the first groove 30, and one side of the pressing plate 34 is fixedly connected There is a pressing column 35, and one end of the pressing column 35 run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com