Preparation and application of metal vanadium efficient adsorption-reduction material taking waste green tea residues as raw material

A technology for green tea residues and raw materials, applied in the fields of environmental engineering and groundwater pollution control, can solve problems such as environmental pollution and waste of biological resources, and achieve the effects of high adsorption capacity, strong reducing ability, and reducing the frequency of replacement of fillers and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of green tea dregs biochar loaded zero-valent iron material is as follows:

[0025] 1) crush the green tea dregs and pass through a 40-mesh sieve, and place in a tube furnace (N 2 atmosphere) at a constant temperature of 300°C for 2 hours, and take it out after cooling. Wash with deionized water and absolute ethanol several times, and dry for 20 h. Grind and dry the biochar to pass through 100 mesh, and set aside.

[0026] 2) Weigh 5.85g biochar and add to 100mL FeSO 4 In the solution, the mass ratio of iron to carbon is 1, sealed with a parafilm and then shaken and impregnated in a constant temperature shaking box.

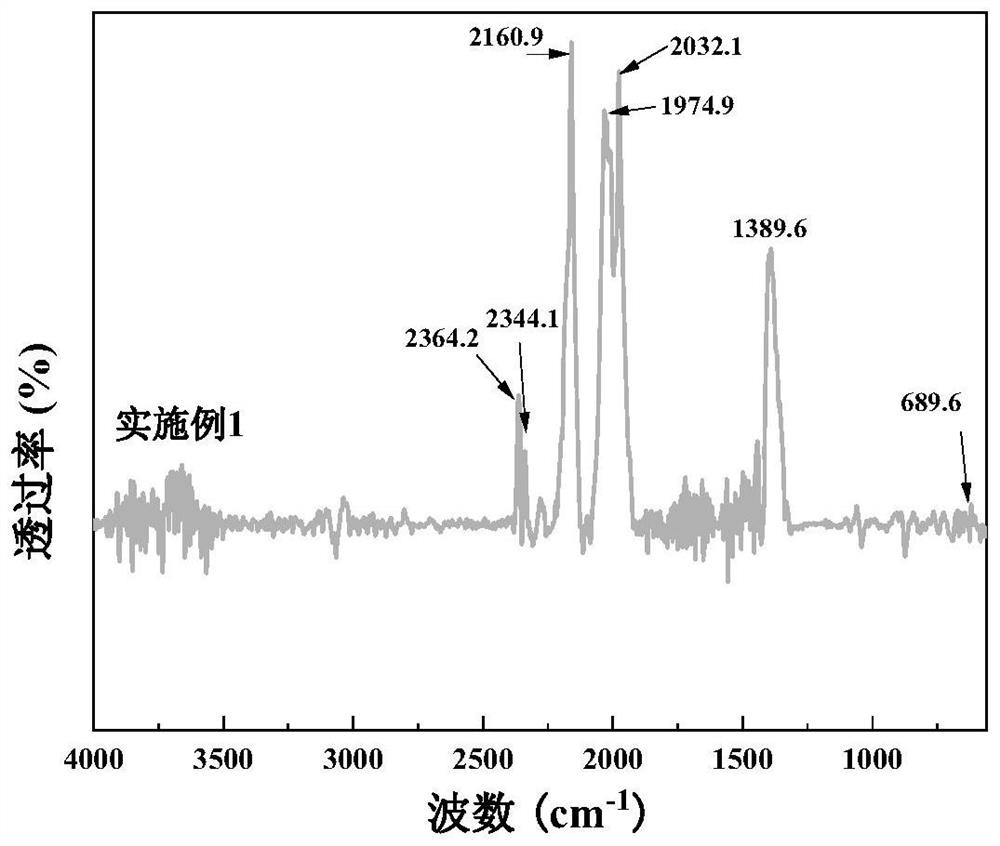

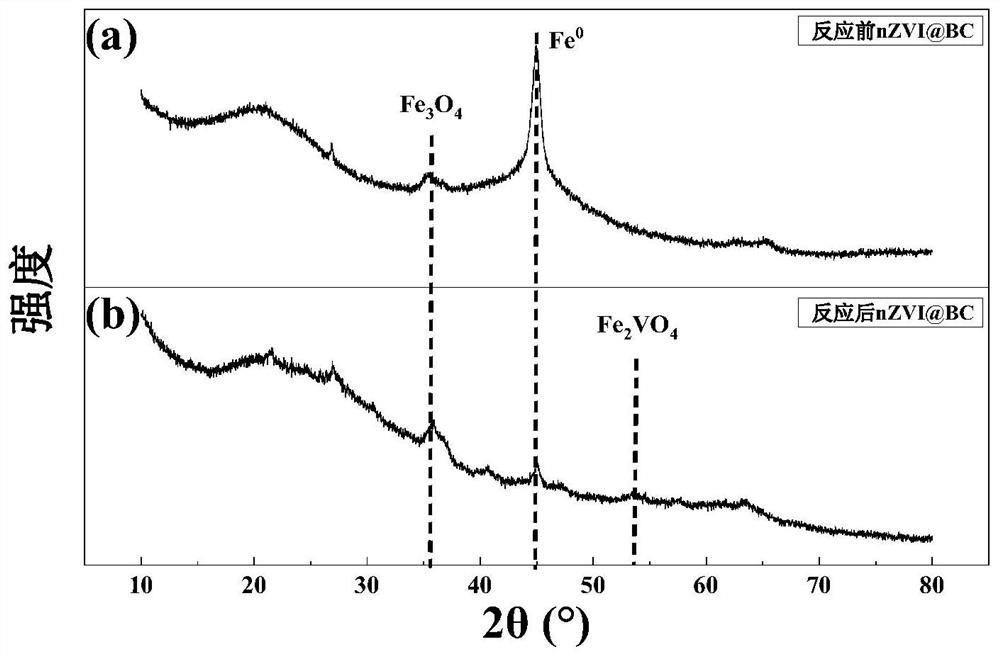

[0027] 3) Stir the impregnated mixture fully under the protection of nitrogen, add 50mL of absolute ethanol, and slowly drop 1mol L -1 The sodium borohydride solution was stirred for a period of time and then centrifuged to separate the precipitate. After washing, put it in a vacuum drying oven to dry for 12 hours, take it out an...

Embodiment 2

[0030] Repeat the preparation process of Example 1, the difference is that in step 1), the green tea residue is placed in the tube furnace (N 2 atmosphere) at a constant temperature of 500°C for 2 hours.

Embodiment 3

[0032] Repeat the preparation process of Example 1, the difference is that in step 1), the green tea residue is placed in the tube furnace (N 2 atmosphere) at a constant temperature of 700°C for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com