Nano-fluid energy-absorbing material and preparation method and application thereof

An energy-absorbing material and nanofluid technology, applied in the field of energy-absorbing materials, can solve the problems of cumbersome surface treatment process and complicated preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

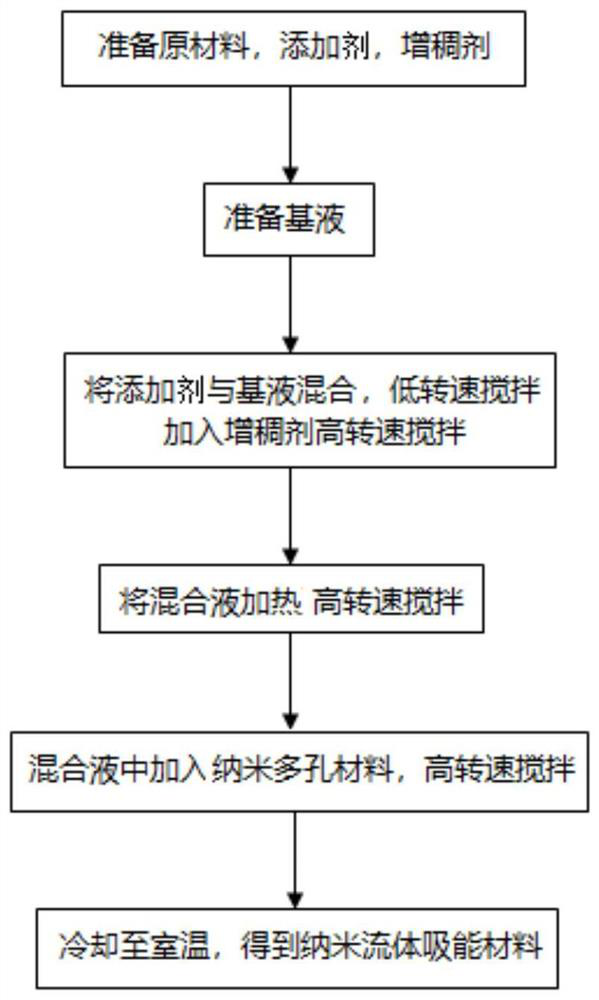

[0030] Such as figure 1 As shown, the preparation method of a kind of nanofluid energy-absorbing material provided by the present invention comprises:

[0031] Step 1: Add additives (sodium chloride, sodium carbonate, potassium chloride, potassium carbonate, sodium hexametaphosphate and cetyltrimethylammonium chloride powder in mass ratio 1: (2.9~5.1) One or more of them) mixed with base liquid (deionized water, lubricating oil, ethylene glycol, glycerin or one or more combinations of the above-mentioned alcohol-water mixed solvents) to obtain mixed solution A;

[0032] Step 2: Stir at a low speed of 75-100r / min for 30-60min, add a thickener (agar, dextrin, sodium carboxymethylcellulose, polyvinylpyrrolidone) with a mass ratio of 1:0.1 to the mixed solution A. One or several combinations), stirring at a high speed of 150-200r / min to obtain the mixed solution B;

[0033] Step 3: Under high-speed stirring conditions, heat the mixed solution B to 40-60°C; add a mass ratio of 1:...

Embodiment 1

[0036] 1) Mix the additives sodium chloride, potassium chloride and sodium hexametaphosphate with the base liquid deionized water according to the mass ratio of 1:2.9 to obtain the mixed liquid A;

[0037] 2) Stir at a low speed of 80r / min for 50min, add thickener agar with a mass ratio of 1:0.1 to the additive in the mixed solution A, and stir at a high speed of 150r / min to obtain the mixed solution B;

[0038] 3) Under high-speed stirring conditions, heat the mixed solution B to 40°C; add nanoporous molecular sieves ZSM-5 and ZSM-22 with a mass ratio of 1:0.5 to the mixed solution B, and stir at a high speed of 185r / min for 90min, Mix evenly and cool to room temperature to obtain nanofluid energy-absorbing material.

