Method for predicting alpha sub-phase morphology through titanium alloy beta parent phase crystal orientation

A crystal orientation, titanium alloy technology, applied in chemical process analysis/design, special data processing applications, instruments, etc., can solve the problems of inconvenient popularization and application, complex process, etc., to achieve simplicity and practicability, good comparative analysis, The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

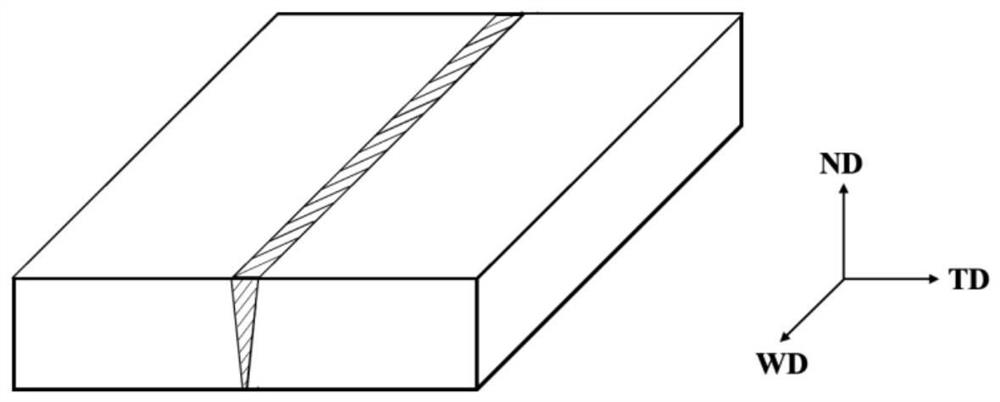

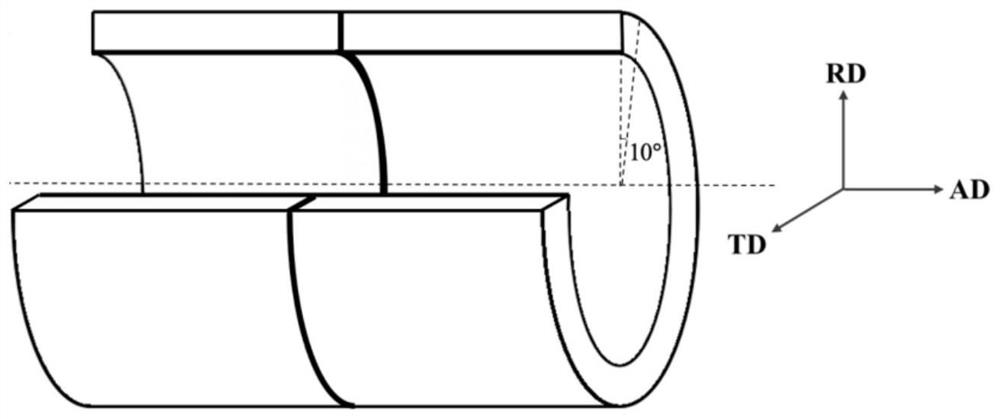

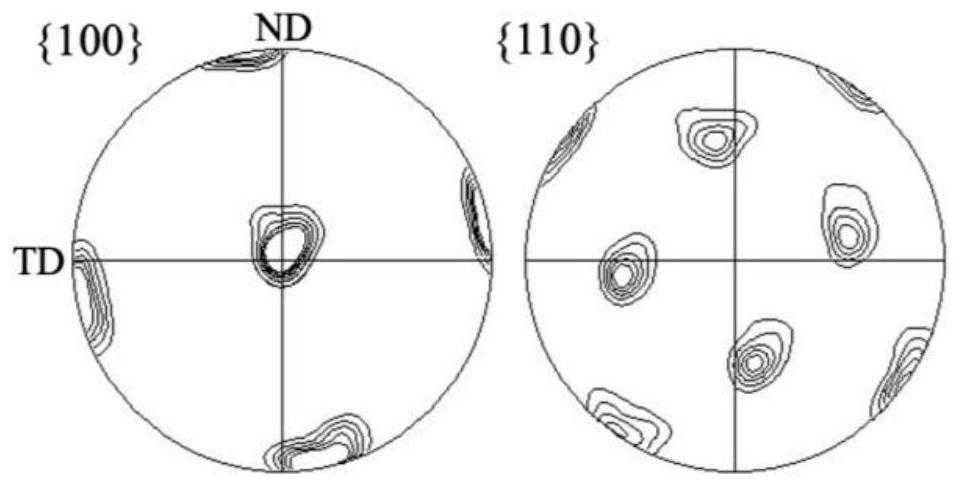

[0034] For TC25G titanium alloy homogeneous electron beam welded joints and inertial friction welded joints, the samples are subjected to solution annealing at 960°C, 2h / AC+540°C, 6h / AC heat treatment system; then the weld seam is the center, and the size is 20mm ×15mm×10mm sample for microstructure characterization and micro-domain orientation characterization; such as figure 1 figure 2 Establish the sample coordinate system. The electron beam welding joint coordinate system is composed of the welding direction (WD), the normal direction (ND) and the cross-section direction (TD) perpendicular to each other. The ND-TD section is used as the observation plane; the inertial friction welding ring piece coordinates The tangential direction (TD) is perpendicular to the axial direction (AD) and radial direction (RD) respectively, and the AD-TD section is used as the observation surface; the sample surface is ground and polished to a mirror surface and then used Kroll reagent (96ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com