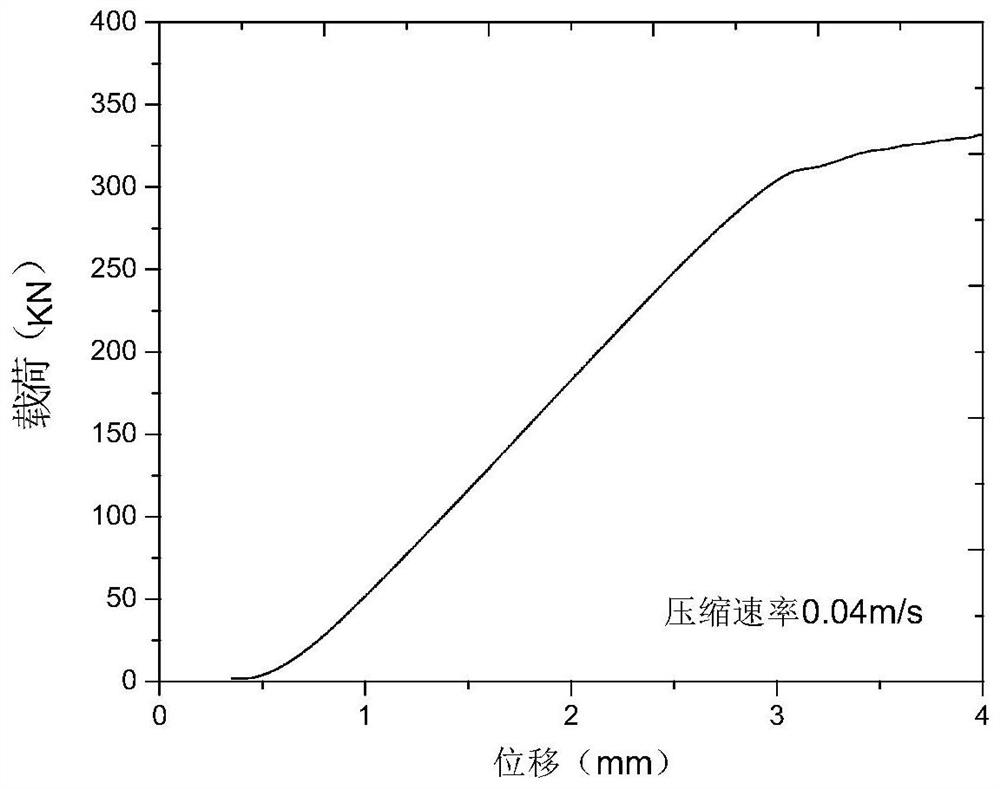

[0039] Embodiment 1 energy absorption density test curve sees figure 2 As shown, the pore size of the nanoparticles in the nanofluid is 0.56 nanometers, the distribution range is narrow, the dispersion is good, and there is no agglomeration phenomenon. The e...

Embodiment 2

[0041] 1) Mix the additives sodium carbonate and potassium carbonate with the base liquid deionized water + ethylene glycol solution according to the mass ratio of 1:3.5 to obtain the mixed solution A;

[0042] 2) Stir at a low speed of 75r / min for 40min, add a thickener dextrin with a mass ratio of 1:0.1 to the additive in the mixed solution A, and stir at a high speed of 160r / min to obtain a mixed solution B;

[0043] 3) Under the condition of high-speed stirring, heat the mixed solution B to 50°C; add the nanoporous alumina material with a mass ratio of 1:0.5 to the mixed solution B, stir at a high speed of 200r / min for 60min, mix well and cool to At room temperature, the nanofluid energy-absorbing material is obtained.

[0044] The pore size of the nanoparticles in the nanofluid is 0.50 nanometers, the distribution range is narrow, the dispersion is good, and there is no agglomeration phenomenon. The energy absorption density can reach 96J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com